Hexagonal biconical mononuclear dysprosium compound, preparation method and application thereof

A compound and bipyramidal technology, applied in the field of hexagonal bipyramidal mononuclear dysprosium compounds and their preparation, can solve the problems of inconvenient synthesis, easy decomposition or weathering, poor repetition effect, etc. High controllability and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

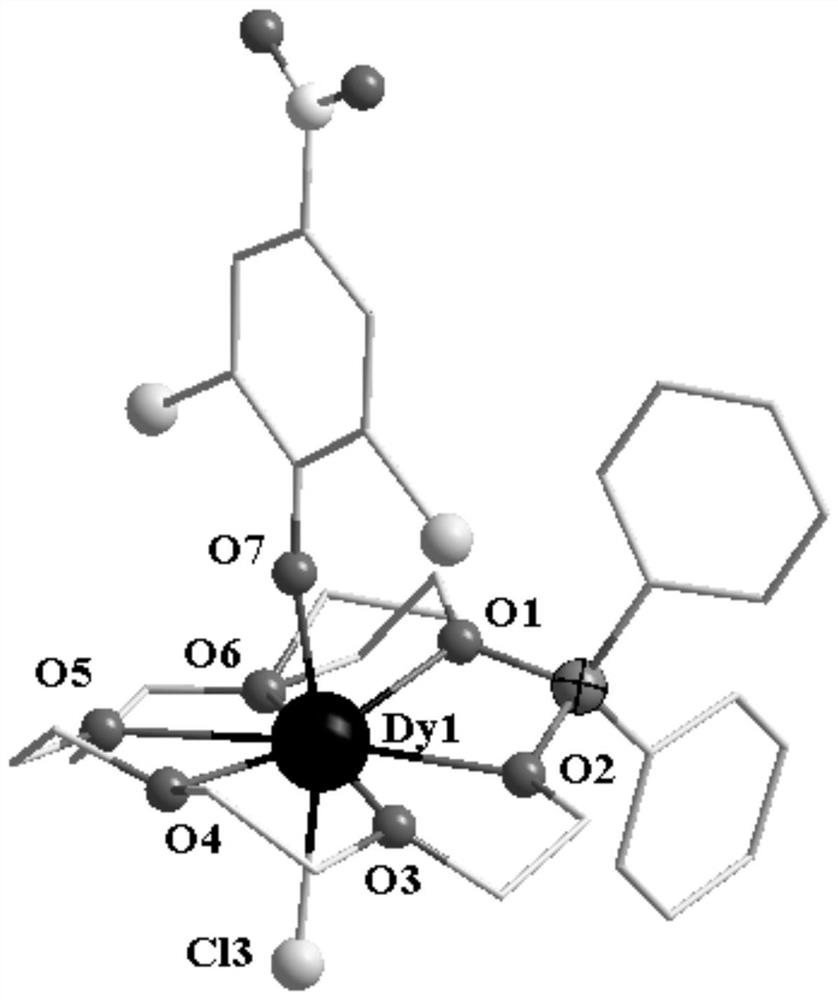

[0026] A synthetic method of a hexagonal bipyramidal mononuclear dysprosium compound with the behavior of a single-molecule magnet, comprising:

[0027] Step 1, 2,6-dichloro-4-nitrophenol (0.5mmol) and NaH (0.5mmol) were dissolved in 15mL water-dichloromethane (1:1) mixed solvent, and then DyCl 3 ·6H 2 O (0.5mmol) and pentaethylene glycol (0.5mmol) were added in, stirred for 1 hour, and a yellow suspension was obtained.

[0028] Step 2. Take NaBPh 4 (0.5mmol) was added to the above suspension, heated to 100°C and refluxed for 4 hours, cooled to room temperature, separated the dichloromethane layer with a separatory funnel, transferred to a test tube, slowly dripped 30mL of n-hexane to form two The phases were separated, and the crystals of dysprosium single-ion magnets were obtained after 4 days.

[0029] The yield of the dysprosium single-ion magnet prepared in this example is 41.8%, and the purity is above 99%.

Embodiment 2

[0031] A synthetic method of a hexagonal bipyramidal mononuclear dysprosium compound with the behavior of a single-molecule magnet, comprising:

[0032] Step 1, 2,6-dichloro-4-nitrophenol (0.3mmol) and NaH (0.3mmol) were dissolved in 10mL water-dichloromethane (1:1) mixed solvent, and then DyCl 3 ·6H 2 O (0.5mmol) and pentaethylene glycol (0.7mmol) were added in, stirred and reacted for 1 hour, and a yellow suspension was obtained.

[0033] Step 2. Take NaBPh 4 (0.5mmol) was added to the above suspension, heated to 100°C and refluxed for 4 hours, cooled to room temperature, separated the dichloromethane layer with a separatory funnel, transferred to a test tube, slowly dripped 20mL of n-hexane to form two The phases were separated, and the crystals of dysprosium single-ion magnets were obtained after 3 days.

