Preparation method of fiber diaphragm and pole piece

A fiber membrane and cathode material technology, applied in electrode manufacturing, electrode rolling/calendering, flat products, etc., can solve the problems of high technical difficulty, easy plugging holes, broken wires, etc., to improve energy density and safety. , The pole piece density is uniform and the effect of good adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] A kind of fiber diaphragm of ternary 622 positive electrode, its raw material composition is as follows:

[0051] Dispersed PTFE powder (particle size between 300μm-450μm, molecular weight greater than 1 million) 15g, conductive carbon black SP 10g, super conductive carbon black EC 10g and positive electrode 622 type nickel-cobalt-manganese ternary battery material 965g;

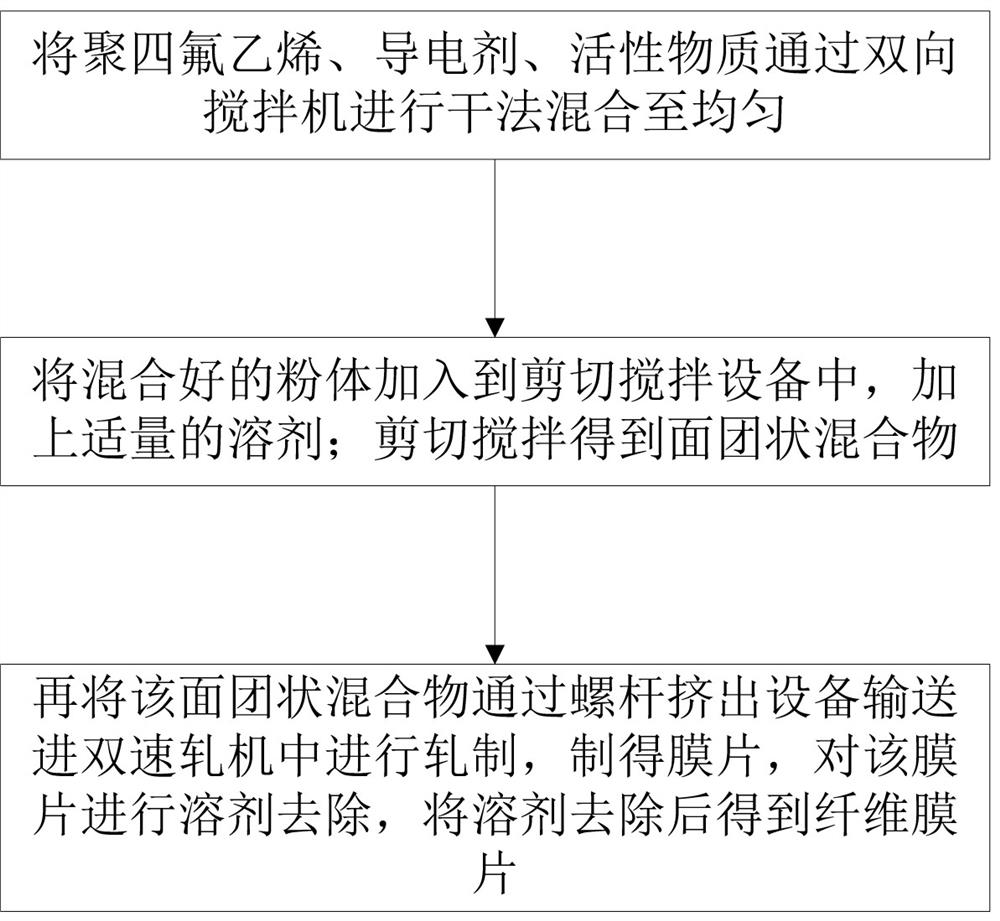

[0052] Its preparation method steps are as follows:

[0053] Step 1. Put the dispersed polytetrafluoroethylene powder, conductive carbon black SP, super conductive carbon black EC and 622 type nickel-cobalt-manganese ternary battery material in a two-way mixer to stir and mix to obtain a mixture in which the raw materials are uniformly dispersed. ; In order to prevent material segregation, the stirring speed of the present embodiment is set to 35r / min, and the stirring time is 180min;

[0054] Step 2. Put the mixture obtained in step 1 into a dough mixer, add 260g of ethylene glycol as a solvent to t...

Embodiment 2

[0058] A fibrous membrane of negative mesophase carbon microspheres, the raw material composition of which is as follows:

[0059] Dispersed PTFE powder (particle size between 300μm-450μm, molecular weight greater than 1 million) 10g, conductive graphite KS-6 30g, carbon nanotube CNTs 10g and negative electrode mesophase carbon microsphere battery material 950g;

[0060] The specific preparation method steps are as follows:

[0061] Step 1, placing the dispersed polytetrafluoroethylene powder, conductive graphite KS-6, carbon nanotubes CNTs and negative electrode mesophase carbon microsphere battery material in a two-way mixer, stirring and mixing, to obtain a mixture in which the raw materials are uniformly dispersed with each other; In order to prevent material segregation, in this example, the stirring speed was set to 45 r / min, and the stirring time was 240 min.

[0062] Step 2. Put the mixture obtained in step 1 into a dough mixer, add 350g of ethylene glycol as a solven...

Embodiment 3

[0066] Utilize the positive and negative electrode fiber membranes prepared in Examples 1 and 2 to prepare pole pieces, and the specific steps are as follows:

[0067] First coat the conductive slurry on both sides of the current collector, and then stick the fiber membrane on both sides of the current collector and press it by a rolling mill, dry it, and then roll it to obtain the polar structure of the fiber structure. piece;

[0068] The compaction density of the fiber membranes attached to both sides of the current collector, the positive electrode is 3.4g / cm 3 ; negative electrode is 1.5g / cm 3 ; The thickness of the fiber membranes attached to both sides of the current collector, the single-sided positive electrode is 140 μm, and the single-sided surface density is 47.6 mg / cm 2 ; The single-sided negative electrode is 160 μm, and the single-sided density is 24 mg / cm 2 ; Then make a soft pack battery for electrical performance test.

