Metal lithium powder composite material and preparation method thereof, silicon-oxygen negative electrode and lithium ion battery

A lithium-ion battery and metal lithium powder technology, which is applied in metal lithium powder composite materials and its preparation, silicon-oxygen negative electrodes, and lithium-ion batteries, can solve problems that are not conducive to improving the first efficiency of silicon-oxygen battery systems and lithium powder pre-lithiation Problems such as poor material stability and difficulty in industrial application have achieved the effect of improving preparation safety, improving first-time efficiency, and improving application flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

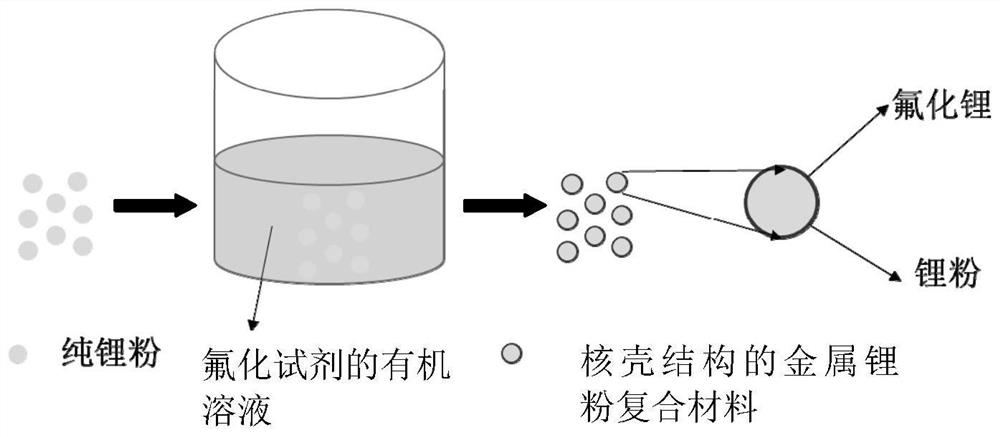

[0035] as attached figure 1 As shown, the first aspect of the embodiments of the present invention provides a method for preparing a metal lithium powder composite material, comprising the following steps:

[0036] S10. Obtain the organic solution of metal lithium powder and fluorinating reagent;

[0037] S20. Under an inert atmosphere at a temperature of 0° C. to 90° C., the lithium metal powder and the organic solution of the fluorinating reagent are mixed and reacted to obtain a lithium metal powder composite material.

[0038] The preparation method of the lithium metal powder composite material provided by the first aspect of the present invention uses a fluorinating agent as a raw material for the stabilization treatment of the lithium metal powder, and directly mixes the lithium metal powder with the fluorinated lithium powder under an inert atmosphere at a temperature of 0°C to 90°C The organic solvent of the reagent is mixed and reacted, and the fluorine element in t...

Embodiment 1

[0060] A lithium metal powder composite material, comprising preparation steps:

[0061] 1) Ball milling of lithium powder: 5g of 500-mesh lithium powder was ball milled for 2 hours under an argon atmosphere;

[0062] 2) Preparation of mixed solution of n-hexane fluorinating reagent: add 90% n-hexane to a single-necked round bottom flask, then add 10% fluorinating reagent (perfluorotripropylamine), seal the obtained solution and put it in a refrigerator for storage.

[0063] 3) Preparation of stable lithium powder: Add 100g of the mixed solution of the above-mentioned fluorinating reagents, and then add 5g of ball-milled lithium powder into the prepared diluted solvent, under argon atmosphere, at a temperature of 23±3°C The reaction was stirred for 2h.

[0064] 4) Drying: The prepared stable lithium powder was washed with n-hexane for 3 times, and then dried in an oven in an argon atmosphere to obtain a highly stable metal lithium powder composite material.

Embodiment 2

[0066] A lithium metal powder composite material, comprising preparation steps:

[0067] 1) Ball milling of lithium powder: 5g of 400-mesh lithium powder was ball milled for 2 hours under an argon atmosphere;

[0068] 2) Preparation of n-hexane fluorinating reagent mixed solution: add 85% benzene to a single-necked round bottom flask, then add 15% fluorinating reagent (perfluorodecalin), seal the obtained solution and put it in a refrigerator for storage.

[0069] 3) Preparation of stable lithium powder: Add 100g of the mixed solution of the above-mentioned fluorinating reagents, and then add 5g of ball-milled lithium powder into the prepared diluted solvent, under argon atmosphere, at a temperature of 23±3°C The reaction was stirred for 4h.

[0070] 4) Drying: The prepared stable lithium powder was washed with n-hexane for 3 times, and then dried in an oven in an argon atmosphere to obtain a highly stable metal lithium powder composite material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com