[0034] The yield of the dysprosium single ion magnet prepared in this example is 38.5%, and the purity is above 99%.

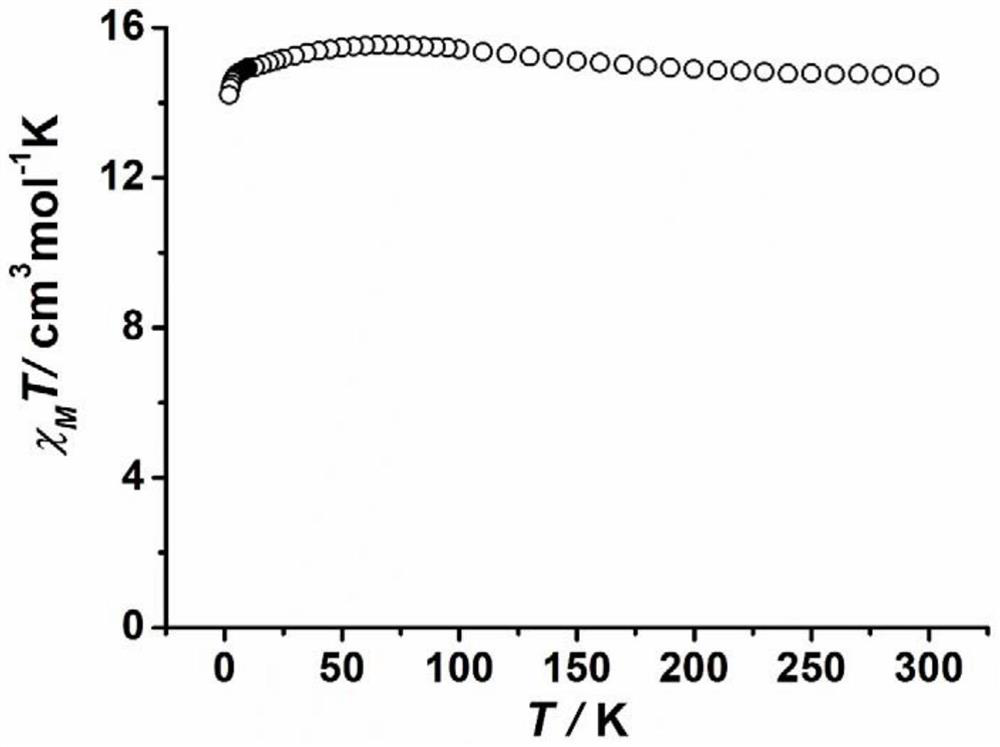

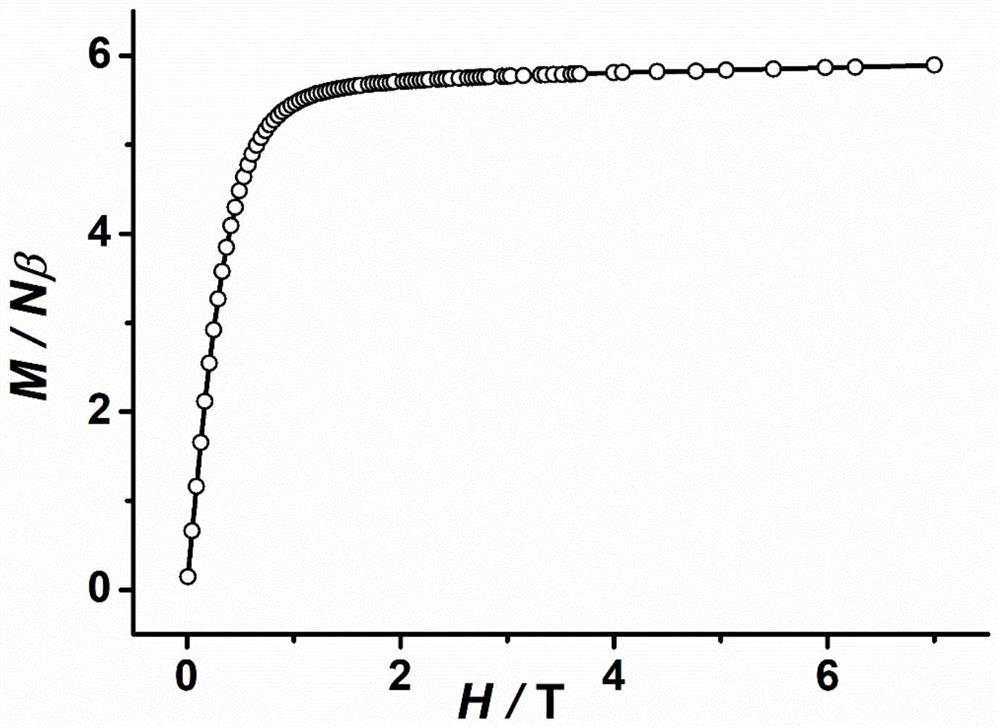

[0035] The characterization of the dysprosium ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com