High-strength crossover flange and processing technology thereof

A technology for converting flanges and processing technology, which is applied in the direction of flange connection, metal processing equipment, manufacturing tools, etc., and can solve the problems of increased wear of the converted flange, increased impact of the converted flange, and reduced sealing performance. Achieve the effects of avoiding continuous leakage, improving high-strength performance, and improving wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The invention provides a high-strength conversion flange, including steel material and cladding material, the weight of the cladding material is 100g, and the weight of the steel material is 10kg; the steel material is calculated according to the mass percentage of elements: C: 1.12 %, Si: 0.44%, Mn: 0.52%, Cr: 0.30%, Ni: 0.62%, Mo: 0.46%, Ga: 0.19%, Re: 0.025%, Zr: 0.016%, Lu: 0.032%, Sn: 0.24 %, P≤0.02%, S≤0.03%, and the balance is Fe; the coating material includes: 3.40g of acrylamide, 0.09g of vinylimidazole, 0.015g of ammonium persulfate, and 5.40g of graphene oxide , 6.40g of silver nitrate, 4.40g of glucose, 8.40g of nano-silicon dioxide, 5.80g of nano-yttrium oxide, 66.095g of deionized water;

[0032] The present invention also provides a processing technology for a high-strength conversion flange, and the specific processing steps are as follows:

[0033] Step 1: Weighing the above-mentioned steel material and acrylamide, vinylimidazole, ammonium persulfate, ...

Embodiment 2

[0046] The difference from Example 1 is that the weight of the cladding material is 100g, and the weight of the steel material is 20kg; the steel material includes: C: 1.56%, Si: 0.54%, Mn: 0.60%, Cr: 0.48%, Ni: 0.68%, Mo: 0.58%, Ga: 0.25%, Re: 0.035%, Zr: 0.022%, Lu: 0.048%, Sn: 0.32%, P≤0.02%, S≤0.03%, The balance is Fe; the coating material includes: 3.80g of acrylamide, 0.11g of vinylimidazole, 0.021g of ammonium persulfate, 7.20g of graphene oxide, 7.20g of silver nitrate, 6.20g of glucose, 9.20g of nano-silica, 6.40g of nano-yttrium oxide, and 59.869g of deionized water.

Embodiment 3

[0048] All different from Examples 1-2, the weight of the cladding material is 100g, and the weight of the steel material is 15kg; the weight ratio of the cladding material and the steel material is: 1:150; the steel material The material is calculated according to the mass percentage of elements, including: C: 1.34%, Si: 0.49%, Mn: 0.56%, Cr: 0.39%, Ni: 0.65%, Mo: 0.52%, Ga: 0.22%, Re: 0.030%, Zr: 0.019%, Lu: 0.040%, Sn: 0.28%, P≤0.02%, S≤0.03%, and the balance is Fe; the coating material includes: 3.60g of acrylamide, 0.10g of vinylimidazole, 0.018g ammonium persulfate, 6.30g of graphene oxide, 6.80g of silver nitrate, 5.30g of glucose, 8.80g of nano-silicon dioxide, 6.10g of nano-yttrium oxide, and 62.982g of deionized water.

