Preparation method and application of silicon-based MEMS gas sensor chip

A gas sensor and chip technology, which is applied in semiconductor/solid-state device components, instruments, scientific instruments, etc., can solve the problems of poor stability of silicon-based MEMS gas sensor chips, achieve consistent film thickness and specific surface area, and strengthen interface bonding Increased strength, improved consistency and job stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

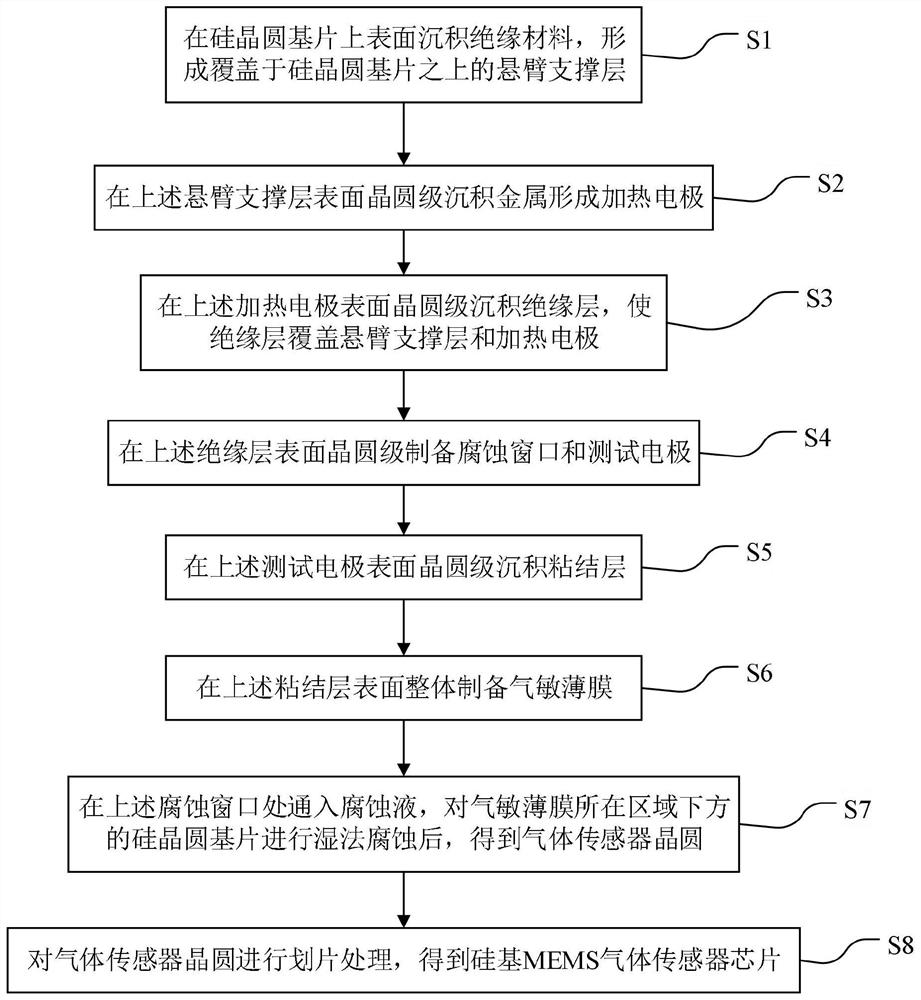

[0046] A method for preparing a silicon-based MEMS gas sensor chip, such as figure 1 shown, including the following steps:

[0047] S1. Depositing an insulating material on the upper surface of the silicon wafer substrate to form a cantilever support layer covering the silicon wafer substrate;

