Automatic stub threading equipment for copper clip buttons

A technology of automatic threading and sewing, applied in the direction of sewing tools and other directions, can solve the problems of low processing efficiency, waste of labor costs, slow speed, etc., and achieve the effect of saving production costs and improving production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] This embodiment is a preferred implementation mode of the present invention, and other principles and basic structures that are the same or similar to this embodiment are within the protection scope of the present invention.

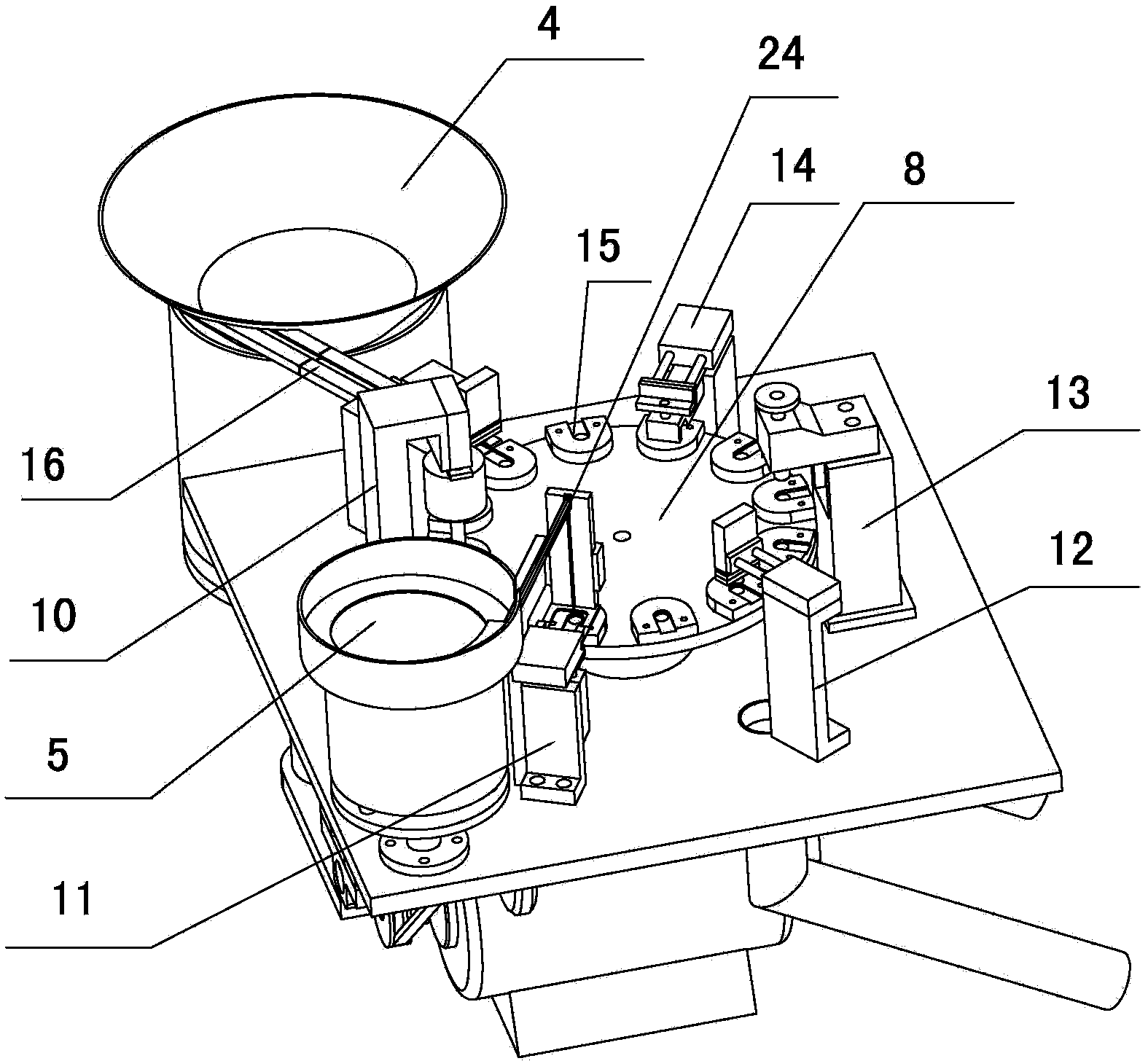

[0032] Please see attached figure 1 to attach Figure 4 , the present invention mainly includes a chassis 1, an electric control box 2, a working platform (not shown in the figure), a button vibrating plate 4, a thread foot vibrating plate 5, a turntable 8, a button feeding device 9, a button direction adjusting device 10, and a thread foot The material device 11, the line foot detection device 12, the pressing device 13 and the material return device 14, the inside of the cabinet 1 is a frame 3, the electric control box 2 is installed on the cabinet 1, the working platform is installed on the top of the cabinet 1, and the turntable 8 is installed on the working On the platform, a button feeding device 9, a button direction adjusting device 10, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com