Rapid cooling equipment for sintered powder metallurgy manufactured product

A rapid cooling and powder metallurgy technology, applied in the field of cooling equipment, can solve the problems of long cooling time and low efficiency, and achieve the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

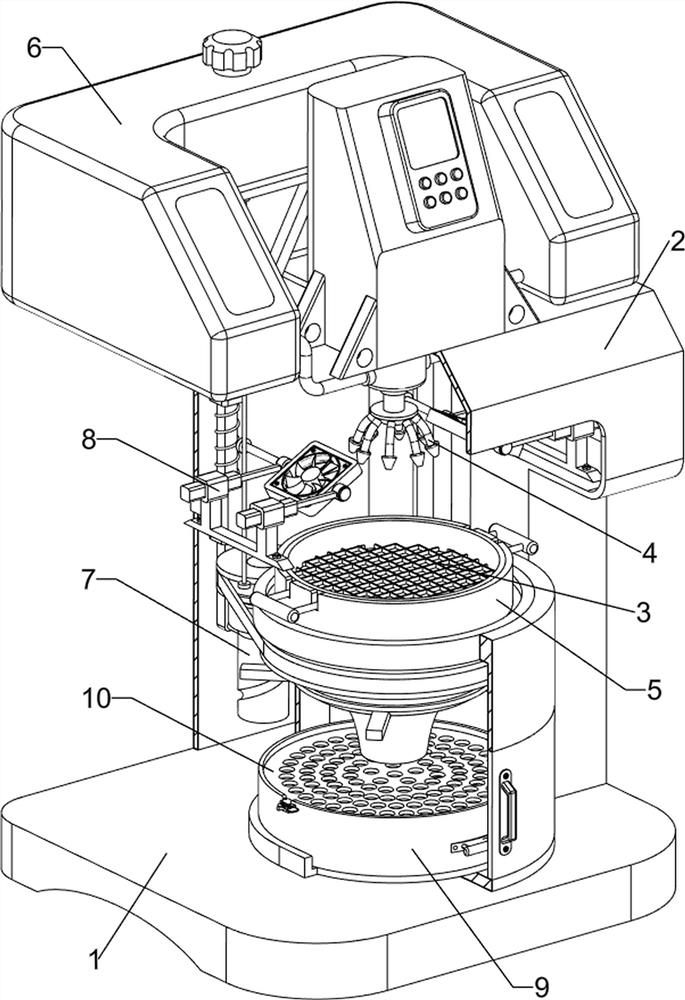

[0030] A rapid cooling equipment for powder metallurgy products after sintering, such as Figure 1-4 As shown, it includes a base 1, a casing 2, a placement net 3, a nozzle 4, a placement assembly 5 and a water spray assembly 6, the upper rear side of the base 1 is provided with a casing 2, the upper middle of the base 1 is provided with a placement assembly 5, and the placement assembly 5 A placement net 3 is placed on it, and a water spray assembly 6 is provided on the upper side of the shell 2, and a nozzle 4 is provided on the water spray assembly 6.

[0031] The placement assembly 5 includes a support frame 501, a rotating cylinder 502, a handle 503 and a frame door 504. The upper middle part of the base 1 is provided with a support frame 501, and the upper side of the support frame 501 is rotatably provided with a rotating cylinder 502. The rotating cylinder 502 The upper side is placed with placing net 3, and placing net 3 left and right sides is provided with grip 503,...

Embodiment 2

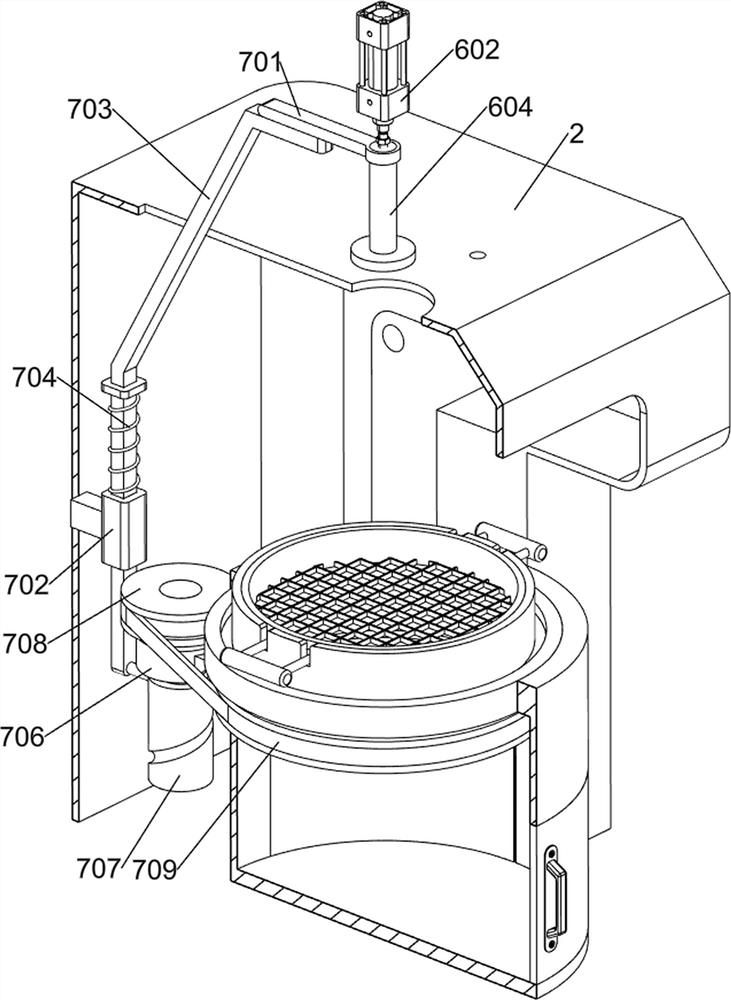

[0035] On the basis of Example 1, such as Figure 5-10 As shown, a rotating assembly 7 is also included, and the rotating assembly 7 includes a pressing rod 701, a guide block 702, a first sliding rod 703, a first spring 704, a first supporting block 706, a groove cylinder 707, a transmission wheel 708 and a transmission belt 709 , the upper rear side of the piston rod 604 is provided with a pressure rod 701, the inner rear side of the casing 2 is provided with a guide block 702, and the guide block 702 is slidably provided with a first slide rod 703, and the first slide rod 703 and the pressure rod 701 are mutually Cooperate, the first spring 704 is connected between the first slide bar 703 and the guide block 702, the first spring 704 is sleeved on the first slide bar 703, the support frame 501 rear side is provided with the first support block 706, the first support block 706 is provided with a grooved cylinder 707 in a rotating manner, and the grooved cylinder 707 cooperat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com