Debugging platform for chemical process

A platform and process technology, applied in the direction of program control, comprehensive factory control, electrical program control, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

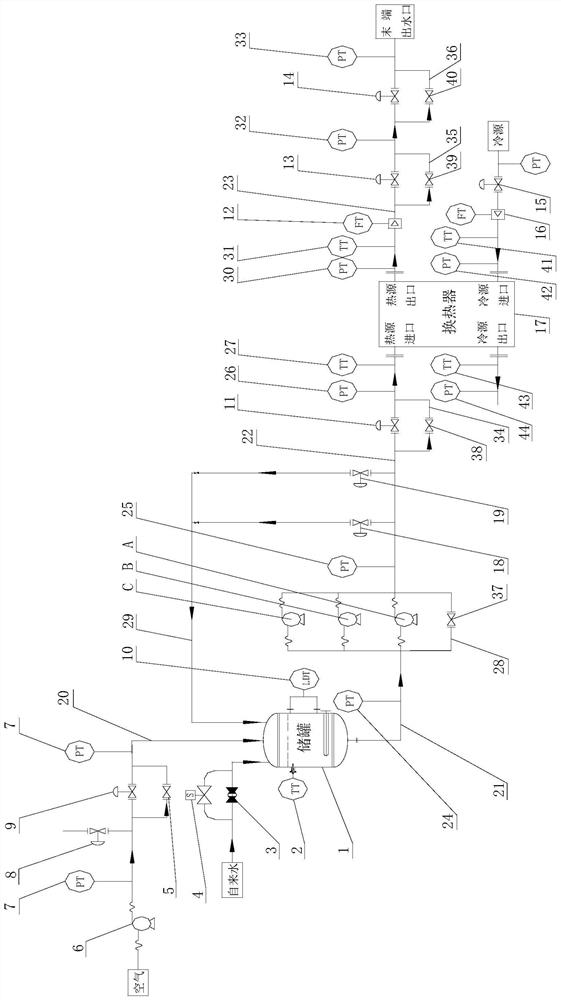

[0016] A commissioning platform for the chemical process, the principle of the mainstream system flow system figure 1 Indicated. The platform includes a air compressor 6 as a power source, a water storage tank 1, and a pump, and a heat exchanger 17 and a control system, and the air holding port of the air compressor 6 communicates with the air intake of the water tank 1, in the trachea 20 The serial air flow regulating valve 9 and the bypass air pressure regulating valve 8 are provided, and two air pressure transmitter 7 are provided on the front and rear air pipe 20 of the airflow regulator valve 9 and and the bypass air pressure regulating valve 8. The water storage tank 1 is provided with water inlet, water outlet and returns, and the water storage tank 1 is connected to water, and the water supply valve 3 and the program-controlled hydrating valve 4 are provided on the water supply pipe. The pump contains three pumps in parallel, respectively, and fixed frequency centrifugal p...

