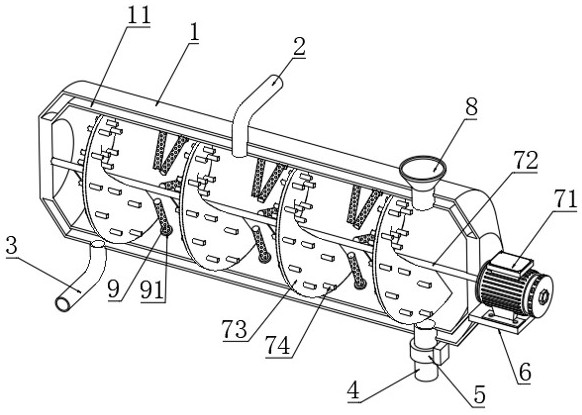

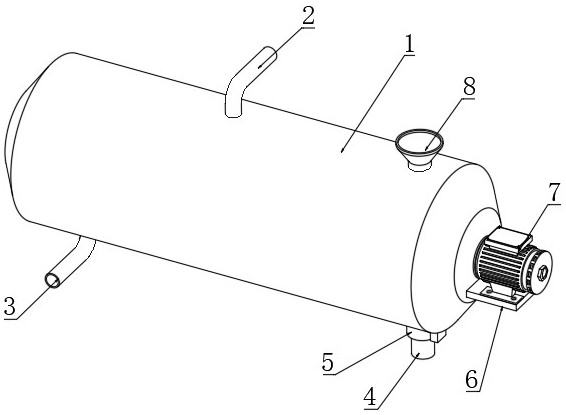

Water-based environment-friendly anti-corrosive paint and production equipment thereof

A technology for anti-corrosion coatings and production equipment, used in anti-corrosion coatings, epoxy resin coatings, anti-fouling/underwater coatings, etc. Corrosion effect, good antibacterial ability, effect of improving stirring efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] The water-based environmentally friendly anti-corrosion coating is formed by mixing component A and component B through stirring equipment:

[0037] The component A is composed of the following components in parts by weight: 25 parts of epoxy resin, 10 parts of dibutyl phthalate, 5 parts of acrylic acid emulsion, 8 parts of garlic extract, 8 parts of marigold extract, dispersion 2 parts of agent, 3 parts of emulsifier, 8 parts of anti-rust pigment, 10 parts of deionized water;

[0038] The component B is composed of the following components in parts by weight: 3 parts of silicon dioxide powder, 2 parts of copper powder, and 2 parts of kaolin.

[0039] The preparation method of the water-based environmental protection anti-corrosion coating is as follows: each raw material in the above-mentioned component A and component B is fully stirred and mixed through the production equipment of the water-based environmental protection anti-corrosion coating disclosed by the presen...

Embodiment 2

[0041] The component A is composed of the following components in parts by weight: 27 parts of epoxy resin, 12 parts of dibutyl phthalate, 8 parts of acrylic emulsion, 10 parts of garlic extract, 12 parts of marigold extract, dispersion 3 parts of emulsifier, 4 parts of emulsifier, 10 parts of anti-rust pigment, 12 parts of deionized water;

[0042] The component B is composed of the following components by weight: 8 parts of silicon dioxide powder, 6 parts of copper powder, and 4 parts of kaolin;

[0043] The preparation method of the water-based environmental protection anti-corrosion coating is as follows: each raw material in the above-mentioned component A and component B is fully stirred and mixed through the production equipment of the water-based environmental protection anti-corrosion coating disclosed by the present invention, and stirred at a speed of 60r / min, After the mixing is completed, vacuumize it to remove air bubbles, and then obtain the water-based environm...

Embodiment 3

[0045] The water-based environmentally friendly anti-corrosion coating is formed by mixing component A and component B through stirring equipment:

[0046]The component A is composed of the following components in parts by weight: 30 parts of epoxy resin, 12 parts of dibutyl phthalate, 5 parts of acrylic acid emulsion, 12 parts of garlic extract, 10 parts of marigold extract, dispersed 3 parts of agent, 6 parts of emulsifier, 10 parts of anti-rust pigment, 13 parts of deionized water;

[0047] The component B is composed of the following components by weight: 7 parts of silicon dioxide powder, 5 parts of copper powder, and 4 parts of kaolin;

[0048] The preparation method of the water-based environmental protection anti-corrosion coating is as follows: each raw material in the above-mentioned component A and component B is fully stirred and mixed through the production equipment of the water-based environmental protection anti-corrosion coating disclosed by the present invent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com