Lens grinding device for myopia correction glasses

A myopia correction and lens technology, which is applied in the direction of grinding drive device, grinding/polishing safety device, grinding machine, etc., can solve the problems of inconvenient operation, cumbersome, manual operation, etc., to reduce labor intensity, reduce manufacturing cost, and reduce pressure damage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

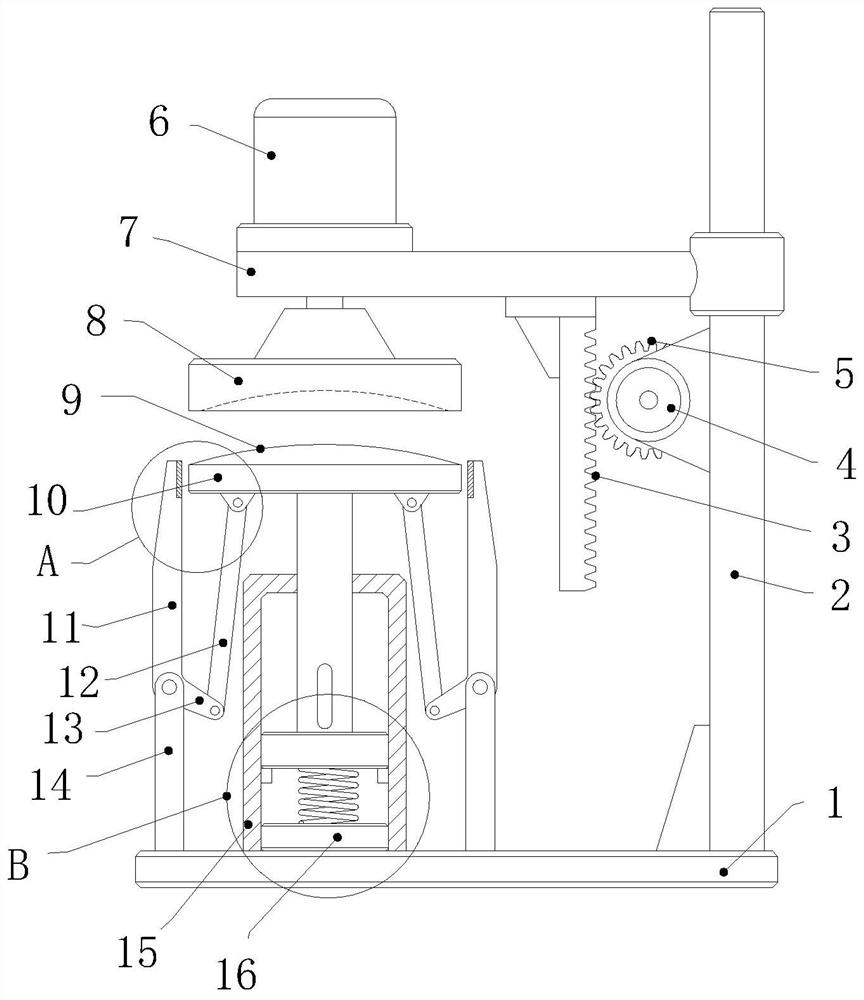

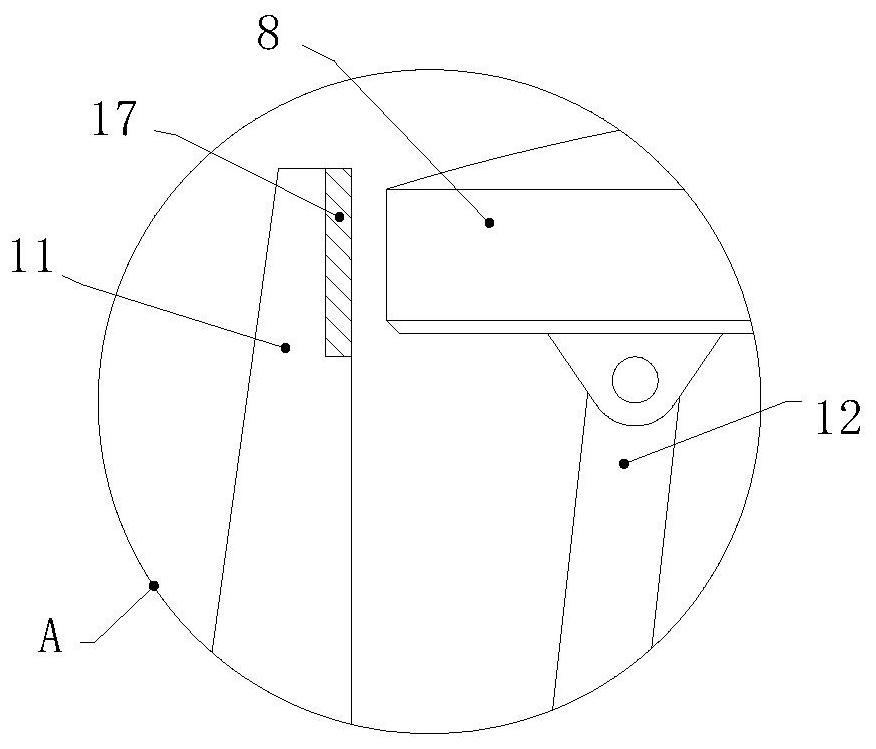

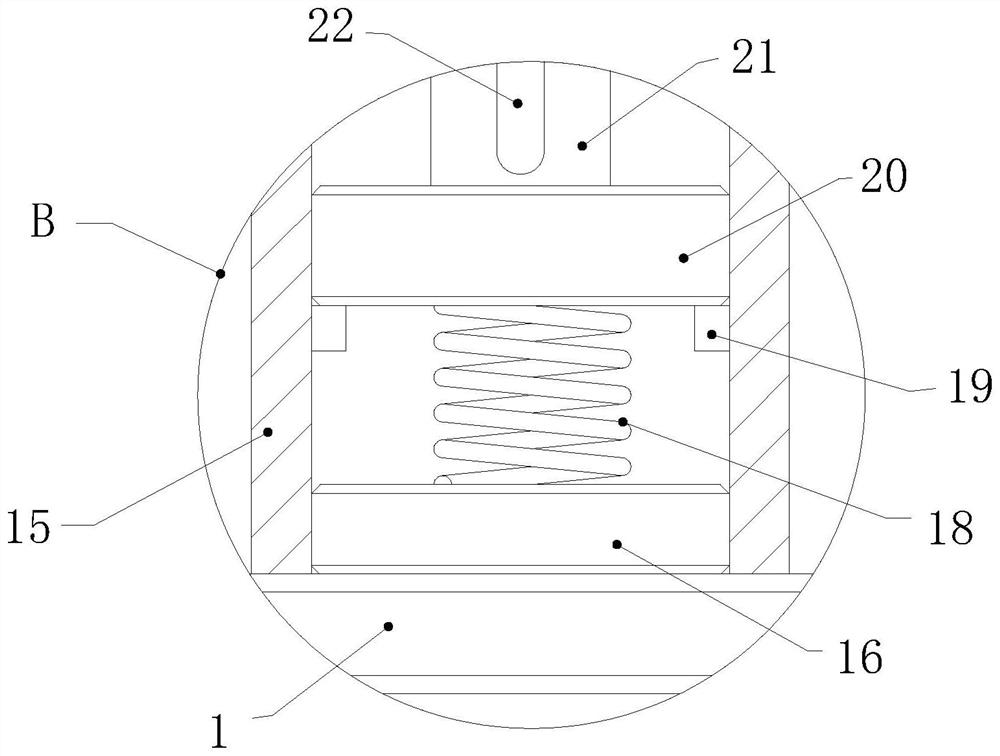

[0026] Such as Figure 1-5 As shown, the present embodiment provides a technical solution: a lens grinding device for myopia correction glasses, including a base 1, a grinding unit is provided on the base 1, a fixing seat 15 is provided on the base 1, and the fixing seat 15 is the same as The shaft is pierced with a connecting pipe 21, and the end of the connecting pipe 21 passing through the fixing seat 15 is provided with a suction head 10. The shape of the top of the suction head 10 is adapted to the contour of the lens, and there is a communication cavity connected with the connecting pipe 21 inside. 23. The top of the suction head 10 is provided with a plurality of air holes 24 communicating with the communicating cavity 23, the end of the connecting pipe 21 penetrating into the fixed seat 15 is provided with a sliding plug 20, and the connecting pipe 21 is provided with a sliding plug 20 on the outer wall adjacent to the end of the sliding plug 20. There is a ventilating...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com