Antifouling digital protection glaze

A protective glaze and digital technology, applied in the field of ceramic tile production, can solve the problems of poor anti-fouling effect of the glaze layer, achieve high anti-fouling effect, improve anti-fouling effect, and increase density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Antifouling digital protective glaze, including: 240g of burnt gemstone, 20g of muscovite, 350g of quartz stone, 120g of kaolin, 30g of plant ash, 50g of burnt talc, 30g of ball clay, 20g of zeolite, 30g of garnet, 20g of pyrophyllite, Stone 220g, calcium carbonate 15g, barium carbonate 8g, borax 12g and zircon 80g. The plant ash is a product obtained after burning rice stalks.

[0032] The calcium carbonate is modified calcium carbonate. The preparation method of described modified calcium carbonate comprises:

[0033] Calcium carbonate 27g, cationic starch 1.5g, magnesium sulfate 1.5g, carbon powder 0.4g, barium sulfate 0.4g, polyimide 0.6g, epoxy resin 0.4g, polyoxysilane 1g, dimethylformamide 0.15g, Magnesium sulfide 0.4g, sepiolite fiber 0.4g, titanium dioxide 0.5g;

[0034] Add calcium carbonate, cationic starch, magnesium sulfate, carbon powder, barium sulfate, polyimide and stir between 70~80℃, adjust the pH to 10, keep stirring for 1~2h, adjust the pH to 7, ...

Embodiment 2

[0044] Antifouling digital protective glaze, including: 240g of burnt gemstone, 20g of muscovite, 350g of quartz stone, 120g of kaolin, 30g of plant ash, 50g of burnt talc, 30g of ball clay, 20g of zeolite, 30g of garnet, 20g of pyrophyllite, Stone 220g, calcium carbonate 15g, barium carbonate 8g, borax 12g and zircon 80g. The plant ash is a product obtained after burning rice stalks.

[0045] The preparation method of described glaze comprises:

[0046] Mix burnt gemstone, muscovite, quartz stone, kaolin, plant ash, burnt talc, ball clay, zeolite, garnet, pyrophyllite, albite, calcium carbonate, barium carbonate, borax and zircon, and then ball mill to obtain glaze material.

[0047] The glaze is used as the bottom glaze of ceramic tiles, and an intermediate layer and a top glaze are also arranged on the ceramic tiles;

[0048] The middle layer includes 250g of high-temperature frit and 350g of corundum. The high-temperature frit includes the following raw material compon...

experiment example

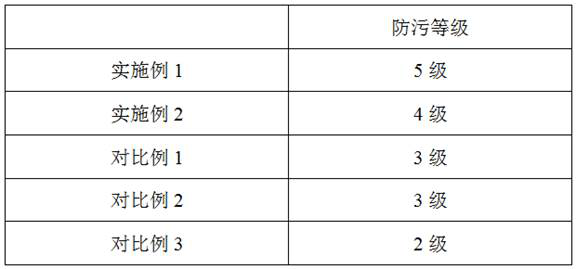

[0084] With reference to GB / T3810.14, the antifouling ability of the ceramic tiles made by each embodiment was tested. Wherein, the ceramic tiles in each embodiment are ground until the bottom glaze leaks out, and the bottom glaze of the same thickness is ground away.

[0085] Table 1 The antifouling ability of the ceramic tiles of each embodiment

[0086]

[0087] It can be seen from Table 1 that the antifouling digital protective glaze of the present application can also reach the highest antifouling level under the condition of wear.

[0088] The ceramic tile made of the bottom glaze glaze material of Example 1, under the situation of wear and tear, also can reach 5 grades of antifouling, shows that modified calcium carbonate and barium carbonate can promote glaze layer under different firing temperatures. The two-stage exhaust can fully release the gas in the glaze layer, improve the compactness of the glaze layer, and thus improve the antifouling ability of the glaze ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com