Preparation method of graphene oxide loaded dopamine coated manganese dioxide nano composite structure electrode material

A manganese dioxide and nanocomposite technology, applied in battery electrodes, secondary batteries, structural parts, etc., can solve problems such as poor structural stability and low electrical conductivity, and achieve the effects of low cost, short production cycle and convenient post-processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

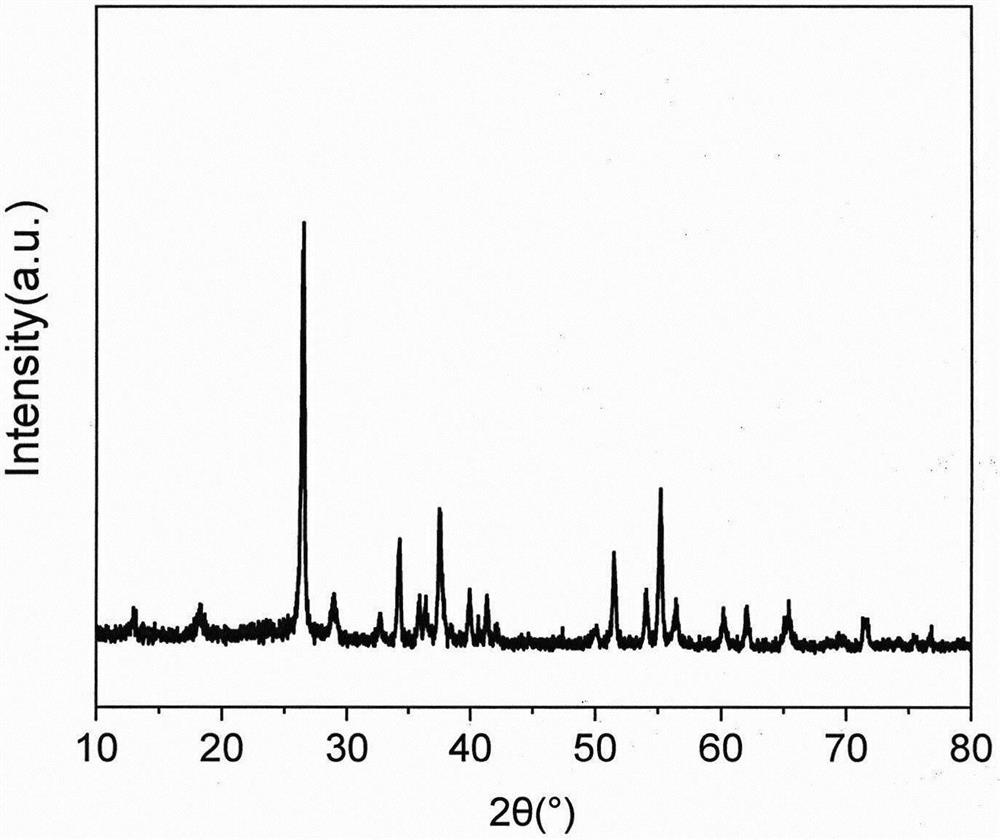

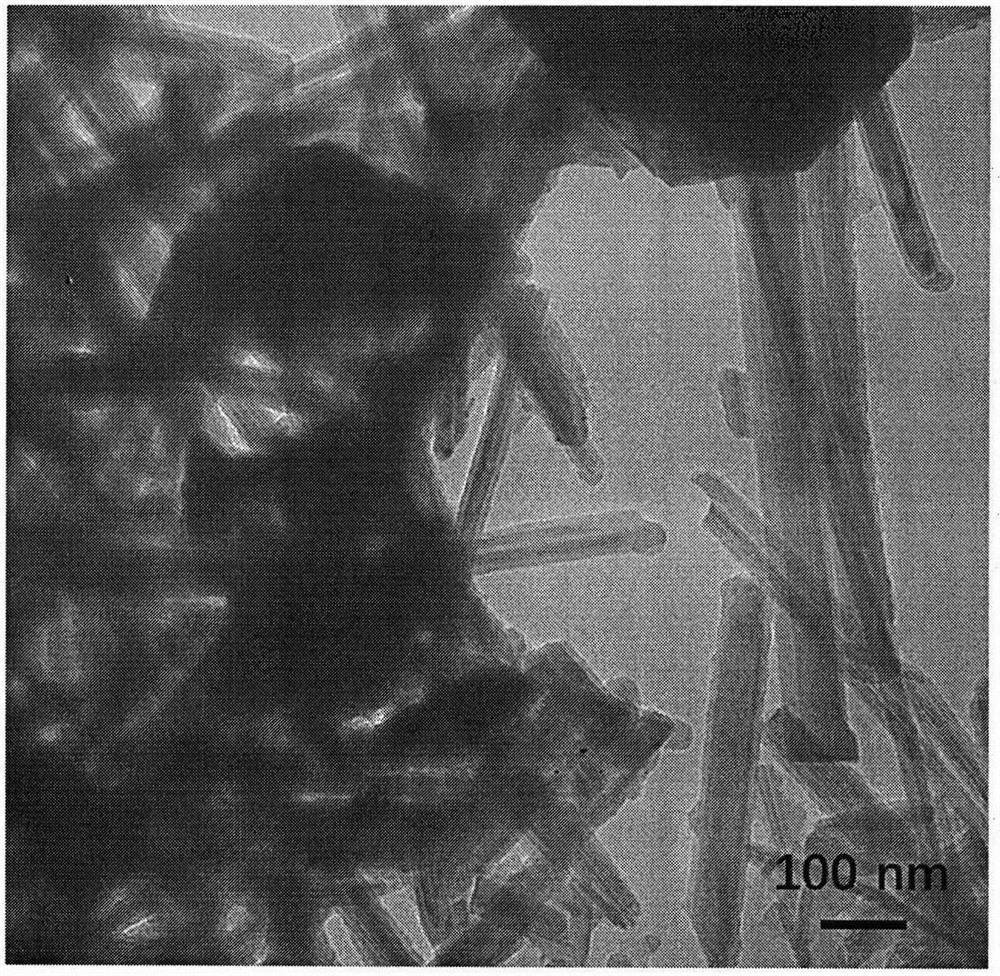

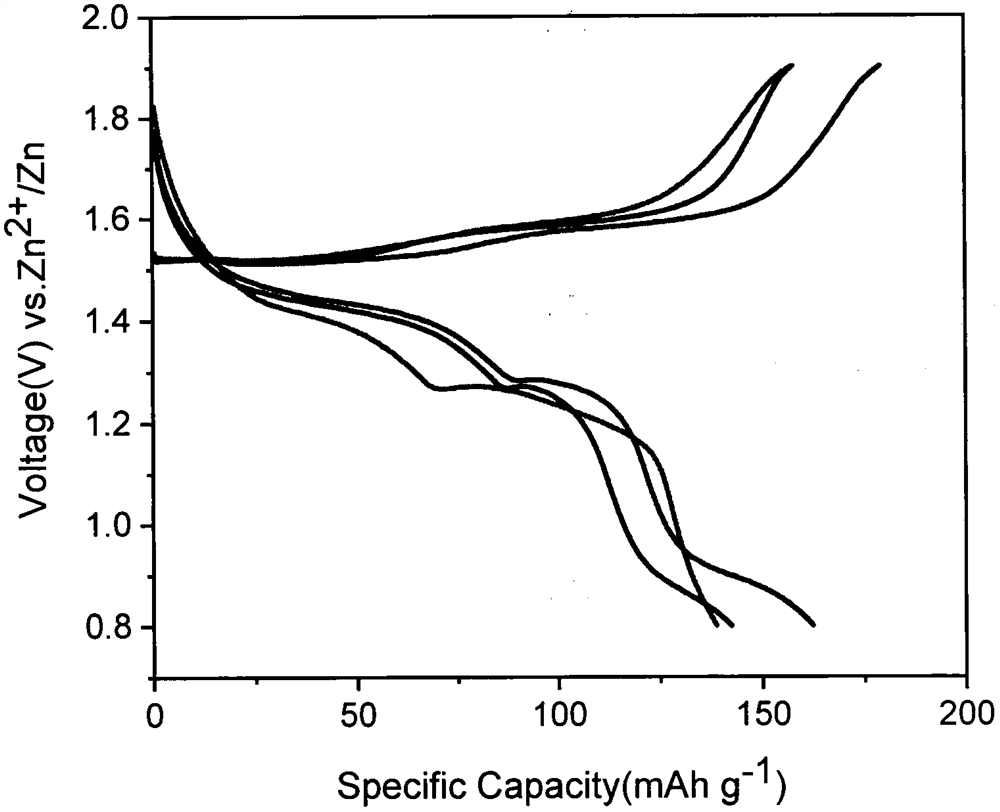

[0023] A preparation method of a graphene oxide-loaded dopamine-coated manganese dioxide nanocomposite structure electrode material, the steps are:

[0024] (1) Add 0.003mol / L, 270mL manganese sulfate solution into 0.2mol / L, 8mL dilute sulfuric acid aqueous solution, and stir well.

[0025] (2) 0.08mol / L, 60mL potassium permanganate aqueous solution, graphene oxide mass fraction is 1%, dispersant is 20mL deionized water, joins in the manganese sulfate solution respectively; The mixed solution is transferred to polytetrafluoroethylene The reaction was carried out at 140°C for 12 hours in the reactor.

