Mineralized artificial periosteum, preparation method and application thereof

A technology of artificial bone and mineralized collagen, which is applied in the fields of medical formula, medical science, prosthesis, etc., can solve the problems of connective tissue ingrowth, achieve good mechanical properties and degradation properties, promote bone healing ability, and improve repair effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

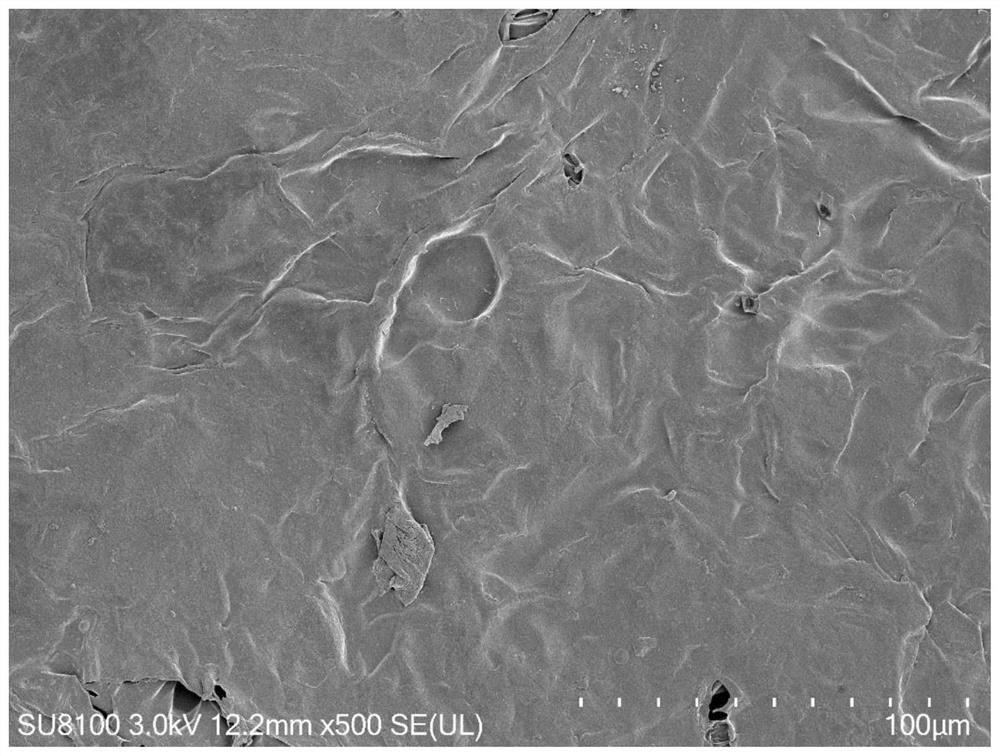

Image

Examples

preparation example Construction

[0054] According to a typical embodiment of the present invention, a preparation method of mineralized artificial periosteum is provided, the method comprising:

[0055] S1, the preparation of dense layer, specifically include:

[0056] S1-1. Dissolving silk fibroin in lithium bromide solution or calcium chloride ternary system (calcium chloride / water / ethanol molar ratio 1:8:2) solution to obtain silk fibroin with a mass fraction of 5% to 20% protein solution.

[0057] The silk fibroin is selected from the natural high-molecular fiber protein extracted from silkworm cocoons or silk, and the mass fraction of silk fibroin in the silk fibroin solution is 5% to 20%. The reason: too high mass fraction of silk fibroin is not conducive to Degradation is slow during dissolution and use, and the low mass fraction affects the mechanical properties and physical barrier function of the membrane;

[0058] S1-2, taking the silk fibroin solution obtained in step S1-1 and injecting it into ...

Embodiment 1

[0096] A preparation method of mineralized artificial periosteum, the method comprising:

[0097] S1, the preparation of dense layer, specifically include:

[0098] S1-1. Dissolving silk fibroin in lithium bromide solution or calcium chloride ternary system (calcium chloride / water / ethanol molar ratio 1:8:2) solution to obtain a silk fibroin solution with a mass fraction of 5%.

[0099] S1-2. Take the silk fibroin solution obtained in step S1-1 and inject it into the mold, pre-freeze at -60°C for 12 hours, then dry the frozen body at a temperature of 10°C and a pressure of 10Pa for 48 hours, and then mold it under a pressure of 20MPa 60s to obtain dense layer film;

[0100] Thermally cross-linking the dense layer film at 110° C. for 24 hours in a vacuum oven to obtain a dense layer;

[0101] S2, the preparation of mineralized collagen solution, specifically include:

[0102] S2-1. Dissolving type I collagen in an acetic acid solution with a mass fraction of 5%, wherein the c...

Embodiment 2

[0111] A preparation method of mineralized artificial periosteum, the method comprising:

[0112] S1, the preparation of dense layer, specifically include:

[0113] S1-1. Dissolving silk fibroin in lithium bromide solution or calcium chloride ternary system (calcium chloride / water / ethanol molar ratio 1:8:2) solution to obtain a silk fibroin solution with a mass fraction of 5%.

[0114] S1-2. Take the silk fibroin solution obtained in step S1-1 and inject it into the mold, pre-freeze at -60°C for 12 hours, then dry the frozen body at a temperature of 10°C and a pressure of 10Pa for 48 hours, and then mold it under a pressure of 20MPa 30s to obtain dense layer film;

[0115] Thermally cross-linking the dense layer film at 110° C. for 24 hours in a vacuum oven to obtain a dense layer;

[0116] S2, the preparation of mineralized collagen solution, specifically include:

[0117] S2-1. Dissolving type I collagen in an acetic acid solution with a mass fraction of 5%, wherein the c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com