Oil-resistant and heat-resistant insulating material as well as preparation method and application thereof

A technology of insulating materials and raw materials, applied in the direction of insulators, organic insulators, plastic/resin/wax insulators, etc., can solve the problems of oil resistance, low hardness, and not easy to bend, etc., and achieve reduced damage, high mechanical strength, and increased crosslinking degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

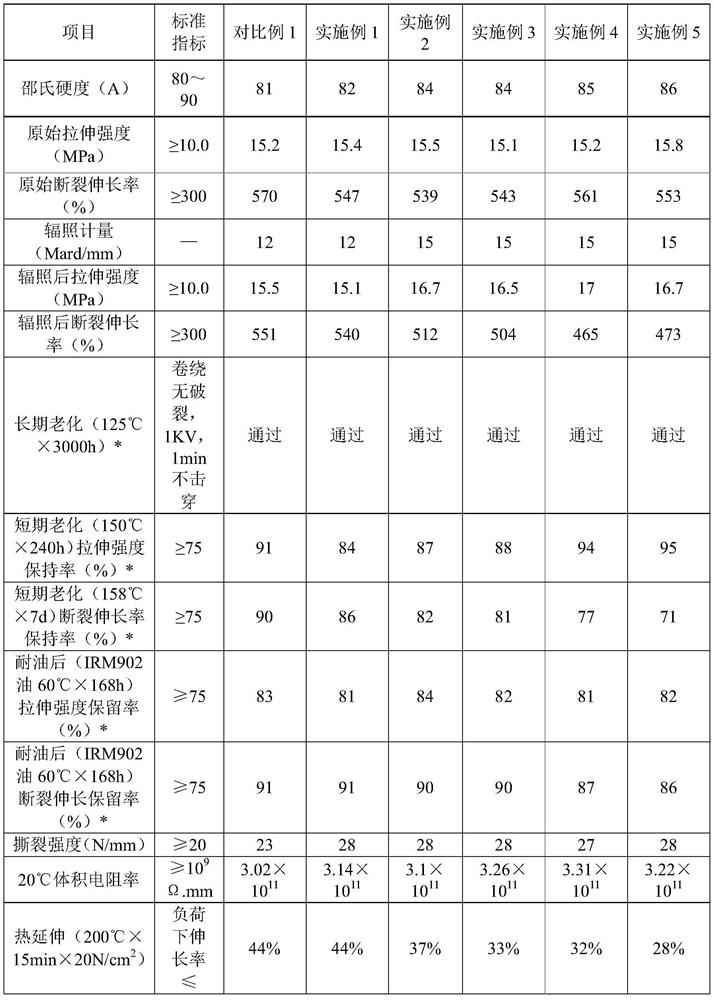

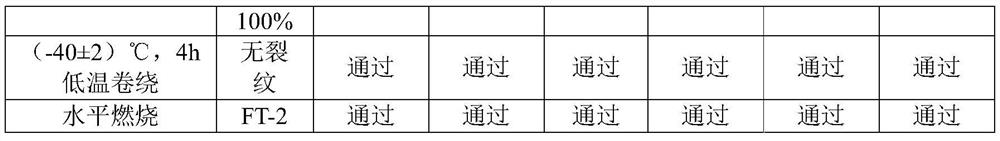

[0042] The technical solutions of the present invention will be further described below in conjunction with specific examples. The raw materials used in the following examples, unless otherwise specified, can be obtained from conventional commercial channels; the processes used, unless otherwise specified, are conventional processes in the art.

[0043] An oil-resistant and high-temperature-resistant cable insulation material, the composition of its preparation raw materials is shown in Table 1 below.

[0044] Table 1. Raw material composition of cable insulation material (mass percentage%)

[0045] Comparative example 1 Example 1 Example 2 Example 3 Example 4 Example 5 SEBS 34 34 34 33 32 30 LDPE 28 20 20 20 20 20 Metallocene LLDPE 0 8 8 8 8 8 ADP 15 15 15 15 15 15 MCA 15 15 15 15 15 15 MBSI-002P 2 2 2 2 2 2 TAIC 5.5 5.5 5.5 6.5 7.5 9 Anti-245 0.1 0.1 0.1 0.1 0.1 0.1 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com