Tin-phosphorus-nitrogen intumescent flame-retardant polypropylene composite material and preparation method thereof

A flame retardant polypropylene and composite material technology, applied in the field of flame retardant polypropylene composite material preparation, can solve the problems of material mechanical property damage, excessive addition, etc., to prevent flame spread, improve carbonization performance, and improve flame retardant effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Weigh 747g of PP resin, 125g of piperazine pyrophosphate, 84g of melamine polyphosphate, 11g of pentaerythritol, and 20g of zinc stannate, place them in a drying oven at 60°C for 12 hours, then pour them into a small high-speed mixer, and then Weigh 5g tetrakis[β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate] pentaerythritol ester (antioxidant 1010), 3g N,N-ethylene bisstearamide, 3g polytetrafluoroethylene Vinyl fluoride powder and 2g of vinyltrimethoxysilane were poured into a high-speed mixer and mixed at a low speed for 8 minutes; Nitrogen-expandable flame-retardant polypropylene composite material 1kg, wherein the extrusion temperature of the twin-screw extruder is 180~195℃, the speed is 40~50rpm, and the feeding speed is 4~5.5Hz;

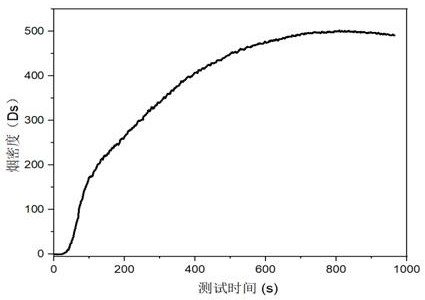

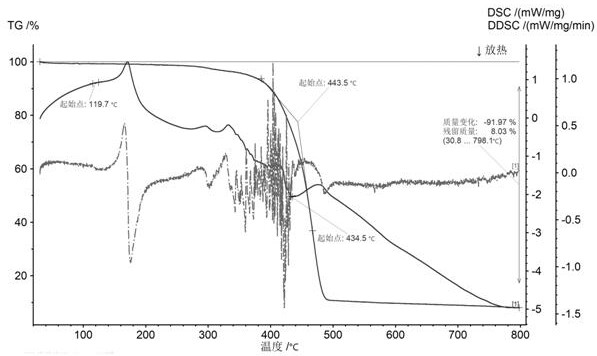

[0026] The composite material was injected into the injection molding machine to produce a test sample, and the limiting oxygen index test, UL-94 vertical combustion level test, and flameless smoke density test were performed on it. Th...

Embodiment 2

[0028] Weigh 727g of PP resin, 140g of piperazine pyrophosphate, 93g of melamine polyphosphate, 12g of triazine char-forming agent, and 15g of zinc hydroxystannate, and place them in a drying oven at 70°C for 12 hours, then pour them into a small high-speed mixer machine, then weigh 5g of tetrakis[β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate] pentaerythritol ester (antioxidant 1010), 3g of N,N-ethylene bisstearamide , 3g of polytetrafluoroethylene powder, 2g of vinyltrimethoxysilane are poured into a high-speed mixer and mixed for 10 minutes at low speed; - Phosphorus-nitrogen intumescent flame-retardant polypropylene composite material 1kg, wherein the extrusion temperature of the twin-screw extruder is 180~195℃, the speed is 40~50rpm, and the feeding speed is 4~5.5Hz;

[0029]The masterbatch was injected into the injection molding machine to produce test samples, and the limiting oxygen index test, UL-94 vertical combustion level test, and flameless smoke density test we...

Embodiment 3

[0031] Weigh 747g of PP resin, 125g of piperazine polyphosphate, 84g of melamine phosphate, 11g of dipentaerythritol, and 20g of zinc stannate, place them in a drying oven and dry them at 80°C for 12 hours, then pour them into a small high-speed mixer, and then Weigh 5g tetrakis[β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate] pentaerythritol ester (antioxidant 1010), 3g zinc stearate, 3g polytetrafluoroethylene powder, 2g ethylene Pour triethoxysilane into a high-speed mixer and mix at a low speed for 9 minutes; then put the mixture into a twin-screw extruder for melt blending, extrusion, and granulation to obtain tin-phosphorus-nitrogen intumescent flame-retardant polypropylene Composite material 1kg, wherein the extrusion temperature of the twin-screw extruder is 180~195℃, the speed is 40~50rpm, and the feeding speed is 4~5.5Hz;

[0032] The masterbatch was injected into the injection molding machine to produce test samples, and the limiting oxygen index test, UL-94 vertic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com