Vertical cavity surface emitting laser and manufacturing method thereof

A vertical cavity surface emission and laser technology, applied in lasers, laser parts, semiconductor lasers, etc., can solve the problems of restricting large-scale applications and immature processes, avoiding oxidation and multiple epitaxy processes, and reducing the difficulty of epitaxial growth. , avoid difficult effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

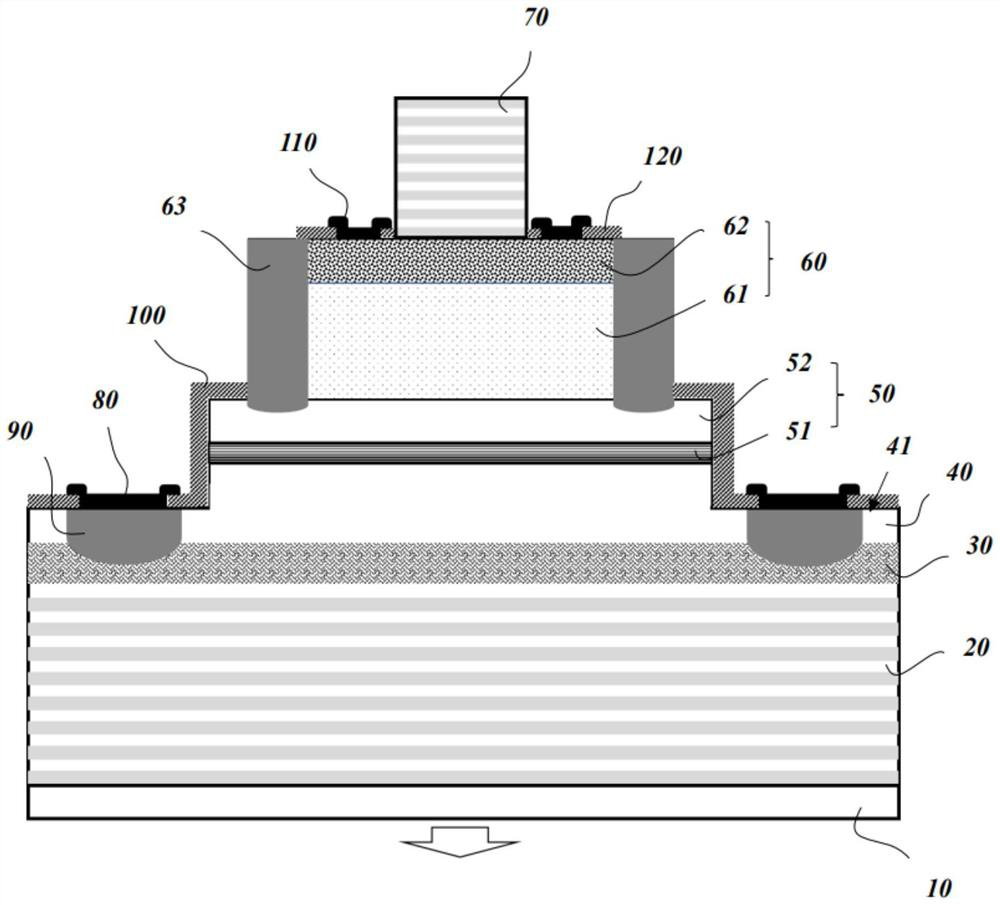

[0060] Provide a specific embodiment of a vertical cavity surface emitting laser, including a substrate 10, and a first Bragg mirror 20, a first contact layer 30, a lower cladding layer 40, an active layer 51, The upper cladding layer 52 , the current spreading layer 61 , the second contact layer 62 and the second Bragg mirror 70 .

[0061] The outer diameter of the second Bragg reflector 70 is smaller than the outer diameter of the second contact region 62, and a passivation layer 120 is arranged on the exposed surface of the second contact region 62, and a window is opened on the passivation layer 120, and a second contact region is arranged in the window. Two electrodes 110 .

[0062] The outer diameters of the current spreading layer 61 and the second contact region 62 are smaller than that of the upper cladding layer 52 and form the second mesa 60 . The side p-type diffusion of the second mesa 60 adopts Zn as a dopant, and the Zn diffusion concentration is 4E18cm -3 , a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com