Embodiment 2

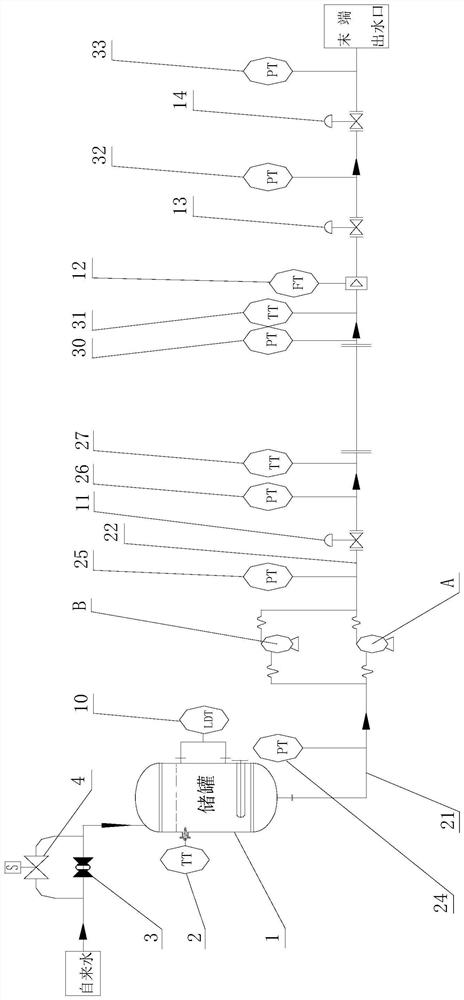

[0030] This example is a first case of a debug platform for the chemical flow of the chemical flow, which is the main research object in the inlet dielectric pressure and flow of heat exchanger 17. Closing the converter plunger pump C and the first shutoff valve 37 by cutting the air input branch (including the air compressor 6, the air flow regulating valve 9, the bypass air pressure regulating valve 8, and the air pipe 20) (cutting the first water flow bypass tube) 28), turn off the water flow bypass pressure regulating valve 18 and the water flow bypass flow regulating valve 19 (cutting the second water flow bypass pipe 29), close the second shutoff valve 38 (cutting the third water flow bypass pipe 34), will heat transfer The first inlet (heat source inlet) of the device 17 and the first outlet (heat source outlet) are directly connected to the third cutoff valve 39 (cutting the fourth water flow bypass 35) and the fourth shut-off valve 40 (cutting off the fifth water flow byp...

Embodiment 3

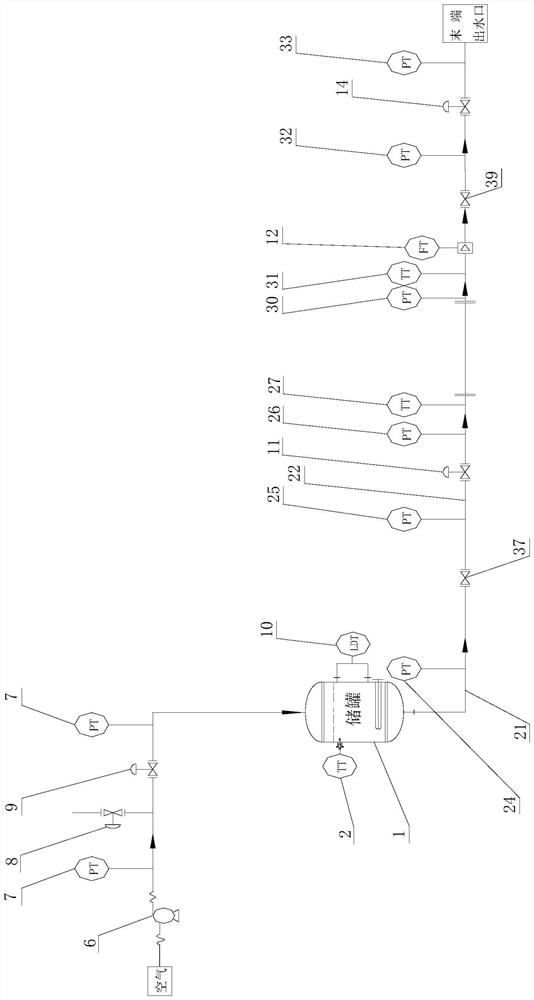

[0037] This embodiment is a second case of a commissioning platform for the chemical flow of the chemical flow, which is studied in the state of the storage tank 1 and the atmosphere, and the water in the storage tank 1 is self-gravity. Under the action, real-time adjustment and collection of water flow by water flow pressure valve 11 and the first flow meter 12. The second case-composed of the second seed debug platform is close to the first seed debug platform of the second embodiment, and the flow chart is image 3 Indicated (by figure 1 Equivalently), the second seed debug platform is different from the same as the first seed debug platform in Example 2:

[0038] 1) Cut the self-reciprocating input branch (including the manual hydrating valve 3 and the transpsole valve 4 thereof on the water pipe) to open the air input branch (including air compressor 6, air flow regulating valve 9, air pressure regulating valve 8 and trachea) 20).

[0039] 2) Turn off the three pumps in parall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com