Self emission type photosensitive resin composition, color filter comprising color conversion layer using same, and image display device

A photosensitive resin, self-luminous technology, applied in luminescent materials, chemical instruments and methods, photosensitive materials used in optomechanical equipment, etc., can solve the problems of reduced brightness, difficult to expect light efficiency, etc., and achieve the effect of improving fluorescence efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

manufacture example 1

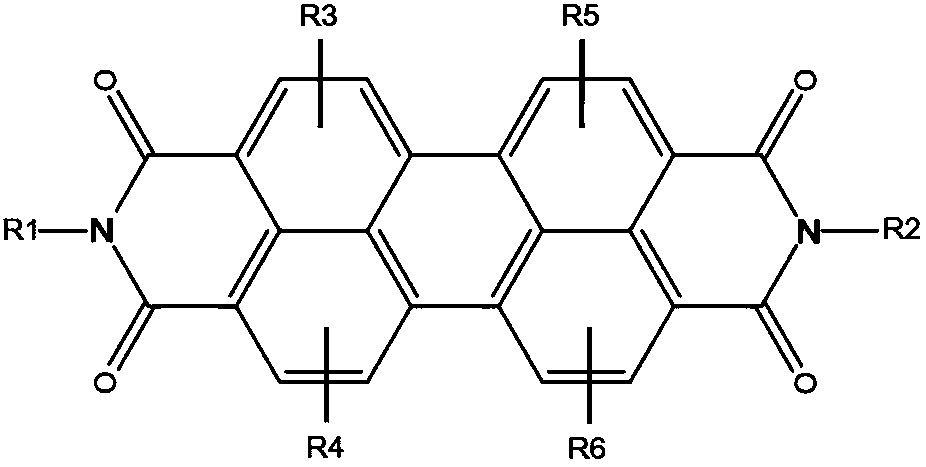

[0157] Production Example 1: Synthesis of Intermediate Compound (INT)

[0158]

[0159] Put 1,6,7,12-tetrachloroperylenetetracarboxylic dianhydride (0.11mol) and 2,6-diisopropylaniline (0.44mol) into 1L of propionic acid, raise the temperature, and maintain the reaction at 140°C for 5 hours. The reaction solution was cooled to room temperature, and the precipitate was filtered under reduced pressure and washed with methanol water. The filtrate was dispersed in water, kept for 30 minutes, then filtered under reduced pressure, dispersed in methanol again, kept for 30 minutes, and then filtered under reduced pressure. After drying, an intermediate compound (INT) was obtained in a yield of 80.5%.

[0160] The MS (mass spectrum) of the obtained intermediate compound was measured using a MALDI-TOF measuring device. As a result, it was confirmed that the molecular weight was 848.16.

Synthetic example 1

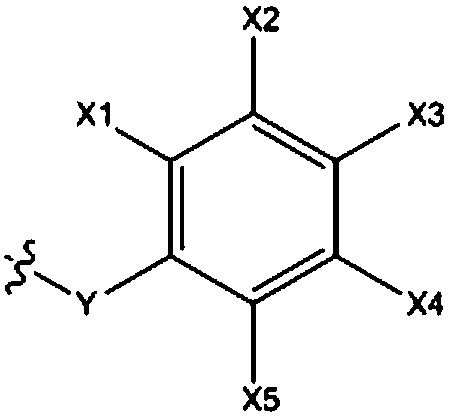

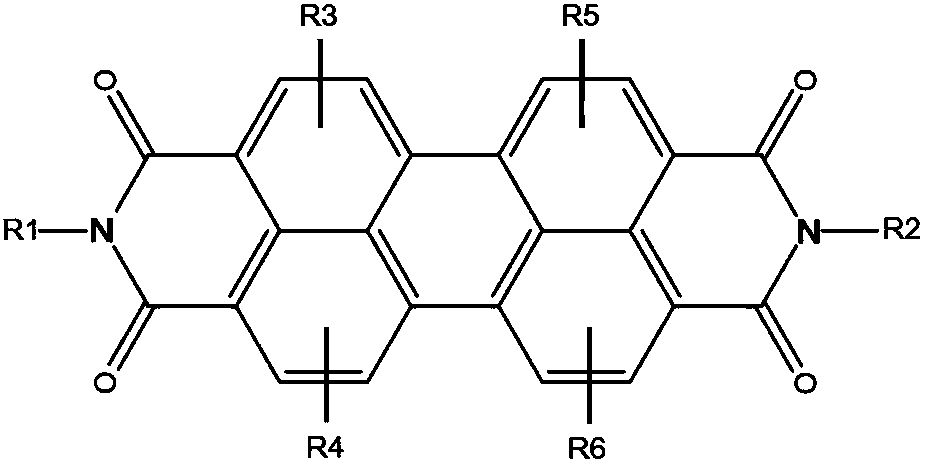

[0161] Synthesis Example 1: Manufacture of a compound represented by Chemical Formula 3-1

[0162]

[0163] After adding potassium carbonate (0.04 mol) to the solution of INT (0.04 mol) and N-methylpyrrolidone (266.1 g) produced in Production Example 1 above, the temperature was raised to 120°C. A liquid obtained by dissolving 4-fluorophenol (0.04 mol) in N-methylpyrrolidone (88.7 g) was added to the reaction liquid at 120° C. over 2 hours. After maintaining the reaction at the same temperature for 1 hour, 4-chlorophenol (0.16 mol) and potassium carbonate (0.16 mol) were added, and stirring was performed over 4 hours. The reaction liquid was cooled to room temperature, and discharged into 3 L of distilled water. The resulting red-purple precipitate was filtered under reduced pressure and washed with methanol water. The filtrate was redissolved in dichloromethane (MC), filtered through silica to remove impurities, and recrystallized with MeOH to obtain the compound represe...

Synthetic example 2

[0165] Synthesis Example 2: Manufacture of Compounds Represented by Chemical Formula 3-3

[0166]

[0167]After adding potassium carbonate (0.04 mol) to the solution of INT (0.04 mol) and N-methylpyrrolidone (266.1 g) produced in Production Example 1 above, the temperature was raised to 120°C. A liquid obtained by dissolving 2,4-di(tert-butyl)phenol (0.04 mol) in N-methylpyrrolidone (88.7 g) was added to the above reaction liquid at 120° C. over 2 hours. After maintaining the reaction at the same temperature for 1 hour, 4-chlorophenol (0.16 mol) and potassium carbonate (0.16 mol) were added, and stirring was performed over 4 hours. The reaction solution was cooled to room temperature, and discharged into 3 L of distilled water. The resulting red-purple precipitate was filtered under reduced pressure and washed with methanol water. The filtrate was redissolved in methylene chloride (MC), filtered through silica to remove impurities, and recrystallized with MeOH to obtain t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com