Floating oil recovery system of emulsion for aluminum wire rod hot rolling

A technology for oil slick recovery and emulsification, which is applied in the direction of lubricating compositions, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

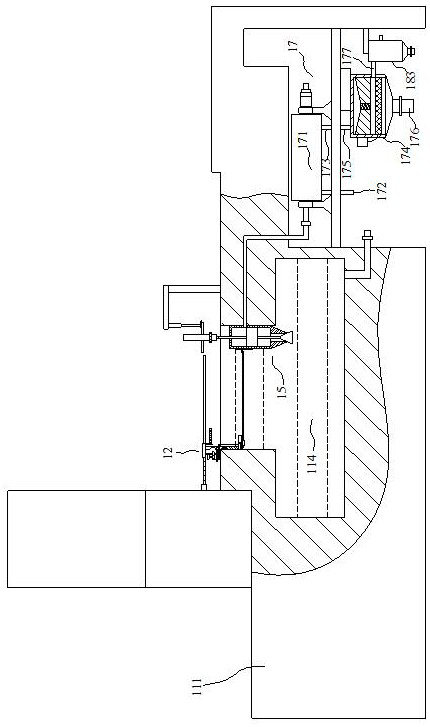

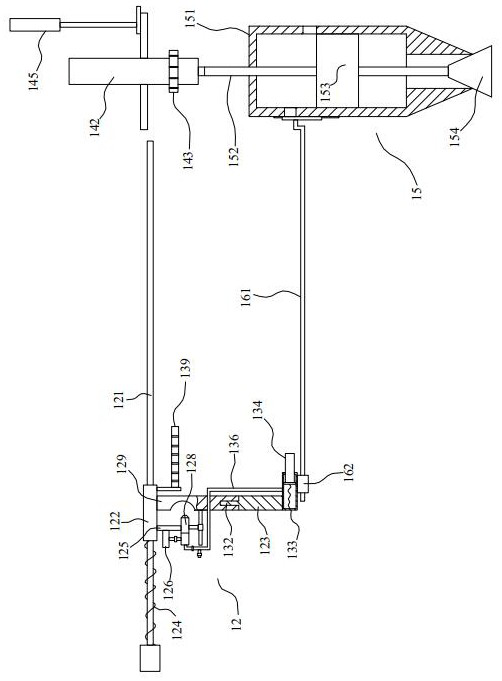

[0037] Please refer to Figure 1-Figure 6 , the present embodiment provides an emulsion oil recovery system for hot rolling of aluminum wire rods, which mainly includes: a cutting mechanism 11 , an oil skimming mechanism 12 , an oil suction mechanism 15 and an emulsion breaking mechanism 17 .

[0038] The fuselage 111 is provided with an oil receiving tank 114 , and the used emulsion is stored in the oil receiving tank 114 .

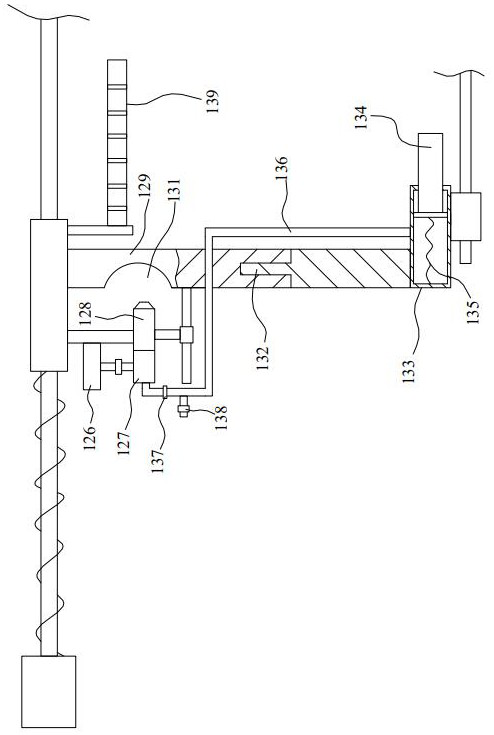

[0039]The oil skimming mechanism 12 includes a first guide rod 121 , a first sliding sleeve 122 and an oil throwing plate 123 . The first guide rod 121 is arranged laterally above the oil receiving groove 114 , the first sliding sleeve 122 is slidably connected to the first guide rod 121 , and the oil catching plate 123 is connected to the first sliding sleeve 122 . The first sliding sleeve 122 can move along the axial direction of the first guide rod 121 under the drive of the traverse assembly.

[0040] The oil suction mechanism 15 includes a suction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com