Method for finely controlling mechanical property of NiAl-based composite material through particle size ofpowder

A technology of fine control and composite materials, applied in transportation and packaging, metal processing equipment, etc., can solve the problems of difficult fine control of grain size, difficult coordination of room temperature toughness and high temperature strength, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

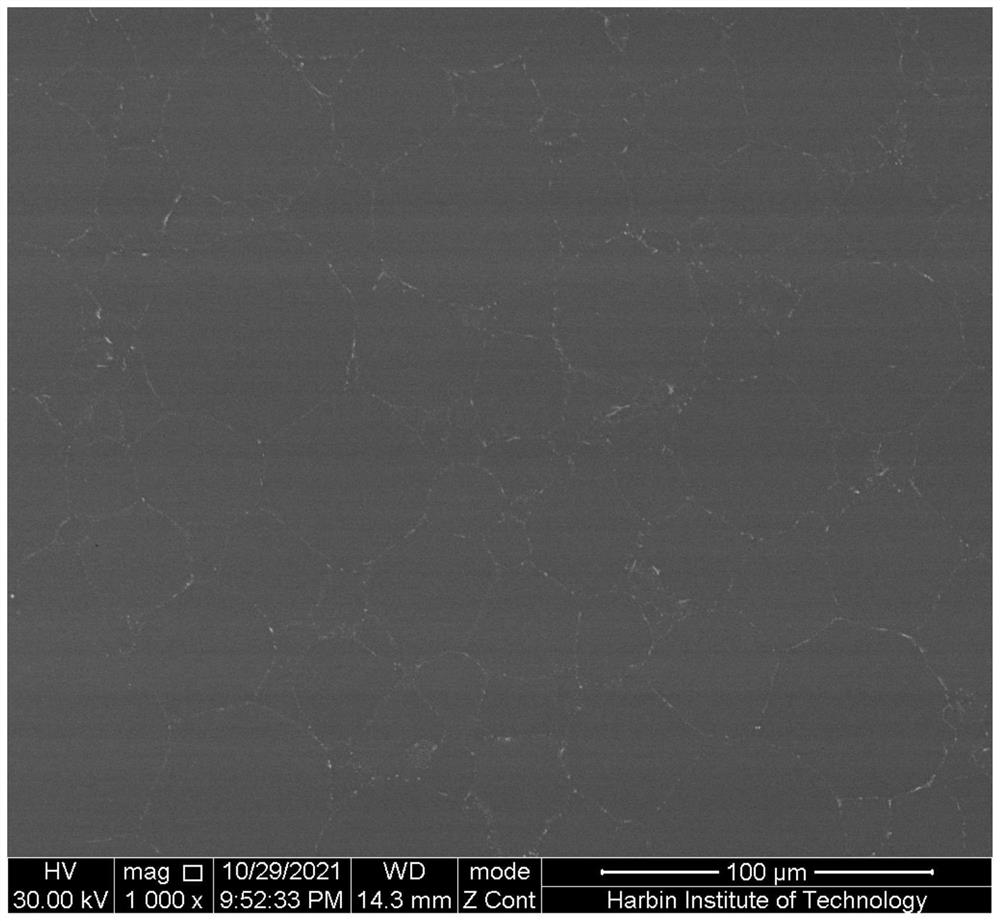

[0041] Specific Embodiment 1: In this embodiment, a method for finely controlling the mechanical properties of NiAl-based composite materials through powder particle size is completed in the following steps:

