Ammoxidationcatalyst for synthesizing methacrylonitrile, and preparation method thereof

A technology of methacrylonitrile and catalyst, which is applied in the direction of hydrocarbon ammoxidation preparation, metal/metal oxide/metal hydroxide catalyst, physical/chemical process catalyst, etc. It can solve the problems of long catalytic reaction time, catalytic reaction activity and production The efficiency needs to be further improved and other issues, to achieve excellent catalytic performance, mild reaction conditions, and reduce production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

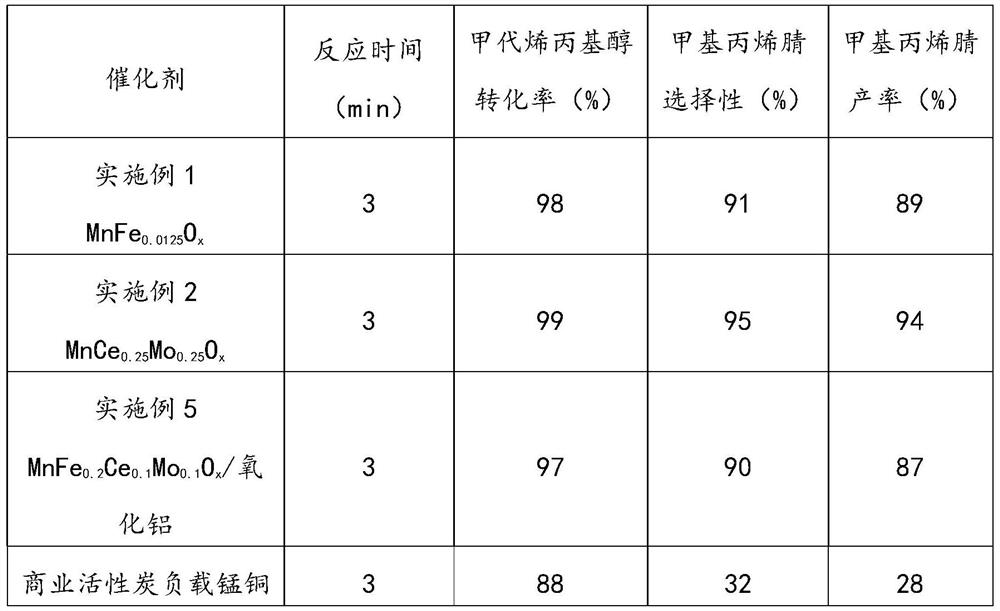

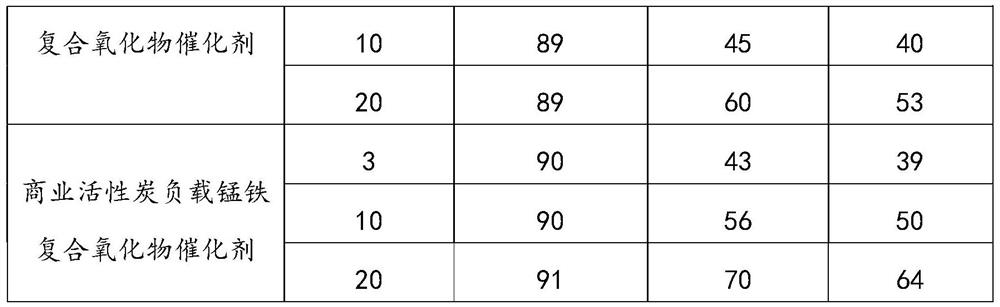

Examples

Embodiment 1

[0032] MnFe 0.0125 o x Composite oxide catalyst preparation. Weigh 15.8g potassium permanganate solid, add 600mL deionized water, stir to dissolve; weigh 75.3g manganese nitrate tetrahydrate solid, add 50mL deionized water, stir to dissolve; weigh 0.811g ferric chloride solid, add 50mL to Ionized water, stirring to dissolve; under stirring, slowly add manganese nitrate solution to potassium permanganate solution, and stir at room temperature for 0.5h; under stirring, slowly add ferric chloride solution to the above solution, and Stir at low temperature for 0.5h; slowly add 200mL of 2M sodium hydroxide solution to the above solution, and stir at room temperature for 5h; The melting temperature is 100°C, and the time is 12h; the kettle is opened, the solution is filtered, the solid is washed with deionized water three times, and dried in an oven at 120°C for 6h; finally, it is roasted in a muffle furnace at 300°C for 5h to obtain MnFe 0.0125 o x composite oxide catalyst.

Embodiment 2

[0034] MnCe 0.25 Mo 0.25 o xComposite oxide catalyst preparation. Weigh 15.8g potassium permanganate solid, add 150mL deionized water, stir to dissolve; weigh 17.3g manganese acetate solid and 33.8g manganese sulfate monohydrate, add 100mL deionized water, stir to dissolve; weigh 43.4g hexahydrate nitric acid Cerium, 32.6g molybdenum acetylacetonate solid, add 200mL deionized water, stir to dissolve; under stirring, slowly add manganese acetate and manganese sulfate solution into potassium permanganate solution, and stir at room temperature for 0.5h; under stirring, Slowly add cerium nitrate and molybdenum acetylacetonate solution to the above solution, and stir at room temperature for 2h; slowly add 25% ammonia solution 612g to the above solution, and stir at room temperature for 12h; Carry out high-temperature crystallization in a crystallization kettle lined with tetrafluoroethylene, the crystallization temperature is 120°C, and the time is 12h; Dry at 80°C for 12h; fin...

Embodiment 3

[0036] MnCe 0.167 Ni 0.25 o x Composite oxide catalyst preparation. Weigh 19.7g potassium manganate solid, add 300mL deionized water, stir to dissolve; weigh 9.9g manganese chloride tetrahydrate solid, add 990mL deionized water, stir to dissolve; weigh 13.7g cerium ammonium nitrate, 10.9g hexahydrate Nickel nitrate solid, add 500mL deionized water, stir to dissolve; under stirring, slowly add manganese chloride solution to potassium manganate solution, and stir at room temperature for 1h; under stirring, mix ammonium cerium nitrate and nickel nitrate solution Slowly added to the above solution, and stirred at room temperature for 1 h; slowly added 250 g of urea solution with a mass fraction of 50% to the above solution, and stirred at room temperature for 24 h; Carry out high-temperature crystallization in a crystallization kettle, the crystallization temperature is 180°C, and the time is 48h; the kettle is opened, the solution is filtered, the solid is washed with ethanol ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com