Method for reducing cutting error of capacitor and battery metal foil cutter

A metal foil and capacitor technology, applied in metal material coating process, vacuum evaporation plating, coating and other directions, can solve the problems of no capacitor, large surface roughness of the coating, large production loss, etc., and achieve error consistency control Good, improve the surface finish, prolong the service life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

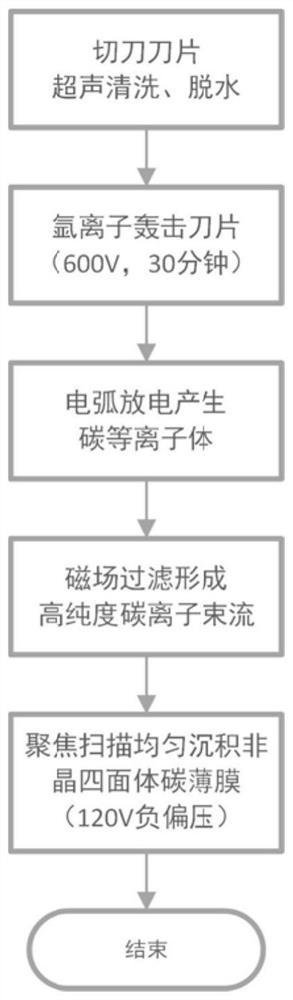

[0046] A method for reducing the cutting error of capacitors and battery metal foil cutters, the specific implementation steps are:

[0047] (1) Ultrasonic cleaning: Put the capacitor to be coated and the metal foil cutter of the battery into the ultrasonic cleaning tank to clean and remove the grease. When removing the oil, the cleaning liquid needs to be heated to 70 degrees, then dehydrated and dried, and then placed in a vacuum chamber;

[0048] (2) Ion beam polishing, turn on the cold cathode gas ion source, the ion source input argon, the flow rate is 50 ml / s, the discharge voltage is 500V, and the extraction voltage is 600V, and the extracted argon ions are used to impact the surface of the metal foil cutter in the vacuum chamber Perform ion beam polishing treatment, and the treatment time is controlled at 30 minutes;

[0049] (3) Turn off the gas ion source, turn on the arc ion source, the cathode target and anode cylinder of the arc source are high-purity graphite, th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface roughness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com