A high-strength and tough aluminum alloy with various mixed crystal structures induced by micro-shear bands and its preparation method and application

A technology of micro-shearing and aluminum alloy, which is applied in the direction of metal rolling and process efficiency improvement, can solve the problems of slowing performance improvement, low research alloy degree, and rising cost, and achieves low material cost and simple experimental scheme , The effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Prepare Al-2Zn high strength and toughness alloy profiles with a length of 10 cm and a thickness of 2 mm.

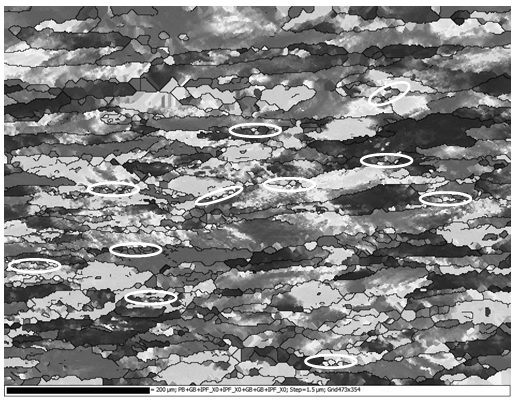

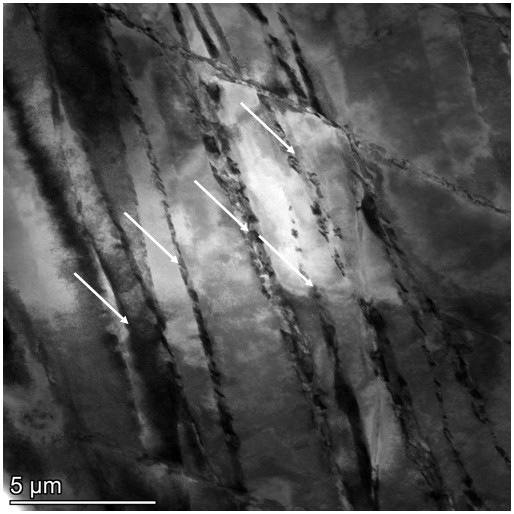

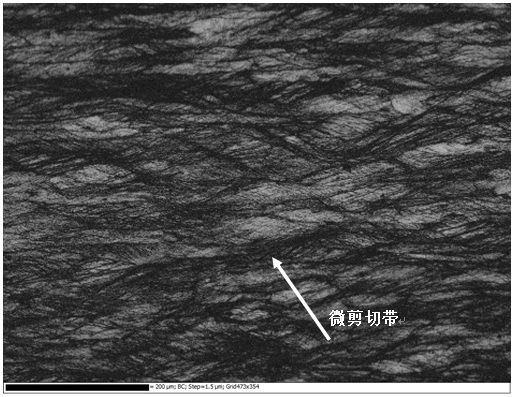

[0034] A micro-shear belt induces the formation of a high-strength and tough aluminum alloy with a variety of mixed crystal structures, including multiple micro-shear belts, a large number of isoaxial nanocrystals and layered nanocrystals around the micro-shear belt, and a micro-grained crystal-free zone retains microcrystals to form a mixed-crystal structure structure in which isoaxial nanocrystals, layered nanocrystals and microcrystals coexist.

[0035] The aluminum alloy is An Al-Zn alloy, the zinc content in the Al-Zn alloy is 2wt%, and the rest is aluminum.

[0036] The preparation method of a micro-shear belt induces the formation of a high-strength and tough aluminum alloy with a variety of mixed crystal structures as follows:

[0037](1) High-temperature homogeneous solid solution treatment: the homogenization treatment of casting Al-2Zn insulation at 475 °C ...

Embodiment 2

[0043] Prepare Al-5Zn-1Mg high strength and toughness alloy profiles with a length of 10 cm and a thickness of 2 mm.

[0044] A micro-shear belt induces the formation of a high-strength and tough aluminum alloy with a variety of mixed crystal structures, including multiple micro-shear belts, a large number of isoaxial nanocrystals and layered nanocrystals around the micro-shear belt, and a micro-grained crystal-free zone retains microcrystals to form a mixed-crystal structure structure in which isoaxial nanocrystals, layered nanocrystals and microcrystals coexist.

[0045] The aluminum alloy is Al-Zn-Mg alloy, the zinc content in The Al-Zn-Mg alloy is 5wt, the magnesium content is 1wt, and the rest is aluminum.

[0046] Its preparation method is as follows:

[0047] (1) High-temperature homogeneous solid solution treatment: the homogenization treatment of casting Al-5Zn-1Mg at 475 °C for 6h to eliminate macroscopic segregation of elements in the cast structure and achieve high sol...

Embodiment 3

[0053] Prepare Al-6Zn-1Mg high strength and toughness alloy profiles with a length of 10 cm and a thickness of 2 mm. The aluminum alloy is Al-Zn-Mg alloy, Al-Zn-Mg alloy has a zinc content of 6wt, a magnesium content of 1wt, and the rest is aluminum.

[0054] Its preparation method is as follows:

[0055] (1) High-temperature homogeneous solid solution treatment: the homogenization treatment of casting Al-6Zn-1Mg at 475 °C for 6h to eliminate macroscopic segregation of elements in the cast structure and achieve high solid solution of alloying elements;

[0056] (2) The alloy obtained in step (1) is directly extruded for 4 consecutive times ECAP at homogenization temperature;

[0057] (3) Multi-channel room temperature rolling: the above-mentioned extruded samples are rolled at multiple times at room temperature, of which the single-channel down pressure is 5%; the total down pressure is 50%; there is no obvious micro-crack on the sample surface;

[0058] (4) Artificial aging: 20h ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com