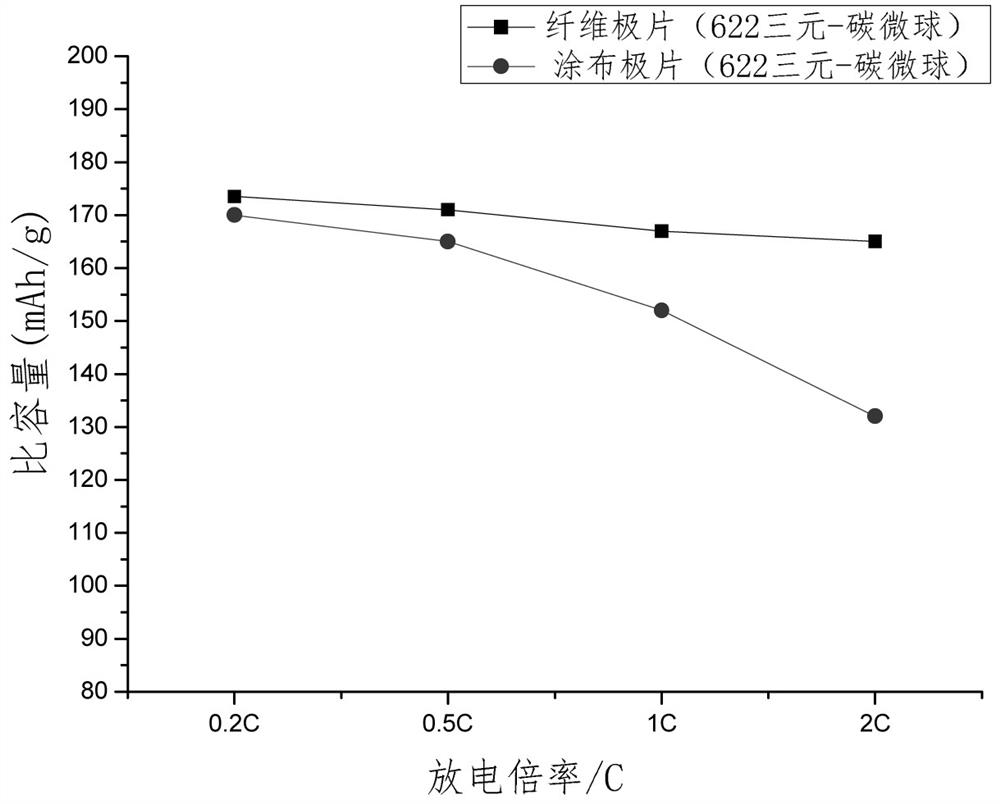

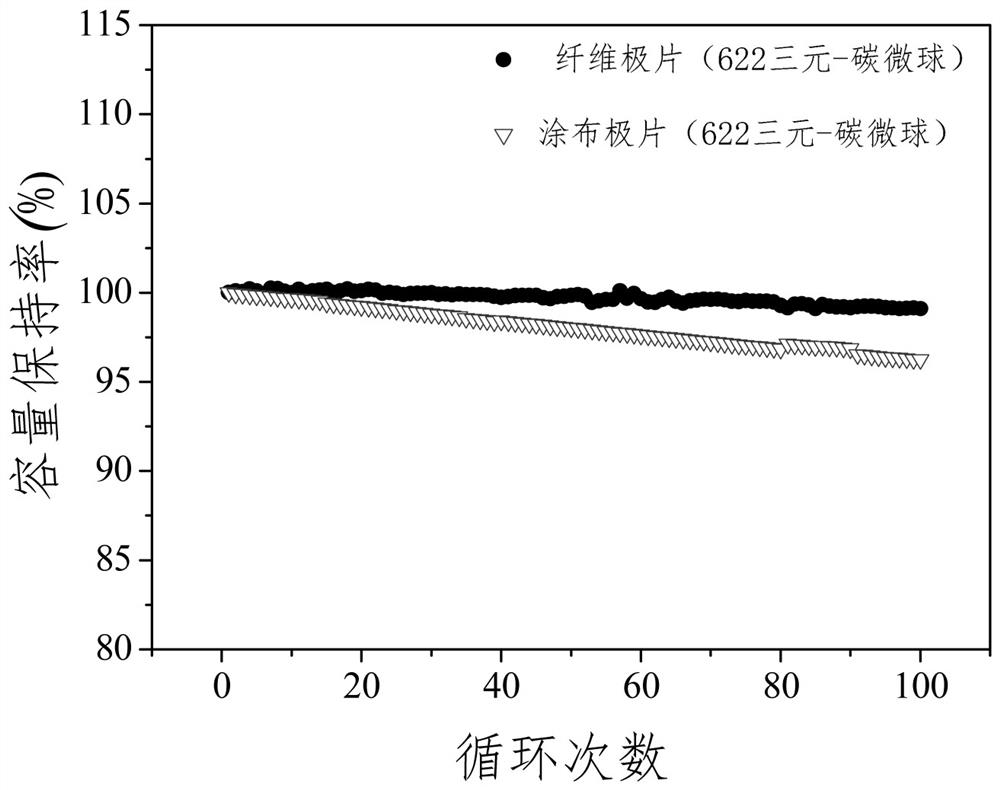

[0069] In addition, the wet coatin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com