Preparation and preservation method of rice and potato modified starch composite gel

A technology of modified starch and composite gel, which is applied in the field of food processing, can solve problems such as poor quality, short shelf life, food variability, etc., and achieve good sterilization and freshness preservation effects, reduce the number of microorganisms, and lower the glycemic index.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] (1) Potato starch is prepared into a starch-water mixture with a mass fraction of 10%, enzymatically hydrolyzed at 60° C. for 2 hours with pullulanase (added in an amount of 0.1% of the mass of the starch-water mixture), and dried to obtain potato modified starch;

[0052] (2) After washing the rice, soak it for 12 hours at a temperature of 4°C at a rice water ratio of 1:1.2 (mass ratio);

[0053] (3) The soaked rice is ground with water at a rice-to-water ratio of 1:1 (mass ratio) to obtain a composite slurry. Take 7 parts of the composite slurry, each 500g, and add the steps in the above slurry according to the ratio in Table 1. (1) The modified potato starch obtained is mixed;

[0054] (4) Steam the slurry mixed with modified potato starch at 100°C for 3 minutes, cut into uniform strips, and let stand at 40°C for 2 hours to obtain the rice and potato modified starch composite gels of experimental groups 1-7;

[0055] (5) The rice and potato modified starch composite...

Embodiment 2

[0064] (1) Potato starch is prepared into a starch-water mixture with a mass fraction of 10%, enzymatically hydrolyzed at 55° C. for 2 hours with pullulanase (the addition amount is 0.1% of the mass of the starch-water mixture), and dried to obtain potato modified starch;

[0065] (2) After washing the rice, soak it for 12 hours at a temperature of 4°C at a rice water ratio of 1:1.2 (mass ratio);

[0066] (3) The soaked rice is ground with water at a ratio of rice to water of 1:1 (mass ratio) to obtain a slurry, take 500 g of the slurry, add 25 g of the potato modified starch obtained in step (1) and mix well,

[0067] (4) Steam the slurry mixed with modified potato starch at 100°C for 3 minutes, cut into uniform strips, and stand at 40°C for 2 hours to obtain a composite gel of rice and potato modified starch.

Embodiment 3

[0069] (1) Potato starch is prepared into a starch-water mixture with a mass fraction of 10%, enzymatically hydrolyzed at 65° C. for 2 hours with pullulanase (added in an amount of 0.1% of the mass of the starch-water mixture), and dried to obtain potato modified starch;

[0070] (2) After washing the rice, soak it for 12 hours at a temperature of 4°C at a rice water ratio of 1:1.2 (mass ratio);

[0071] (3) The soaked rice is ground with water at a rice-to-water ratio of 1:1 (mass ratio) to obtain a slurry, take 500 g of the slurry, add 50 g of the potato modified starch obtained in step (1) and mix well,

[0072] (4) Steam the slurry mixed with modified potato starch at 100° C. for 3 minutes, cut into uniform strips, and stand at 40° C. for 2 hours to obtain a composite gel of rice and potato modified starch.

