Method for preparing cannabidiol

A technology for secondary cannabidiol and primary cannabidiol, which is applied in the field of preparation of secondary cannabidiol, can solve problems such as hidden dangers, difficult industrialization of pretreatment, existence of yield and pigment, etc., and achieves less impurities and good prospects for industrialized preparation , the effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

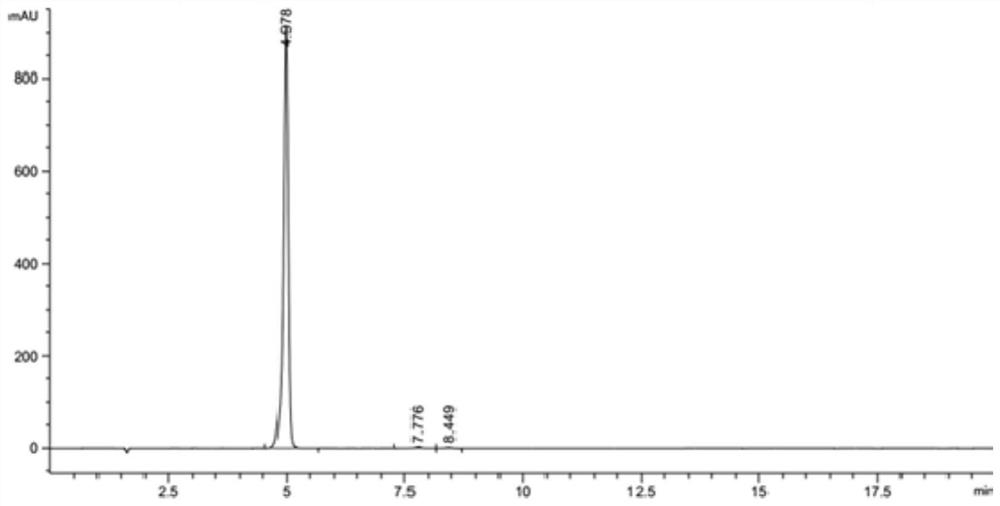

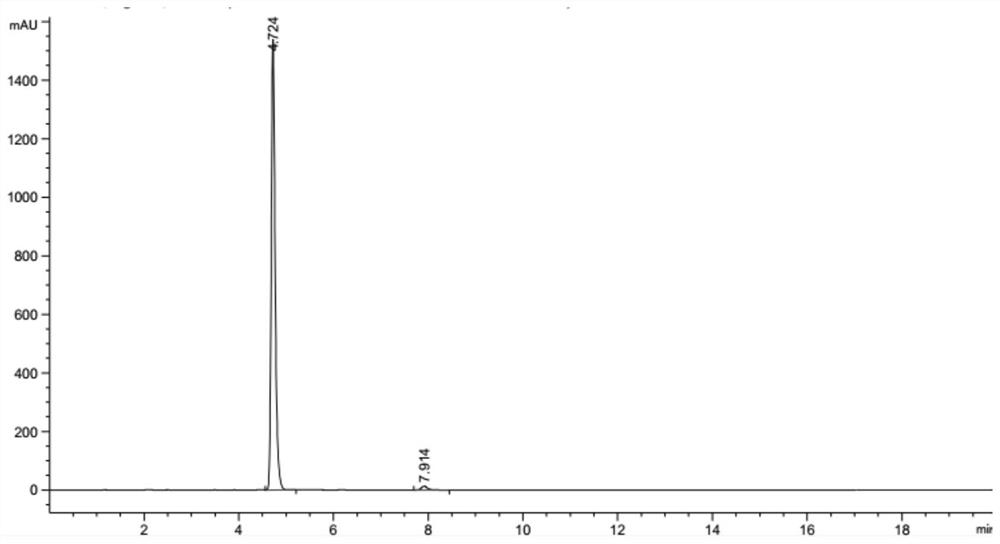

[0093] Preparation of the reference substance solution: Accurately weigh the CBDV reference substance, add methanol-water (1:1, V / V) to make a reference substance solution containing 0.1 mg per 1 ml, and obtain the solution.

[0094] Preparation of CBDV test solution: Take about 25mg of CBDV finished product, accurately weigh it, put it in a 250ml measuring bottle, add 20ml of acetonitrile-water (1:1, V / V), sonicate for 10 minutes, add acetonitrile-water (1 :1, V / V) diluted to the mark, shake well, filter through a microporous membrane (0.45pm), take the subsequent filtrate, and obtain.

[0095] Preparation of industrial hemp mosaic leaf raw material for the test solution: accurately weigh and pulverize to 500 mg of mosaic leaf fine powder of 75-150 microns, put in a 50ml conical flask, add 50ml of 75% methanol solution (Vol%) precisely, weigh, and ultrasonically 20 minutes, ultrasonic frequency 40KHZ, stand still for 30 minutes, weigh again, make up for the lost weight with 7...

Embodiment 1

[0103] Embodiment 1 prepares CBDV according to the following method

[0104] 1) Grinding the industrial hemp mosaic raw material into a 10-mesh coarse powder, with a moisture content of 14.6 wt%, to obtain a pretreated material;

[0105] 2) Soak 100kg of the above-mentioned pretreated materials in 5 times volume (W / V, 1Kg corresponds to 5L) of 60wt% ethanol aqueous solution at room temperature for 1 hour each time, extract 3 times, and combine to obtain the extract;

[0106] 3) Concentrate the above extract at 50°C, -0.10Mpa until it has no alcohol smell, and the relative density is 1.05, add purified water with a pretreatment amount of 1 / 100 (w / w), heat up to 110°C in an oil bath for 1 hour, and then , into 110 ° C steam, normal pressure decoction to remove residual water, to obtain dry extract.

[0107] 4) Weigh the above dry extract, add 4 times the amount (W / W) of diatomaceous earth and calcium phosphate (mass ratio 3:1), mix well to make a solid dispersion, and transfer ...

Embodiment 2

[0111] Example 2 Prepare CBDV according to the following method

[0112] 1) Grinding the industrial hemp mosaic raw material into 40-mesh powder, the moisture content value is 13.5wt%, to obtain the pretreated material;

[0113] 2) A total of 100 kg of the above-mentioned pretreated materials were soaked in 7 times the volume (W / V) of 75% ethanol (Vol%) at room temperature for 2 hours, extracted twice, and combined to obtain the extract;

[0114] 3) Concentrate the above extract at 60°C, -0.080Mpa until there is no alcohol smell, and the relative density is 1.15, add purified water with a pretreatment amount of 1 / 10 (w / w), boil at normal pressure (94°C) for 2 hours, Subsequently, at 65°C, the remaining water was evaporated under reduced pressure at -0.095Mpa to obtain a dry extract.

[0115] 4) Weigh the above dry extract, add 0.25 times the amount (W / W) of silica gel, mix well to make a solid dispersion, transfer to a chunky extraction column (d:L=1:2), and use n-heptane : ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com