SiBCN ceramic aerogel, preparation method and application thereof

A technology of airgel and ceramics, which is applied in the field of SiBCN ceramic airgel and its preparation, can solve the problems that there are no research reports on pure SiBCN ceramic airgel, achieve simple raw material composition and preparation process, excellent high temperature stability and high temperature Oxidation resistance, strong designability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0022] As mentioned above, the present invention provides a kind of preparation method of SiBCN ceramic airgel in the first invention, described method comprises the following steps:

[0023] (1) under the protection of an inert atmosphere, polyborosilazane is added as a precursor into an organic solvent and stirred evenly to prepare a precursor solution;

[0024] (2) Adding a catalytic amount of catalyst to the precursor solution and stirring evenly to obtain a wet gel precursor solution;

[0025] (3) performing a heating reaction on the wet gel precursor solution, and then cooling to room temperature to obtain a polyborosilazane wet gel;

[0026] (4) drying the polyborosilazane wet gel to obtain polyborosilazane airgel;

[0027] (5) placing the polyborosilazane airgel in an inert atmosphere for high-temperature pyrolysis conversion to obtain SiBCN ceramic airgel.

[0028] In some embodiments, the molecular structure of the polyborosilazane also contains -CH=CH 2 bond and ...

Embodiment 1

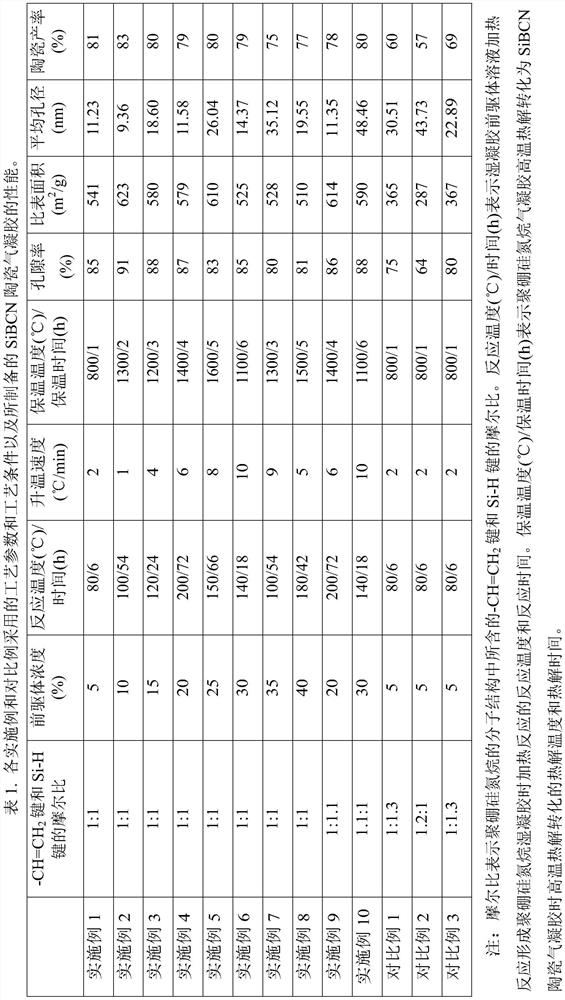

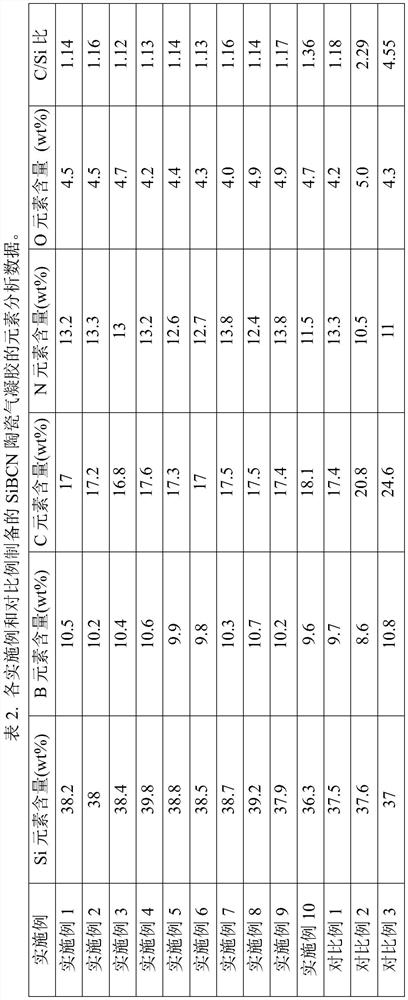

[0042] Under nitrogen protection, 2.5g polyborosilazane (-CH=CH contained in the molecular structure 2 The molar ratio of bond and Si-H bond is 1:1; unless otherwise specified, otherwise the same below) is added in 47.5g petroleum ether, stirs evenly, obtains the precursor solution that concentration is 5wt%; In this precursor solution Add 10ppm of Karstedt catalyst, stir evenly, transfer it to a pressure reactor filled with nitrogen, and react at 80°C for 6h to obtain a pale yellow polyborosilazane wet gel; after cooling to room temperature, take it out and soak it in Petroleum ether for 3 days, during which the petroleum ether was replaced 3 times (once a day); the wet gel was passed through supercritical CO 2 Dry to obtain polyborosilazane airgel; place the airgel in a high-temperature tube furnace, raise the temperature to 800°C at a rate of 2°C / min under a flowing nitrogen atmosphere, and keep it for 1 hour to obtain SiBCN ceramics The aerogels, their properties and elem...

Embodiment 2

[0044] Under the protection of nitrogen, 5g polyborosilazane was added to 45g tetrahydrofuran, and stirred evenly to obtain a precursor solution with a concentration of 10wt%; 20ppm of dicumyl peroxide was added to the precursor solution, and after stirring , transferred it to a pressure reactor filled with nitrogen, and reacted at 100°C for 54h to obtain a pale yellow polyborosilazane wet gel; after cooling to room temperature, it was taken out, soaked in tetrahydrofuran for 3 days, and tetrahydrofuran was replaced for 3 days time (once a day); the wet gel was freeze-dried to obtain polyborosilazane aerogel; the aerogel was placed in a high-temperature tube furnace, under a flowing nitrogen atmosphere, at a rate of 1° C. / min The temperature was raised to 1300°C and kept for 2 hours to obtain SiBCN ceramic airgel. Please refer to Tables 1 and 2 below for its properties and elemental analysis results.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com