Method for improving fluorescence efficiency of zero-dimensional perovskite material

A perovskite material and fluorescence technology, which is applied in the direction of luminescent materials, chemical instruments and methods, etc., can solve the problems of affecting spectral analysis, limiting applications, and long time consumption, and achieve the effect of improving fluorescence efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

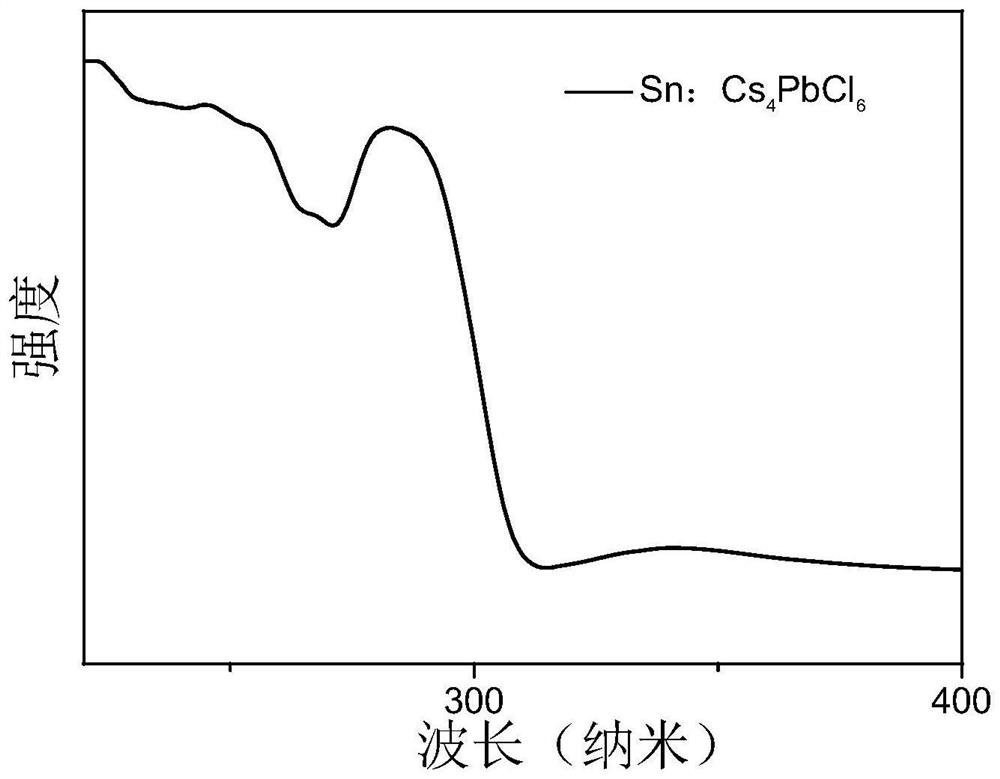

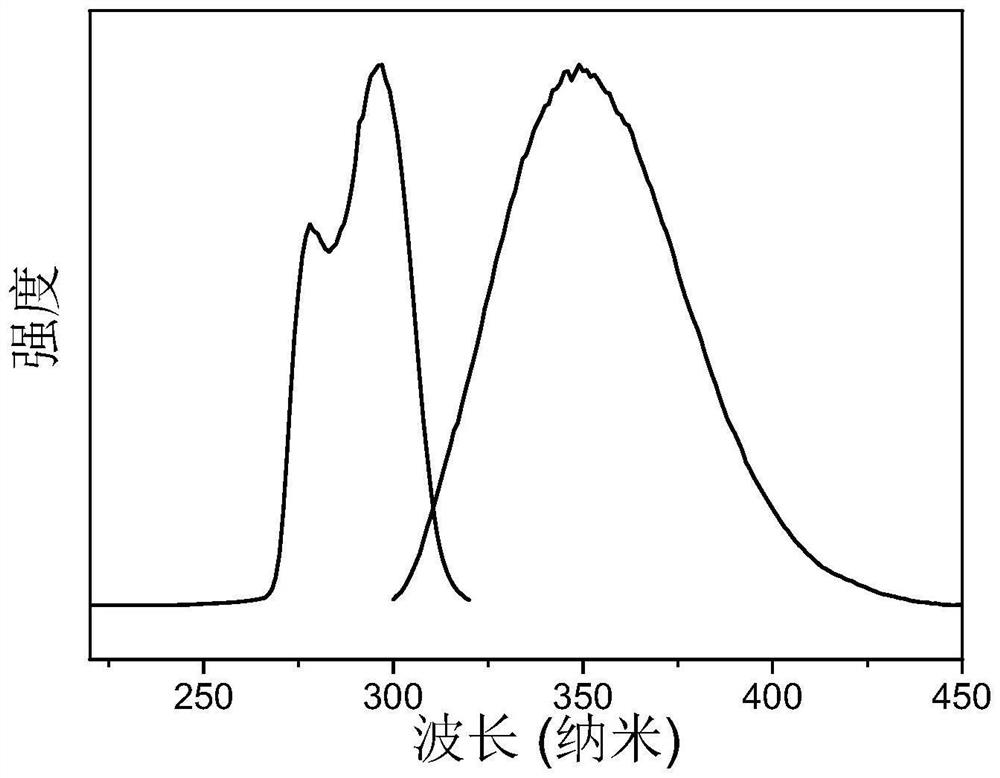

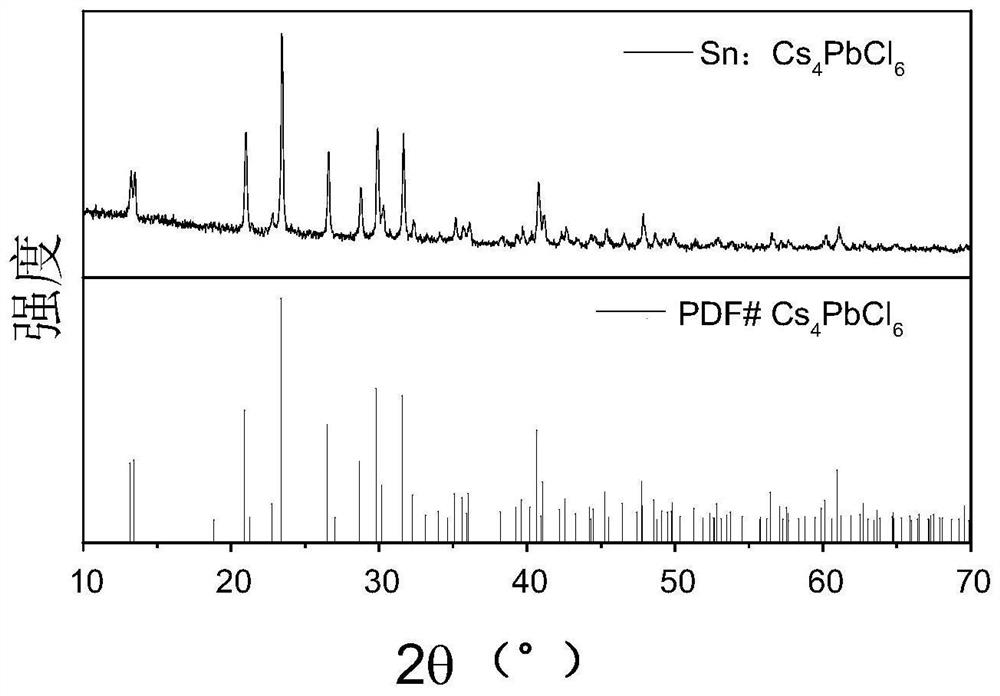

[0020] Weigh 4mmol cesium chloride and 1mmol lead chloride in the glove box, pour them into a 25mL agate jar containing 25 agate balls with a diameter of 6mm, seal the agate jar with a sealing film, and take it out of the glove box , set the AC frequency of the ball mill to 40Hz, and mechanically grind for 5 hours. The white mixture powder will change from fluffy to dense with the prolongation of the grinding time, and finally turn into fluffy white powder. Stop grinding. At this time, irradiate with an ultraviolet lamp with an excitation wavelength of 302nm , the product is not fluorescent. Put the obtained product into a hydrothermal reaction kettle, add 0.2mol stannous chloride, 150 microliters of hypophosphorous acid, 5 milliliters of hydrochloric acid, 0.1mmol of sodium citrate, maintain at 180°C for 600min to ensure that the precursor is completely dissolved, pass 10°C / h Slowly cool down to room temperature. After annealing at room temperature, the obtained crystals we...

Embodiment 2

[0024] In Example 1, since Sn 2+ Instability, it is very easy to generate oxidation reaction to form Sn in high temperature acidic solution 4+ , has an adverse effect on the fluorescence quantum yield of the product, so hypophosphorous acid must be added. Now change the amount of hypophosphorous acid from 150 μL in Example 1 to 100 μL, 200 μL, and 300 μL, and keep other conditions and steps unchanged. 150 μL is optimal.

Embodiment 3

[0026] The amount of hydrochloric acid in Example 1 was changed from 5mL to 3mL, 4mL, and 6mL respectively, and other conditions and steps were unchanged. The fluorescence efficiencies of each product were measured to be 79.6%, 71.4%, and 78.3%, respectively, so the amount of hydrochloric acid was 5mL. excellent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com