[0026] (3) Place the initial product in a centrifuge, centrifuge at a speed of 8000r / min for 25min, repeatedly wash and centrifuge 3 times with deionized water, then dry the product completely in a freeze dryer to obtain manganese dioxide / oxidized Graphene composite.

[0027] (4) Add 0.08g of manganese dioxide / graphene oxide composite to the 100mL solution of polyethylene oxide...

Embodiment 2

[0030] (1) Add 0.008mol / L, 270mL manganese sulfate solution into 0.3mol / L, 8mL dilute sulfuric acid aqueous solution, and stir well.

[0031] (2) 0.1mol / L, 60mL potassium permanganate aqueous solution, graphene oxide mass fraction is 5%, dispersant is 20mL deionized water, ethanol, dimethylformamide mixture, join in the manganese sulfate solution respectively; The mixture was transferred to a polytetrafluoroethylene reactor and reacted at 160° C. for 9 h.

[0032] (3) Place the initial product in a centrifuge, centrifuge at a speed of 9500r / min for 20min, repeatedly wash and centrifuge 3 times with deionized water, then dry the product completely in a freeze dryer to obtain manganese dioxide / oxidized Graphene composite.

[0033] (4) 0.16g manganese dioxide / graphene oxide composite is added to the 200mL solution of polyethylene oxide-polypropylene oxide-polyethylene oxide with a dissolved mass fraction of 0.8%, and the added quality is 0.08g dopamine, stirred and then vacuum ...

Embodiment 3

[0036] (1) Add 0.01mol / L, 270mL manganese sulfate solution into 0.5mol / L, 8mL dilute sulfuric acid aqueous solution, and stir well.

[0037] (2) 0.2mol / L, 60mL potassium permanganate aqueous solution, graphene oxide mass fraction is 10%, dispersant is 20mL ethanol, dimethylformamide mixture; transfer the mixed solution to the polytetrafluoroethylene reaction kettle React at 180°C for 12h.

[0038] (3) Place the initial product in a centrifuge, centrifuge at a speed of 12000r / min for 10min, repeatedly wash and centrifuge 3 times with deionized water, then dry the product completely in a freeze dryer to obtain manganese dioxide / oxidized Graphene composite.

[0039] (4) 0.32g of manganese dioxide / graphene oxide composite is added to the 300mL solution of polyethylene oxide-polypropylene oxide-polyethylene oxide with a mass fraction of 1.2%, adding a mass of 0.32 g of dopamine, stirred and then vacuum filtered to obtain an intermediate product.

[0040] (5) The intermediate pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com