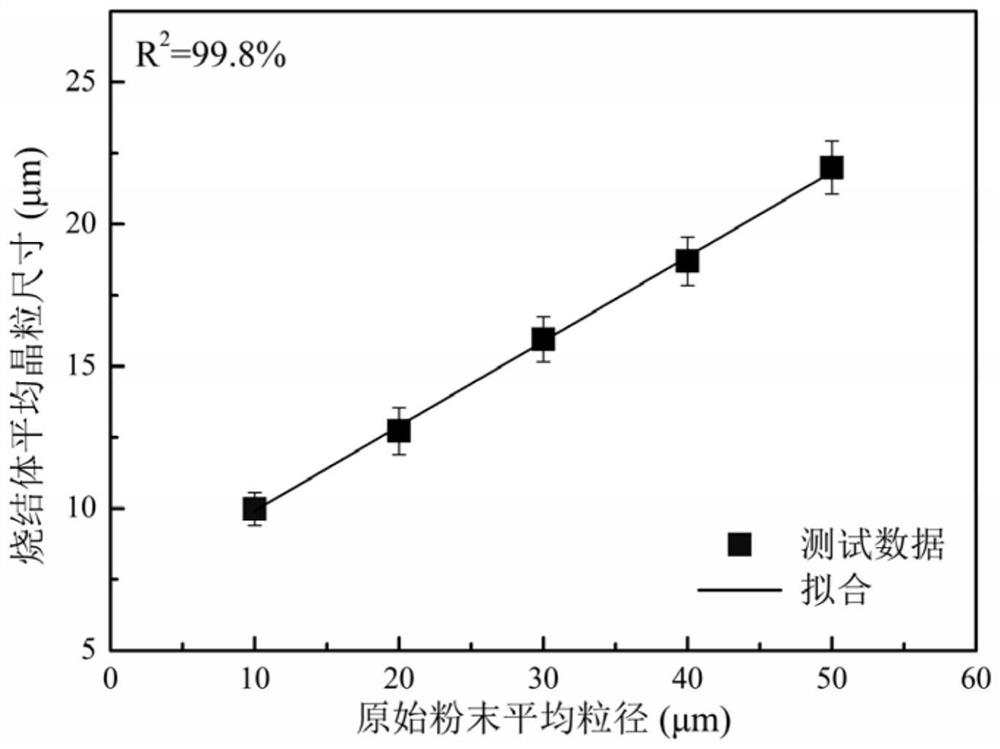

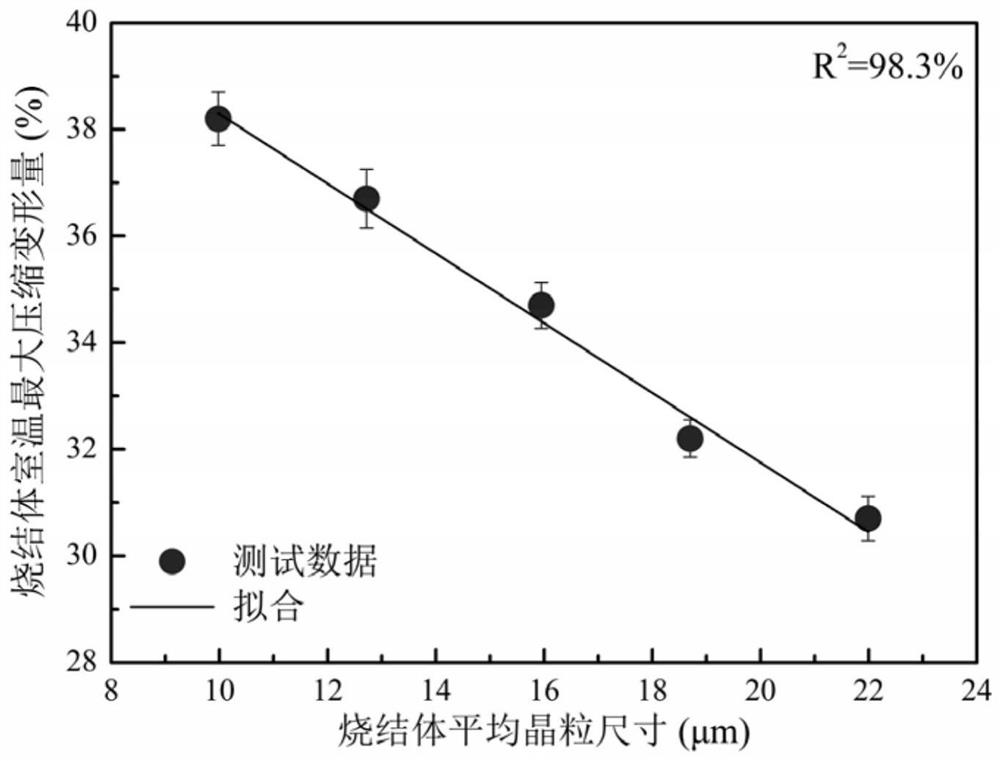

[0042] 1. Sieve the NiAl-based composite material alloy powder into 5 groups of raw powders with different average particle sizes;

[0043] The average particle diameters of the five groups of primary powders in step 1 are 10 μm, 20 μm, 30 μm, 40 μm and 50 μm, respectively;

[0044] 2. Put 5 groups of raw powders with different average particle sizes into 5 mixing buckets respectively, and fill the 5 mixing buckets with O 2 , and then put 5 powder mixing buckets on the roller ball mill to mix powder, and get 5 groups of surfaces fully adhered to O 2 alloy powder;

[0045] 3. Transfer 5 groups of alloy powders into 5 moulds, respectively apply pressure and maintain pressure, and then put 5 moulds into spark plasma sintering furnaces respectively;

[0046] 4. Conduct el...

specific Embodiment approach 2

[0067] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the preparation method of the NiAl-based composite material alloy powder described in step 1 is as follows:

[0068] 1. Weigh metal Ni particles, Al particles and Hf particles, mix them evenly, and then vacuum refine them twice at a temperature of 1500°C, each vacuum refining time is 5 minutes, to obtain a liquid alloy;

[0069] 2. Transfer the liquid alloy into a cylindrical mold for cooling to obtain a cylindrical cast alloy;

[0070] 3. The cylindrical cast alloy is prepared into NiAl-based composite material alloy powder by argon atomization method. Other steps are the same as in the first embodiment.

specific Embodiment approach 3

[0071] Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that the purity of the metal Ni particles, Al particles and Hf particles described in step 1 is greater than 99.5%. Other steps are the same as those in Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com