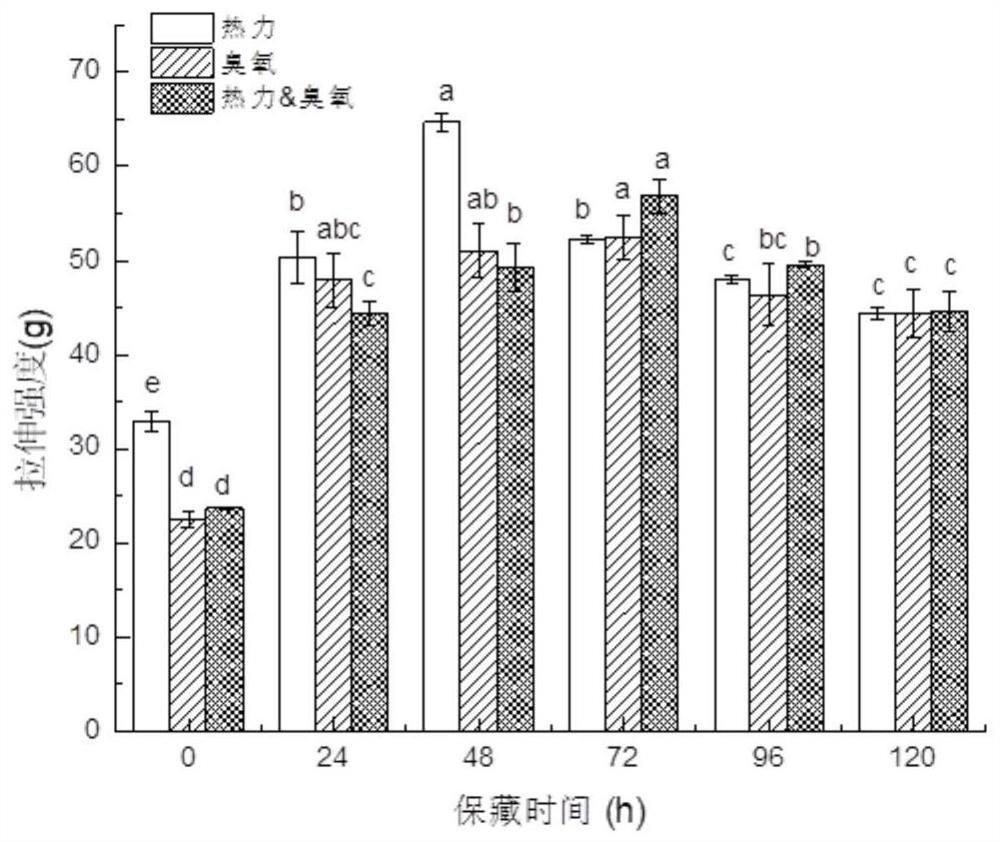

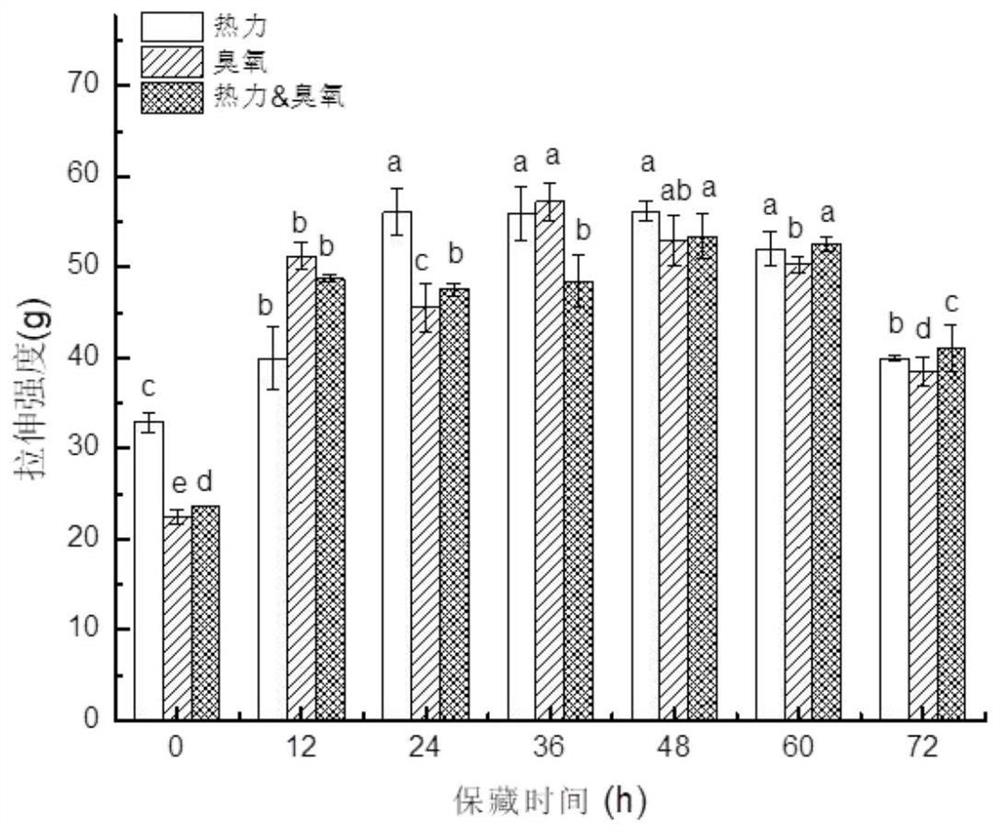

[0073] The rice and potato modified starch composite gels obtained in Example 2 and Example 3 were tested for TPA, tensile strength, strip breaking rate and iodine bl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com