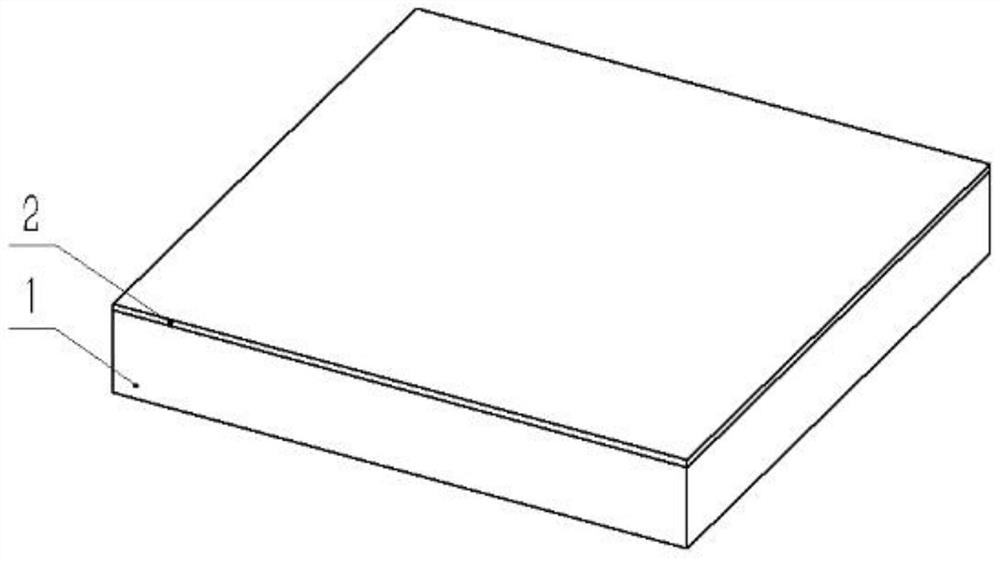

[0048] Specifically, such as figure 2 As shown, a cantilever support layer 2 is prepared on the surface of a substrate silicon wafer 1 . The insulating material can be oxide or nitride or a mixture of both, preferably an ONO composite film. In this embodiment, a silicon wafer of 4-12 inches is used as a substrate, and a support layer of silicon oxide, silicon nitride or a composite film (total thickness 300nm-2um) is prepared on the substrate by thermal oxidation growth, PECVD or LPCVD process.

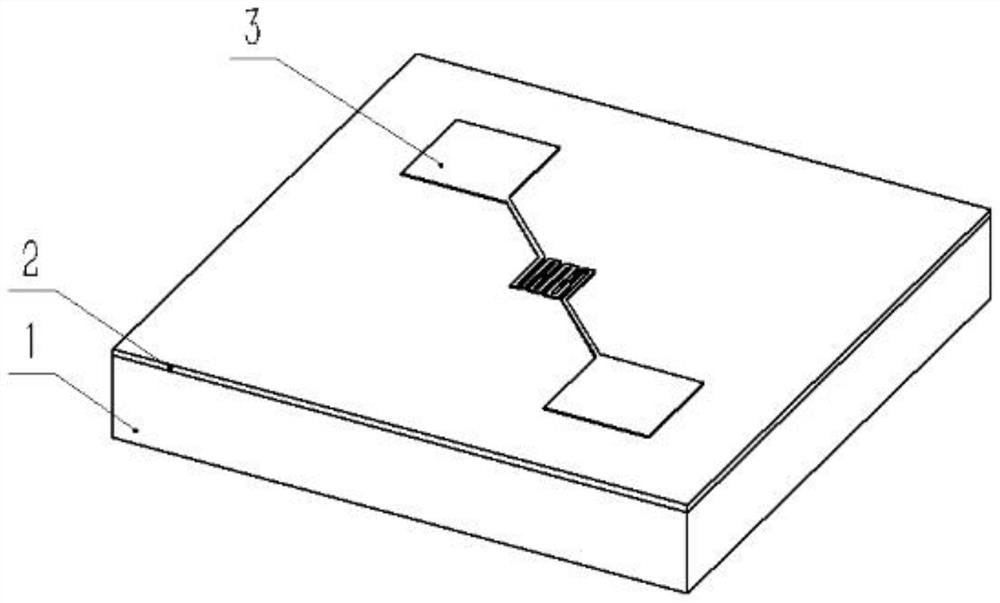

[0049] S2. Wafer-level lithography on the surface of the above-mentioned cantilever support layer and depositing metal to form a heating electrode; wherein, the material of the heating ele...

Embodiment 2

[0068] A silicon-based MEMS gas sensor chip, prepared by the method for preparing a silicon-based MEMS gas sensor chip provided in Example 1.

[0069] The relevant technical solutions are the same as those in Embodiment 1, and will not be repeated here.

Embodiment 3

[0071] Such as Figure 10 As shown, a silicon-based MEMS gas sensor chip includes gas sensors arranged in an array; the gas sensor includes silicon wafer substrate units, cantilever support units, heating electrodes, insulating layers, test electrodes, Adhesive layers and gas sensitive films;

[0072] Among them, the uppermost layer is a gas-sensitive film; the oxidation-reduction reaction on the surface of the gas-sensitive film before and after gas adsorption leads to a change in its electrical conductivity; based on this semiconductor property, the gas-sensitive film is used to convert the change of target gas information into its own conductivity change; wherein, the target gas information includes the type and / or concentration of the target gas. Specifically, the material of the gas-sensitive thin film may be an N-type semiconductor, a P-type semiconductor, or the like.

[0073] The material of the adhesive layer is the same as that of the gas-sensitive film, and is use...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com