Personalized 3D printing meniscus regeneration stent and preparation method thereof

A 3D printing and meniscus technology, applied in the field of medical prosthesis, can solve the problems of easy dislocation of meniscus bracket, large difference in heterogeneity distribution, poor cartilage protection effect of meniscus tissue, etc., to achieve enhanced regeneration and repair functions, Strengthen regeneration and repair, avoid dislocation and uneven stress distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

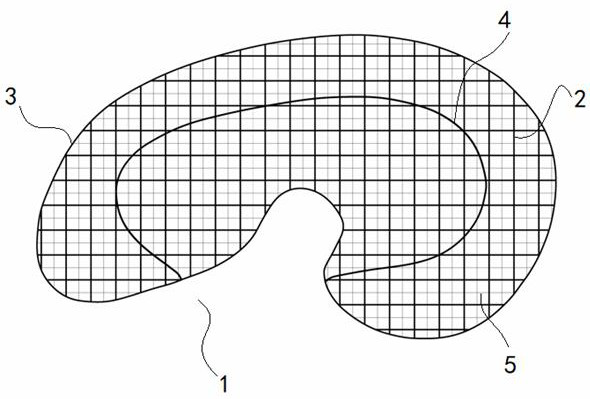

[0038] The purpose of this embodiment is to provide a method for preparing a personalized 3D printed meniscus regeneration bracket, including: preparing a bracket model and setting a support structure model for supporting the bracket model; The working parameters of the head and internal structure printing design; the extruded material in the high-temperature print head and the extruded material in the low-temperature print head are mixed and printed, and the inner 2 / 3 area of the meniscus regeneration bracket is set as the "white area" and the outer 1 The / 3 area was set as the "red area" to construct the meniscus regeneration scaffold by partition printing.

[0039] The working principle of the above-mentioned technical scheme is:

[0040]Using bio-3D printing technology, the original meniscus-shaped scaffold is constructed at 1:1. At the same time, in order to make the prepared scaffold implantable, it can match the tibial plateau at the bottom and the femoral condyle a...

Embodiment 2

[0044] According to the preparation method of a personalized 3D printed meniscus regenerative scaffold described in Embodiment 1, in step S1, after obtaining the nuclear magnetic image data of the knee joint, the nuclear magnetic data of the knee joint is imported into the medical reverse software Mimics to construct a three-dimensional model of the meniscus, and then The constructed three-dimensional meniscus model was imported into Geomagic reverse engineering software for triangular surface optimization to obtain the scaffold model to be prepared. The detailed steps of this process are as follows:

[0045] 1. Knee joint MRI imaging and 3D model construction

[0046] Use a 3.0T nuclear magnetic resonance instrument to scan the knee joint to obtain the knee joint nuclear magnetic resonance image. The nuclear magnetic resonance scanning sequence is PD-FSE-SPIR, and the specific parameters are: repetition time (TR): 2915.0 milliseconds, echo time (TE): 39.4 millisecond. Then ...

Embodiment 3

[0055] According to the preparation method of a personalized 3D printed meniscus regeneration bracket described in Embodiment 2, in step S1, the support structure model is designed according to the bracket model, so that during 3D printing, there is an empty gap between the bracket model and the printing platform Filled by supporting structure model;

[0056] Wherein, the internal structure of the support structure model is the same as that of the model printed by the high temperature print head.

[0057] Specifically, Pluronic F127 is selected as the material for printing the support structure model. Pluronic F127 has the following typical advantages: 1. It can be printed at room temperature; 2. It has excellent rheological properties and high printing fidelity ;3. Pluronic F127 is a non-ionic surfactant that is soluble in water, so after printing, soak the meniscus bracket in water to completely remove the support structure;

[0058] The beneficial effect of the above techn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com