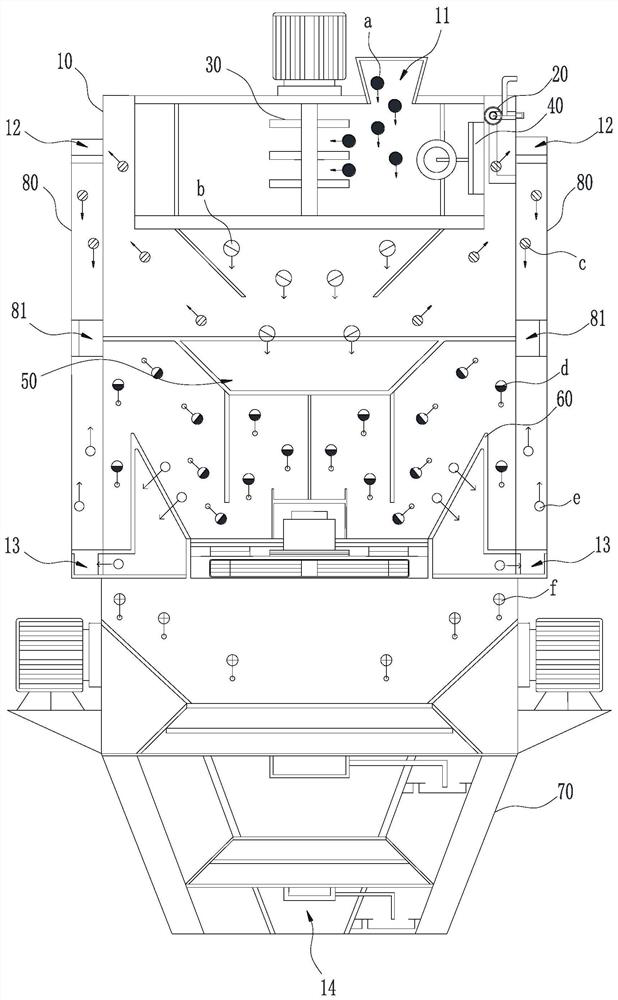

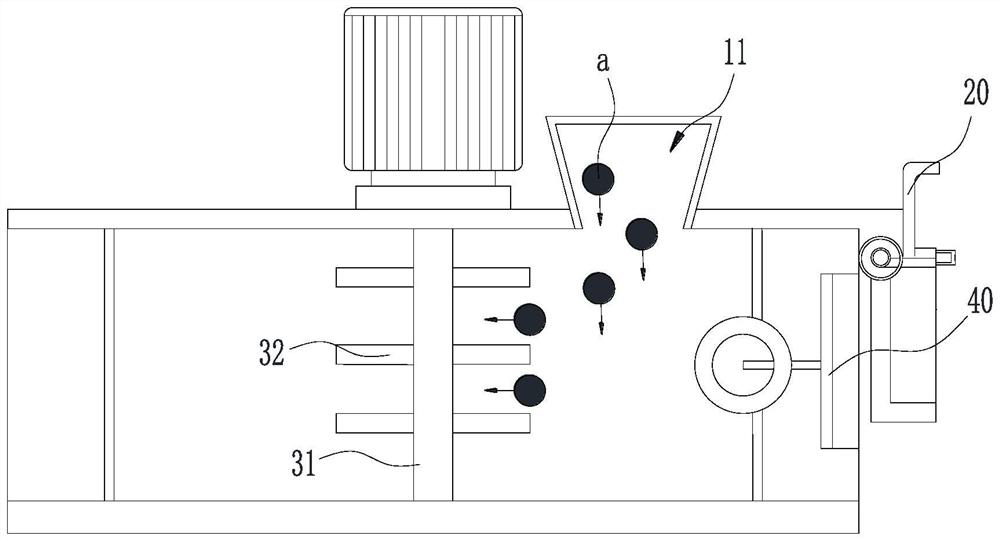

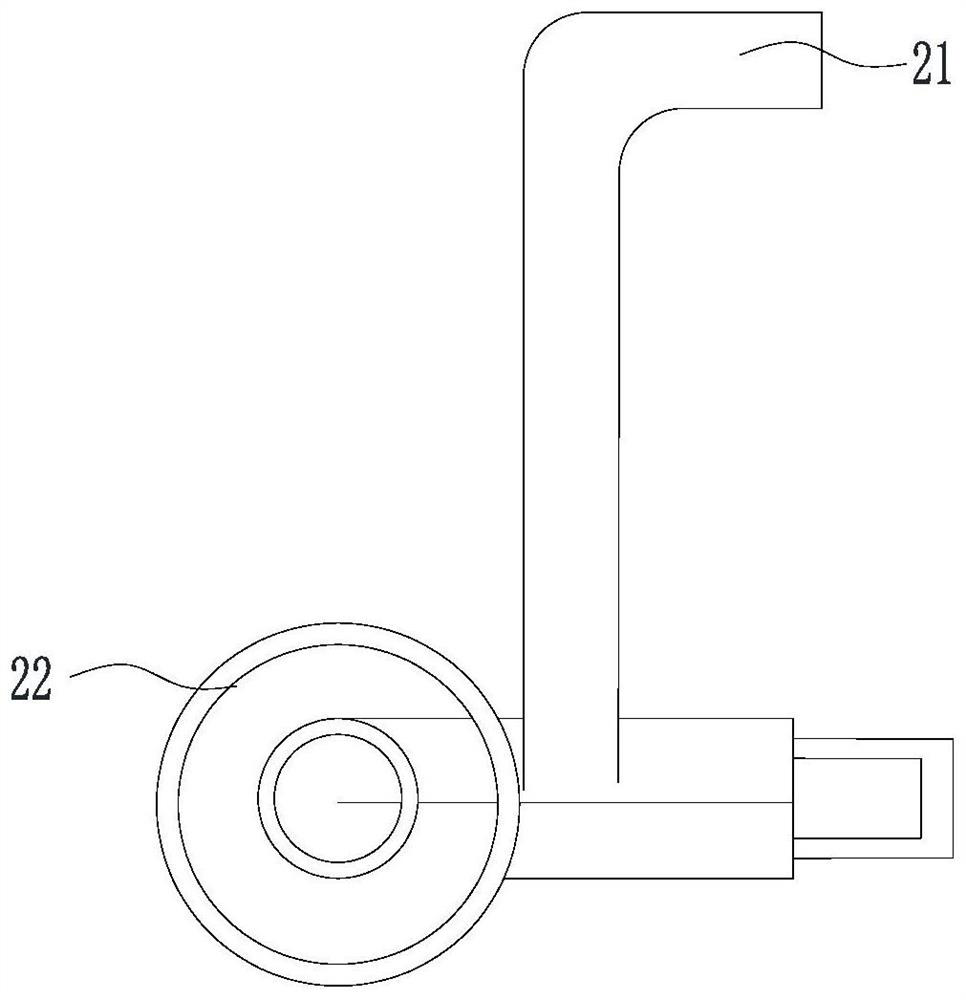

Flocculation grading dehydration device

A dewatering device and flocculation technology, which is applied in centrifugal separation of water/sewage treatment, water/sewage treatment, water/sewage multi-stage treatment, etc. problem, to achieve the effect of improving dehydration effect and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] In order to make the purpose, technical solutions and advantages of the present invention clearer, the present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments. All other embodiments obtained below all belong to the protection scope of the present invention.

[0058] Coal slime water is produced in the process of wet coal preparation. Coal slime water is a mixture of coal particles and water. In order to make coal slime water meet environmental protection requirements, further solid-liquid separation treatment of coal slime water is required. The method for separating solid-liquid from coal slime is mainly flocculation and graded dehydration, and its purpose is to achieve:

[0059] (1) By adding chemicals, the suspended solids in the material water are settled and separated in the form of larger particles or loose flocs, economically and effectively realizing the closed-circuit circulation of coal slime wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com