System for producing diesel of high quality and method thereof

A high-quality diesel technology, applied in the petroleum industry, processing hydrocarbon oil, hydrotreating process, etc., can solve the problems of low cetane number of diesel oil, small adjustment margin, increased hydrogen consumption, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

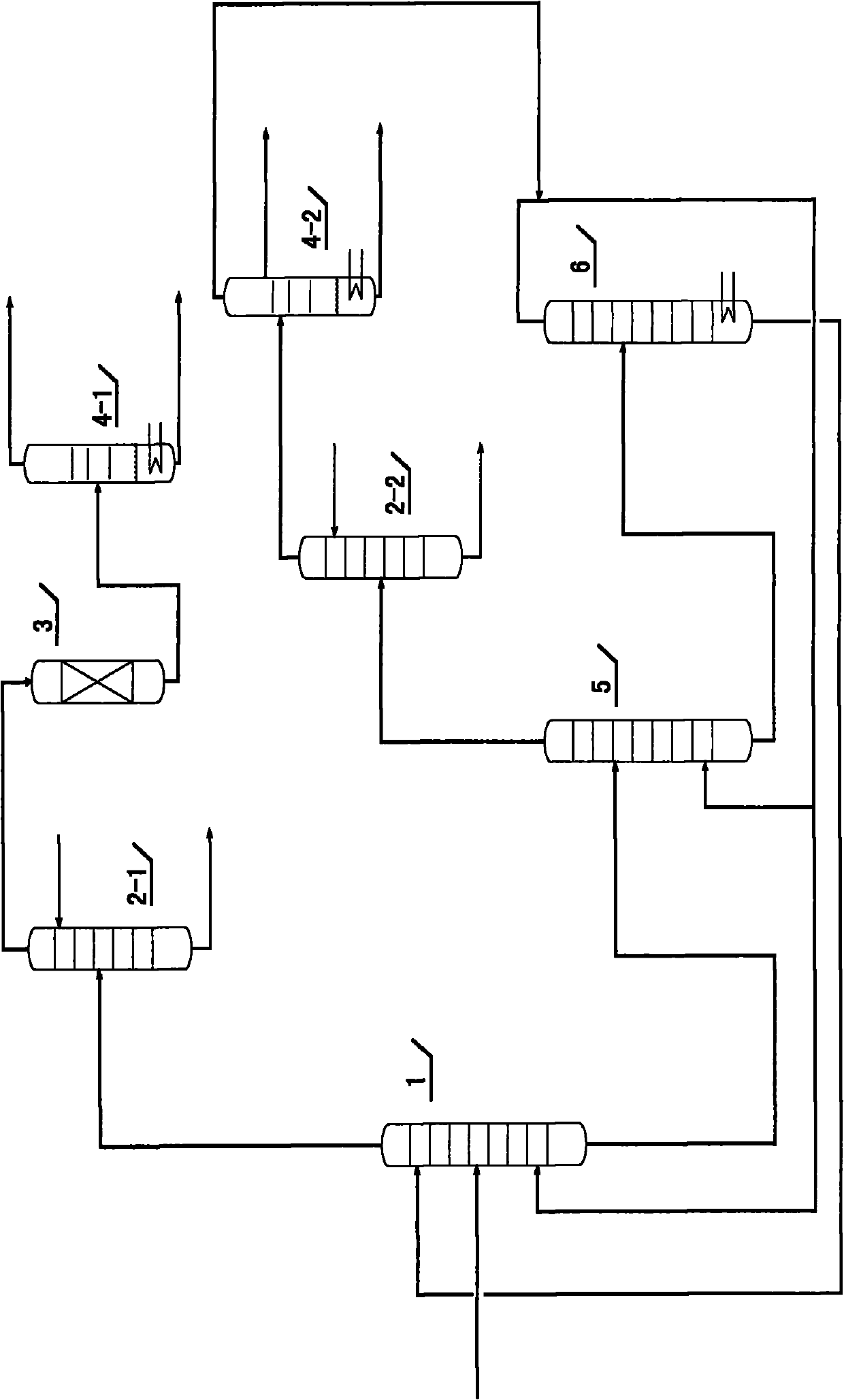

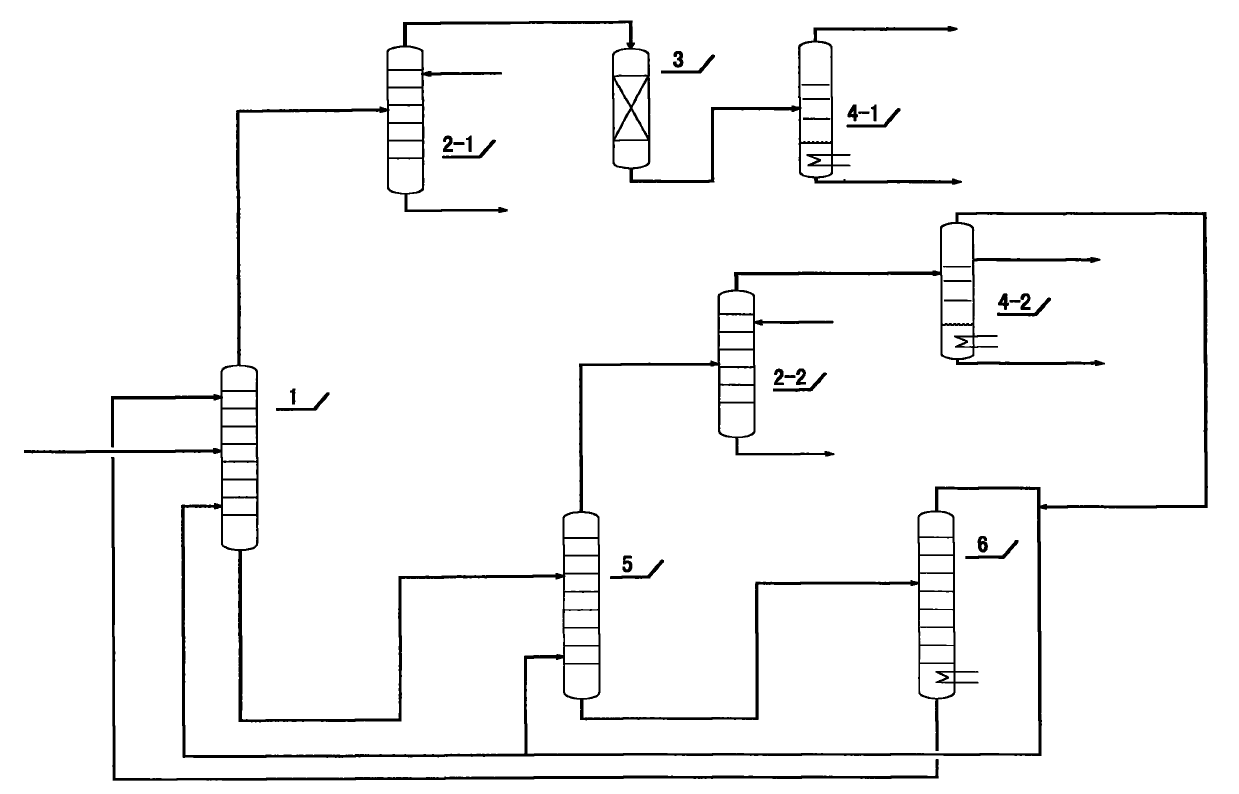

[0050] Such as figure 1 Shown is a schematic flow diagram of an embodiment of the present invention, and some auxiliary equipment such as tanks, pumps, heat exchangers, condensers, etc. are not marked in the figure, but this is well known to those of ordinary skill in the art.

[0051] Such as figure 1 As shown, the distillation range is 160-425 ° C, the sulfur content is 5000ppm, the density is 874.1kg / m3, the aromatics content is 29%, and the mixture of straight-run diesel oil and residual oil with a cetane number of 43 (the properties of the raw materials are shown in the table 1-1) The flow rate of 100 tons / hour and the solvent are added to the extraction tower 1 at a flow rate of 540 tons / hour for extraction. The temperature of the extraction tower 1 is 175 ° C, the pressure is 0.8 MPa, and the solvent ratio is 6. The solvent used is sulfolane, the obtained raffinate has a distillation range of 160-398°C, a sulfur content of 1333ppm, and a density of 853.2kg / m 3 , the c...

Embodiment 2

[0054] Such as figure 1 Shown is a schematic flow diagram of an embodiment of the present invention, and some auxiliary equipment such as tanks, pumps, heat exchangers, condensers, etc. are not marked in the figure, but this is well known to those of ordinary skill in the art.

[0055] Such as figure 1 As shown, the distillation range is 160-425°C, the sulfur content is 2000ppm, and the density is 879.2kg / m 3 , the aromatics content is 50%, the mixture of straight-run diesel oil and residual oil with a cetane number of 32 (see Table 1-2 for the properties of the raw material) is added together with a flow rate of 100 tons / hour and a solvent with a flow rate of 864 tons / hour. Extraction tower 1 carries out extraction, and the temperature of extraction tower 1 is 150 ℃, and pressure is 0.65MPa, and solvent ratio is 5, and solvent used is N-methylpyrrolidone, and the distillation range of gained raffinate is 160-399 ℃, sulfur The content is 667ppm, the density is 855.6kg / m 3 ,...

