Device for upgrading bio-oil by using Fe/Ni bimetallic modified ZSM-5 catalyst and method thereof

A ZSM-5, catalyst technology, applied in the field of biomass energy, can solve the problems of insufficient hydrocarbons and high oxygen content, and achieve the effect of improving acidity and pore structure, increasing content, improving catalytic activity and deoxidizing ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

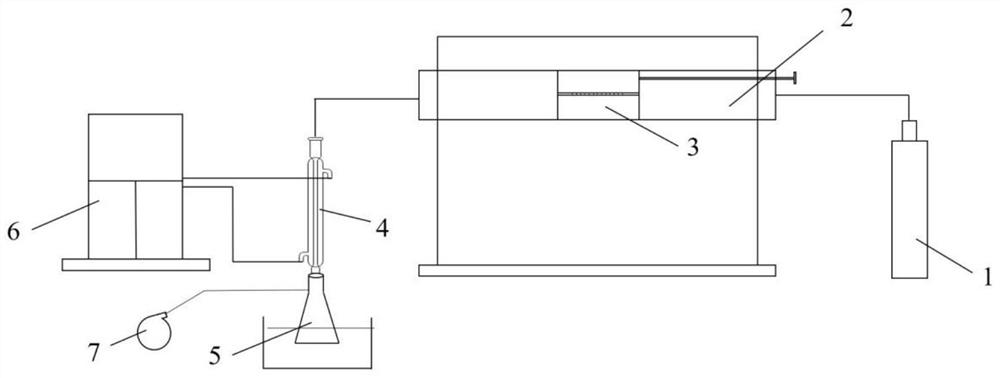

[0052] S1. Select ZSM-5 catalyst with a silicon-aluminum ratio of 25 as the parent catalyst, calcinate the parent catalyst at 550°C for 5 hours, then grind and sieve to ensure that the particle size is 0.25-0.85mm. Take an appropriate amount of ZSM-5 catalyst and slowly add it to 2-6wt.% Fe / Ni nitrate solution, keep stirring at 40°C for about 2 hours to form a paste, then dry it at 105°C for 12 hours. Then, it was put into a muffle furnace and calcined at 550° C. for 5 hours. After being taken out, it is ground into powder and sieved to a particle size of 0.18-0.25 mm to prepare a Fe / Ni bimetallic modified ZSM-5 molecular sieve catalyst.

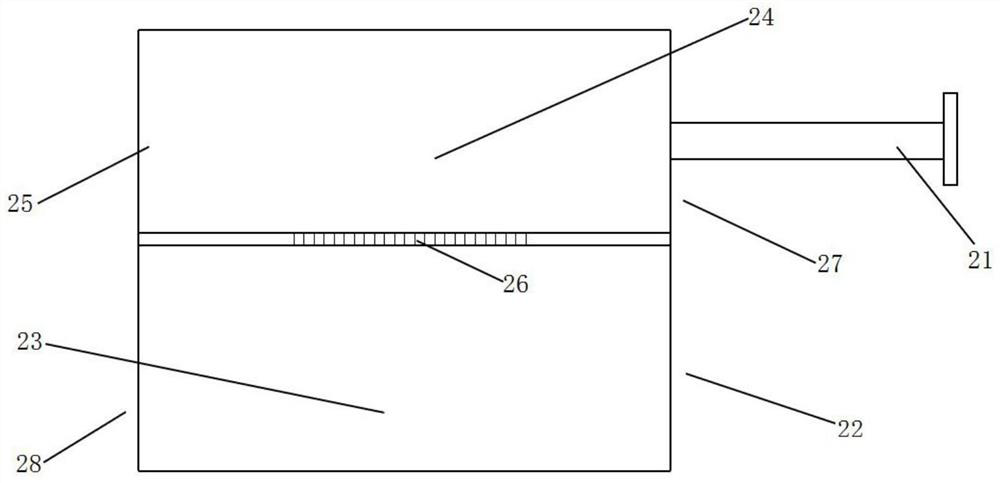

[0053] S2, take by weighing 20g Fe / Ni bimetallic modified ZSM-5 molecular sieve catalyst and 20g poplar sawdust respectively, and place respectively the catalyst bed and the biomass bed of the catalytic bed reactor, then place it in the fixed bed reactor import side.

[0054] S3. Set the temperature of the fixed-bed reactor to 550°C. After...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com