A kind of preparation method of insulating paint with heat transfer function

A functional insulation and spherical technology, applied in the direction of coating, etc., can solve the problems that cannot meet the requirements of heat conduction in electrical insulation occasions, and achieve simple and practical effects of controllable paint film thickness, high fluidity, and poor thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to be able to clearly and completely understand the technical solution, the present invention will now be further described with reference to the embodiments and the accompanying drawings. Obviously, the described embodiments are only some of the embodiments of the present invention, and those skilled in the art will not make creative work under the premise of All other embodiments obtained belong to the protection scope of the present invention.

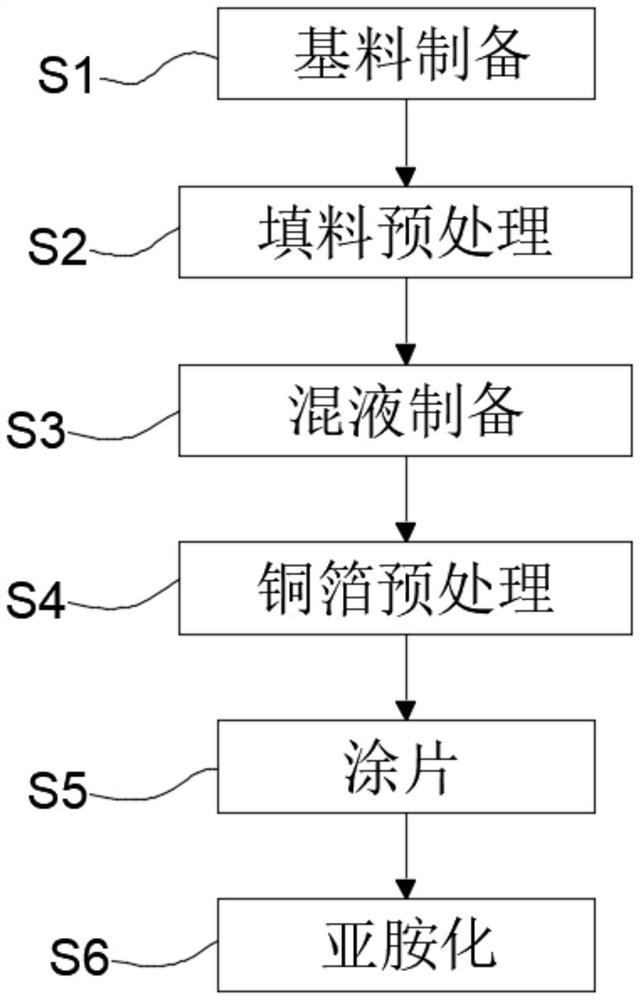

[0032] like figure 1 As shown, a preparation method of insulating paint with heat transfer function comprises the following steps:

[0033] Preparation of S1 base material: take equal amounts of N,N-dimethylacetamide and 4,4-diaminodiphenyl ether with a purity of more than 99%, stir until they are completely dissolved, and then add 99% purity of pyromellitic tetrakis Formic dianhydride, stirring until a viscous, pale yellow homogeneous solution is obtained;

[0034] S2 filler pretreatment: first add absolute ethano...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com