Embodiment 3

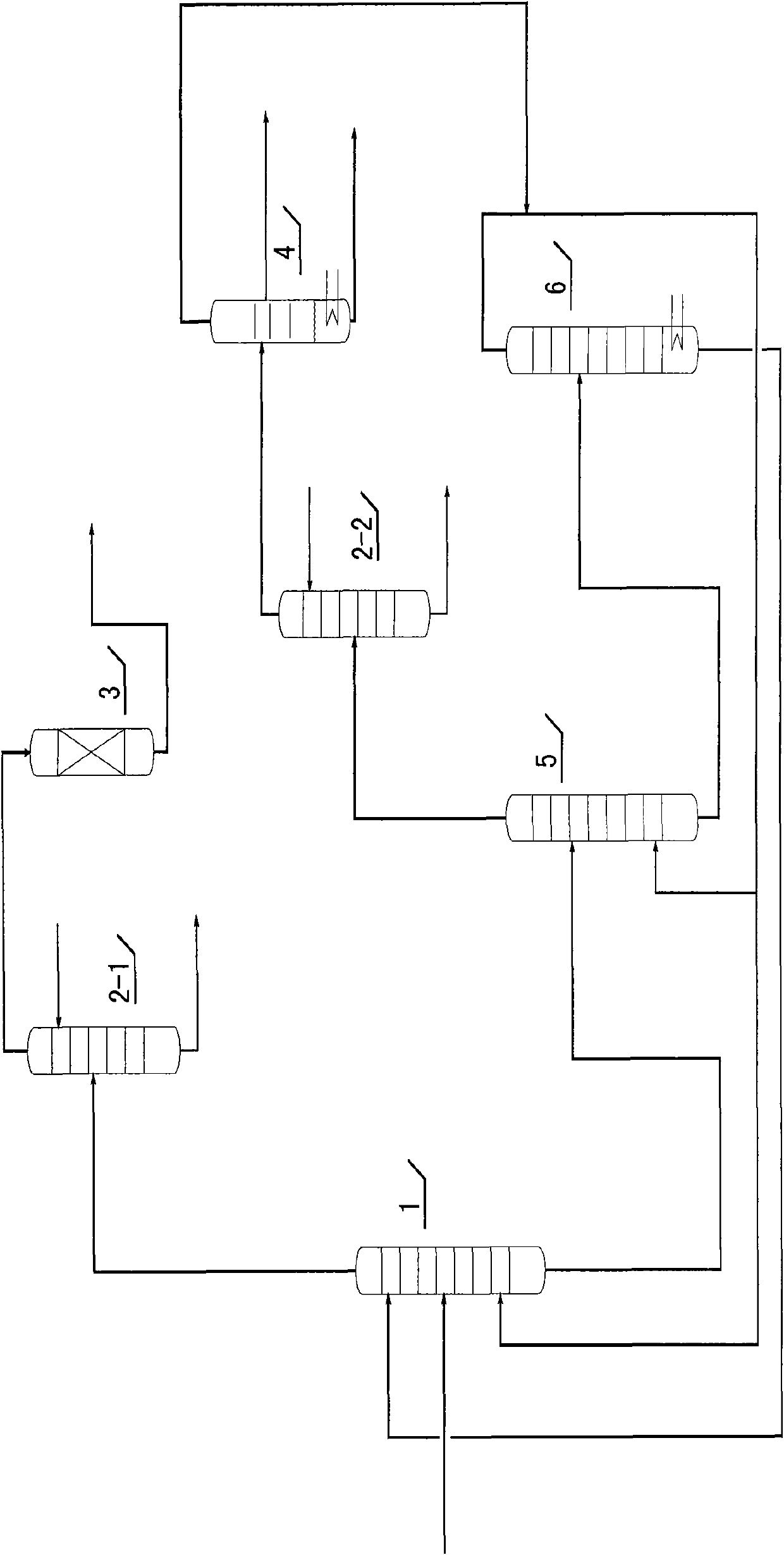

[0059] Such as figure 2 Shown is a schematic flow diagram of an embodiment of the present invention, and some auxiliary equipment such as tanks, pumps, heat exchangers, condensers, etc. are not marked in the figure, but this is well known to those of ordinary skill in the art.

[0060] Such as figure 2 As shown, the distillation range is 160-395°C, the sulfur content is 4000ppm, and the density is 857.6kg / m 3 , the aromatics content is 38%, the mixture of straight-run diesel oil and residual oil with a cetane number of 38 (see Table 1-3 for raw material properties) is added together with a flow rate of 100 tons / hour and a solvent with a flow rate of 600 tons / hour. Extraction tower 1 carries out extraction, and the temperature of extraction tower 1 is 90 ℃, and pressure is 0.5MPa, and solvent ratio is 2, and used solvent is dimethyl sulfoxide, and the distillation range of gained raffinate is 160-365 ℃, sulfur The content is 1000ppm, the density is 846.2kg / m 3, the content...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com