Ultra-high molecular weight polyethylene processing formula

An ultra-high molecular weight, polyethylene technology, applied in the field of polyethylene processing, which can solve the problems of low shear rate, pores, and easy melt rupture.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

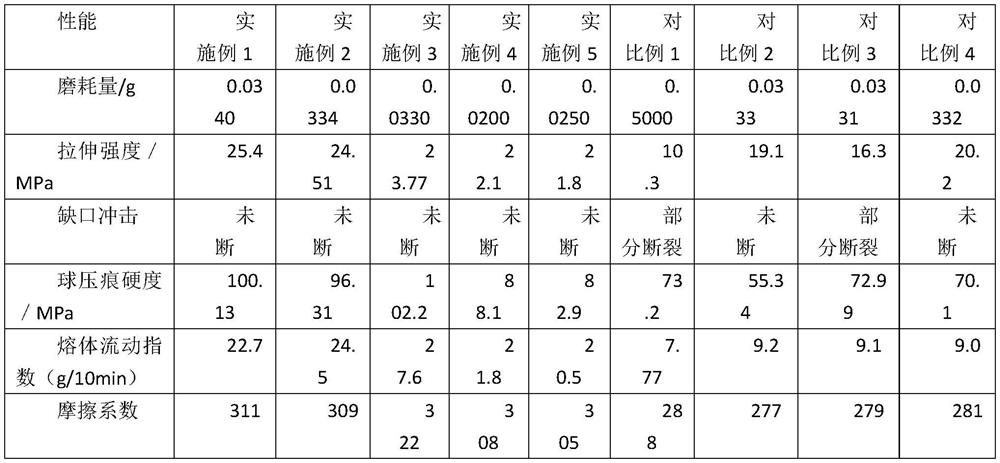

Examples

Embodiment 1

[0014] The ultra-high molecular weight polyethylene processing formula is composed of the following components by weight: 70 parts of UHMWPE, 10 parts of MDPE, 1 part of pyrogenic silica as a nucleating agent, 30 parts of liquid crystal polymer, 0.8 parts of flow modifier, and nano-layered silicate 3 copies. The average molecular weight of MDPE is less than 400,000.

[0015] The flow modifier is a high-efficiency flow modifier (MS2) researched by Xu Dingyu, Beijing University of Chemical Technology.

[0016] Ultra-high molecular weight polyethylene is processed and molded in a screw extruder, with an injection temperature of 240°C, a holding pressure of 5MPa, and an injection pressure of 10MPa. The injection mold temperature is 80°C, and the cooling time after injection is 1min.

Embodiment 2

[0018] The ultra-high molecular weight polyethylene processing formula consists of the following components by weight: 100 parts of UHMWPE, 40 parts of LDPE, 1.5 parts of nucleating agent silica, 5 parts of liquid crystal polymer, 1 part of flow modifier, nano-layered silicate 5 servings.

[0019] The flow modifier is a high-efficiency flow modifier (MS2) researched by Xu Dingyu, Beijing University of Chemical Technology.

[0020] Ultra-high molecular weight polyethylene is processed and molded in a screw extruder, with an injection temperature of 300°C, a holding pressure of 4MPa, and an injection pressure of 9MPa. The injection mold temperature is 60°C, and the cooling time after injection is 2 minutes.

Embodiment 3

[0022] The ultra-high molecular weight polyethylene processing formula consists of the following components by weight: 80 parts of UHMWPE, 250 parts of HDPE, 1.2 parts of nucleating agent sodium stearate, 20 parts of liquid crystal polymer, 0.9 parts of flow modifier, nano-layered silicic acid 4 parts of salt. The average molecular weight of HDPE is 400,000-500,000.

[0023] The flow modifier is a high-efficiency flow modifier (MS2) researched by Xu Dingyu, Beijing University of Chemical Technology.

[0024] Ultra-high molecular weight polyethylene is processed and molded in a screw extruder, with an injection temperature of 270°C, a holding pressure of 4.5MPa, and an injection pressure of 9MPa. The injection mold temperature is 70°C, and the cooling time after injection is 1.5min.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com