Method for preparing high-quality diesel oil by increasing cetane number through non-hydrodesulfurization

A cetane number, non-hydrogenation technology, which is applied in the field of non-hydrodesulfurization to increase the cetane number to prepare high-quality diesel oil, can solve the problems of low cetane number of diesel oil, small adjustment margin, and high operating costs. Achieve the effects of increasing cetane number, no hydrogen consumption, and easy handling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

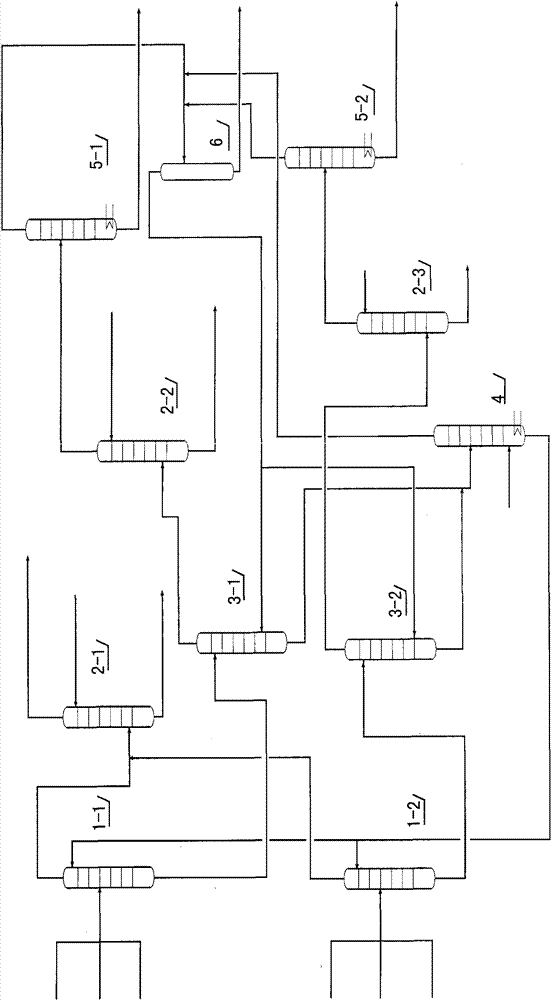

[0028] figure 1 It is a schematic flow diagram of this embodiment. Some auxiliary equipment such as separation tanks and pumps are not shown in the figure, but this is well known to those of ordinary skill in the art.

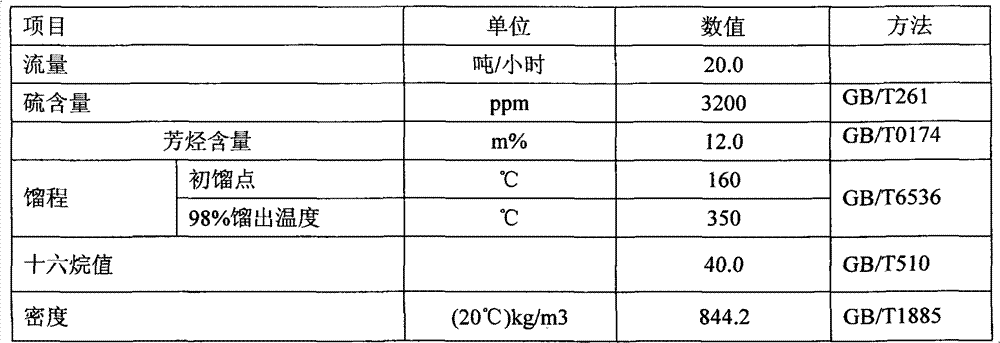

[0029] Such as figure 1 As shown, the distillation range is 160-350℃, the sulfur content is 3200ppm, and the density is 844.2kg / m 3 , The aromatic content is 12%, the cetane number is 40.0 light diesel (see Table 1-1 for raw material properties) and the solvent are added to the light diesel extraction tower at a flow rate of 20 tons / hour and 30 tons / hour respectively 1-1 for extraction. The temperature of the light diesel extraction tower 1-1 is 140°C, the pressure is 0.7 MPa, the solvent ratio is 2, the solvent used is sulfolane, the light raffinate oil is drawn at the top, and the light drawn oil is drawn at the bottom. The distillation range of the obtained light raffinate oil is 185-280℃, the sulfur content is 290ppm, and the density is 810.9kg / m 3 , The aro...

Embodiment 2

[0031] figure 1 It is a schematic flow diagram of this embodiment. Some auxiliary equipment such as separation tanks and pumps are not shown in the figure, but this is well known to those of ordinary skill in the art.

[0032] Such as figure 1 As shown, the distillation range is 163-351℃, the sulfur content is 4500ppm, and the density is 837.3kg / m 3 , The aromatic content is 15%, the cetane number is 39.6 light diesel (see Table 1-1 for raw material properties) and the solvent is added to the light diesel extraction tower at a flow rate of 25 tons / hour and a flow rate of 37.5 tons / hour respectively 1-1 for extraction. The temperature of the light diesel extraction tower 1-1 is 150°C, the pressure is 0.9 MPa, the solvent ratio is 3, the solvent used is sulfolane, the light raffinate oil is drawn at the top, and the light drawn oil is drawn at the bottom. The distillation range of the obtained light raffinate oil is 185-280℃, the sulfur content is 270ppm, and the density is 805.5...

Embodiment 3

[0034] figure 1 It is a schematic flow diagram of this embodiment. Some auxiliary equipment such as separation tanks and pumps are not shown in the figure, but this is well known to those of ordinary skill in the art.

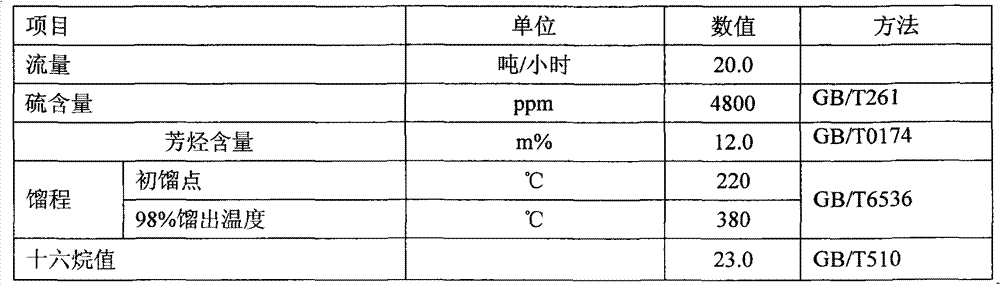

[0035] Such as figure 1 As shown, the distillation range is 188-303℃, the sulfur content is 5000ppm, and the density is 836.5kg / m 3 , The aromatic content is 18%, the cetane number is 40.5 light diesel (see Table 3-1 for raw material properties) and the solvent are added to the light diesel extraction tower at a flow rate of 30 tons / hour and a flow rate of 45 tons / hour respectively. 1-1 for extraction. The temperature of the light diesel extraction tower 1-1 is 160°C, the pressure is 1.1 MPa, the solvent ratio is 4, the solvent used is sulfolane, the light raffinate oil is drawn at the top and the light drawn oil is drawn at the bottom. The obtained light raffinate has a distillation range of 190-275°C, a sulfur content of 340ppm, and a density of 809.5kg / m 3 , ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com