Rhombic roller type sieving machine

A sieving machine and diamond-shaped technology, which is applied in the direction of sieving, solid separation, grille, etc., can solve the problems of plate level reduction, affecting index performance, impact, etc., and achieve the effect of increasing efficiency and adequacy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention can be explained in more detail with reference to the following examples; however, it should be noted that the present invention is not limited to the following examples.

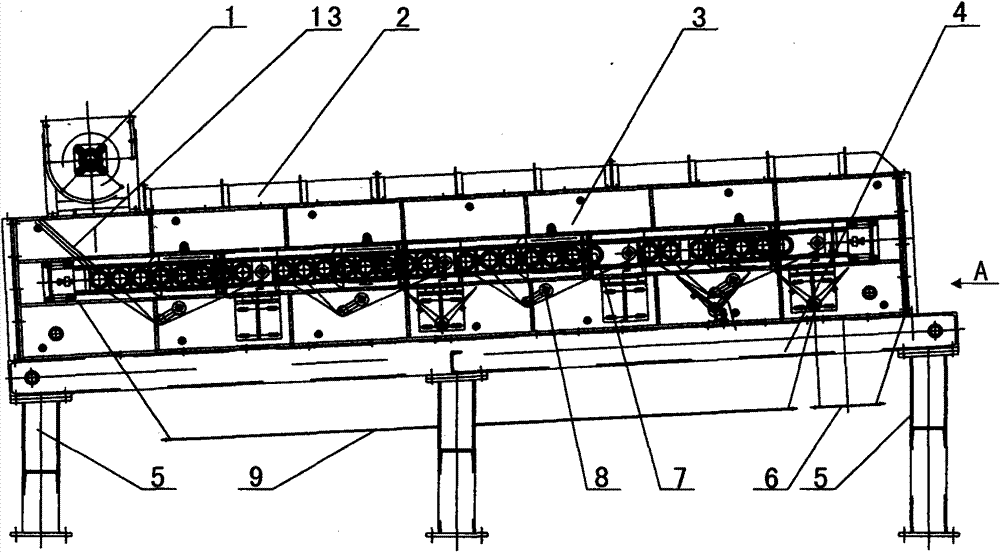

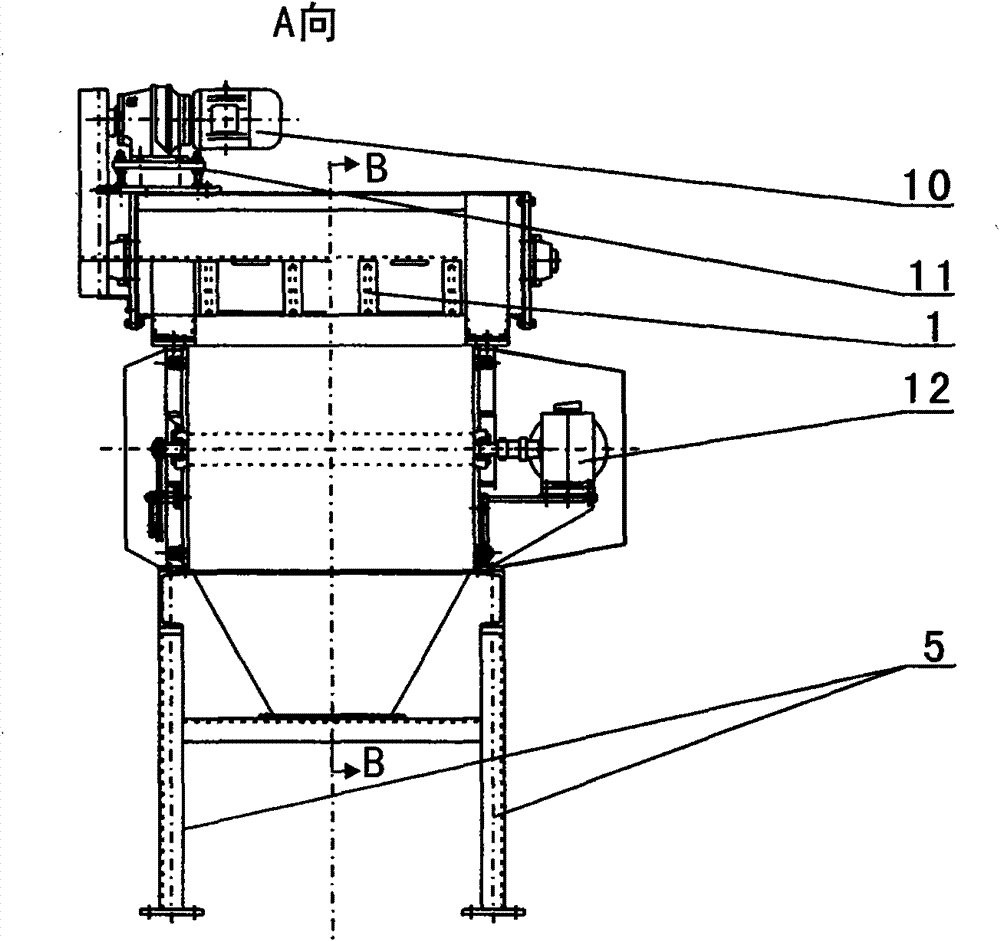

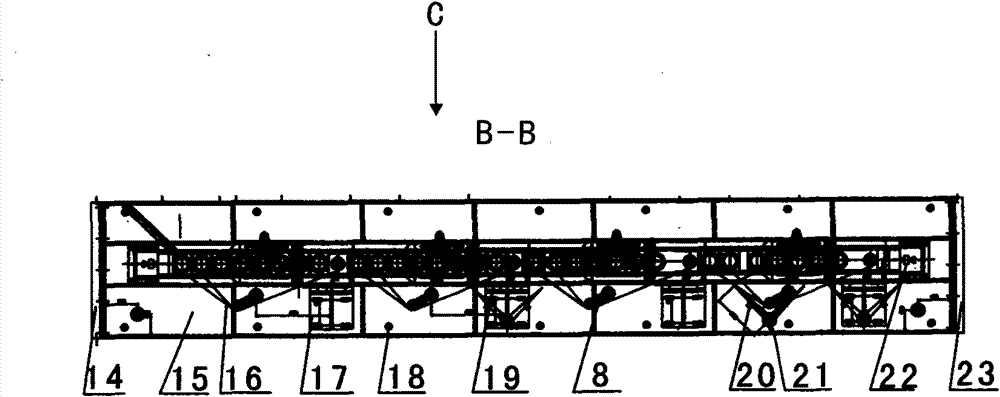

[0030] exist Figure 1-10 The rhomboid roller screening machine described in includes the feeding setting for the rhomboid roller; the rhomboid roller setting for sieving material sieving; due to the recovery mechanism after material sieving; the pair The feeding arrangement of the rhombus roller includes an upper reduction motor 10, a motor base A11, a material distribution screw 1 and a material guide plate 13. The motor base A11 of the upper reduction motor 10 is arranged on one side of the frame 4 top, and the upper reduction motor 10 The machine shaft is connected to one end of the material distribution screw 1, the material distribution screw 1 is arranged in the box body, and the upper part of the material distribution screw 1 is provided with a feed inlet, and the upper ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com