A kind of low-gloss type water-based epoxy ester coating for steel structure and preparation method thereof

A low-gloss, steel structure technology, applied in the coating and other directions, can solve the problems of the original paint defoaming performance, the negative effect of the recoating performance, the peculiar smell, and the lack of low-gloss paint. Soft film gloss and good early water resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

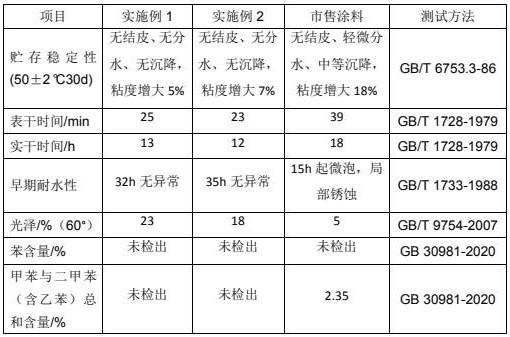

Examples

Embodiment 1

[0056] The low-gloss water-based epoxy ester coating for steel structures in this example consists of 312g of vinyl modified epoxy ester resin, 11g of dimethylethanolamine, 9g of ammonia water (28% by mass), and dispersant Dispex Ultra PX 4585 (Germany BASF) 4g, propylene glycol butyl ether 10g, drier ADDITOL VXW 6206 (Allnex Thailand) 3.6g, methyl ethyl ketone oxime 2.0g, AFCONA2502 (Efcona, Netherlands) 1.2g, lemon yellow 6.0g, iron red 1.0 g. Titanium dioxide 88g, MA-100 carbon black (produced by Mitsubishi, Japan) 5.0g, superfine barium sulfate (produced by Hunan Ruishi) 180g, defoamer TEGO Airex 902 W (produced by Evonik, Germany) 1.0g, anti-flash rust Agent FA179 (Deqian Hemings) 5.0g, BYK-333 leveling agent (Germany BYK) 1.5g, wetting agent ADDITOLXW 330 (Thailand allnex) 1.5g, thickener DeuRheo WT-105A ( Deqian Hemings) 2.0g and deionized water 500g prepared.

[0057] The preparation method of low light type water-based epoxy ester coating for steel structures of this...

Embodiment 2

[0064]The low-gloss water-based epoxy ester coating for steel structure in this embodiment consists of 312g of vinyl modified epoxy ester resin, 11g of dimethylethanolamine, 9g of ammonia (mass fraction is 28%), dispersant Tego Dispers 655 (Germany Win 4g, Propylene Glycol Butyl Ether 10g, Drier ADDITOL VXW 6206 (Allnex, Thailand) 3.6g, MEKOxime 2.0g, AFCONA2502 (Efcona, Netherlands) 1.2g, Lemon Yellow 6.0g, Iron Red 1.0 g, 88g of titanium dioxide, 5.0g of MA-100 carbon black (produced by Mitsubishi, Japan), 180g of superfine barium sulfate (produced by Hunan Ruishi), 1.0g of defoamer Foamex 845 (produced by Evonik, Germany), anti-flash rust agent FA179 (produced by Deqian Hemings) 5.0g, leveling agent BYK-333 (produced by BYK, Germany) 1.5g, wetting agent Vesmody_U605 (produced by Wanhua Chemical) 1.5g, thickener TEGO ViscoPlus 3000 (produced by Evonik, Germany) ) 2.0g and 500g deionized water.

[0065] During the preparation of vinyl-modified epoxy ester resin in this examp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy equivalent | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com