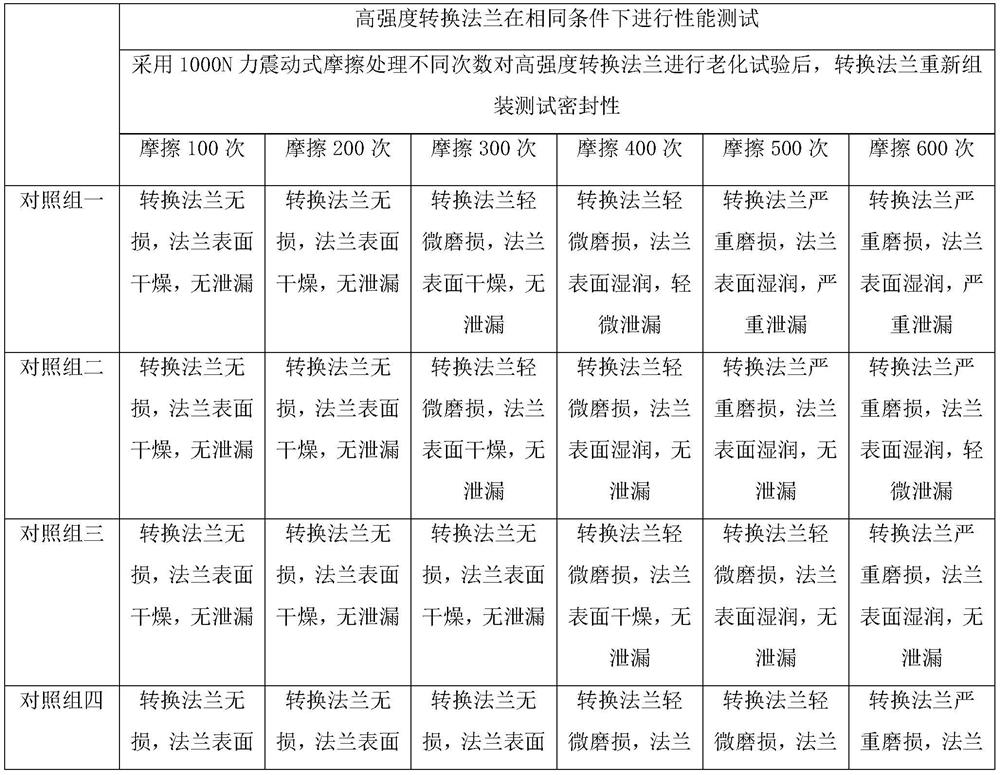

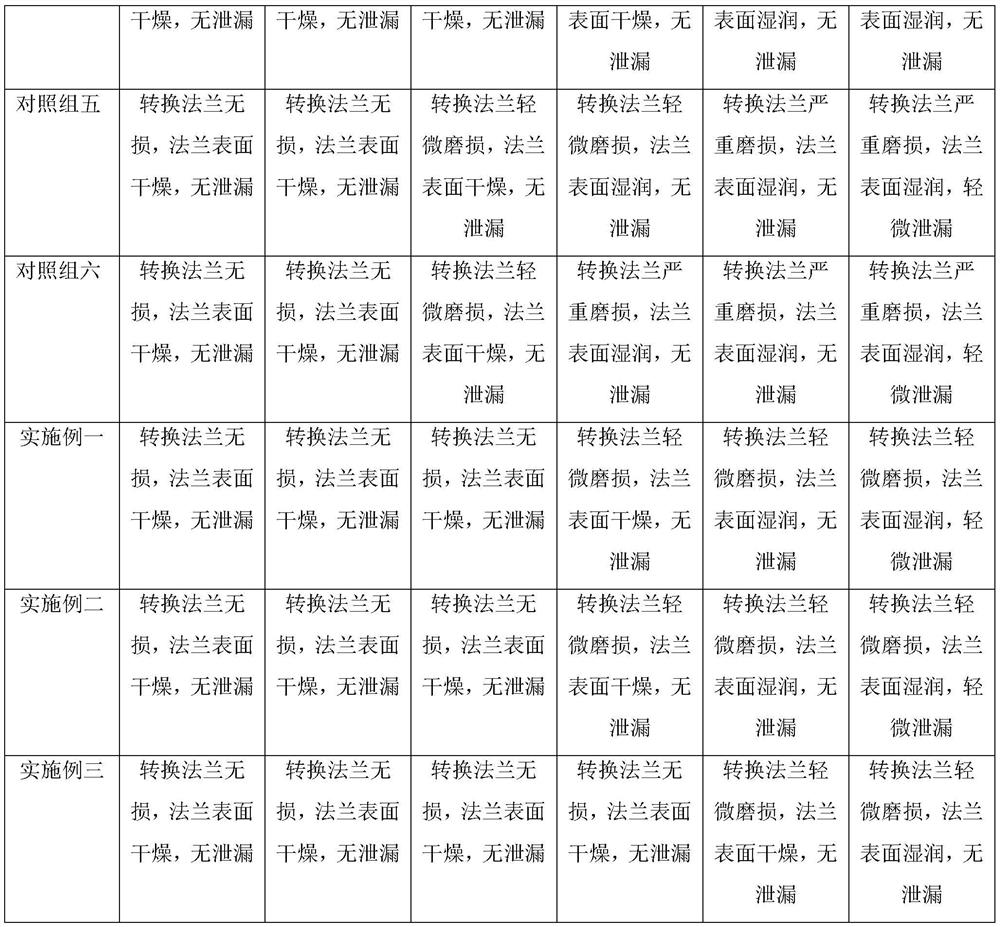

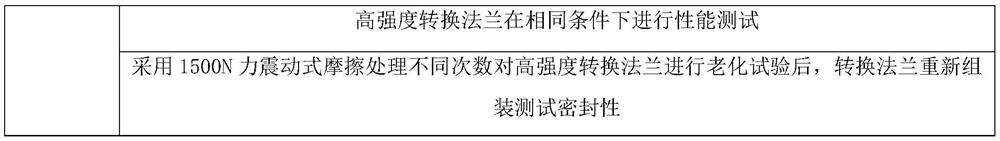

[0049] Get respectively the high-strength conversion flange made by above-mentioned embodiment 1-3 and the high-strength conversion flange of control group one, the high-strength conversion flange of control group two, the high-strength conversion fl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com