Method for detecting defects of die-cut product

A product defect and detection method technology, which is applied in the direction of optical testing of defects/defects, measuring devices, and material analysis through optical means, can solve the problems of low detection efficiency and detection stability, increase accuracy and improve detection efficiency , the effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Next, the technical solutions in the embodiments of the present invention will be described in connection with the drawings of the embodiments of the present invention, and it is understood that the described embodiments are merely the embodiments of the present invention, not all of the embodiments. Based on the embodiments of the present invention, all other embodiments obtained by those of ordinary skill in the art are in the range of the present invention without making creative labor premise.

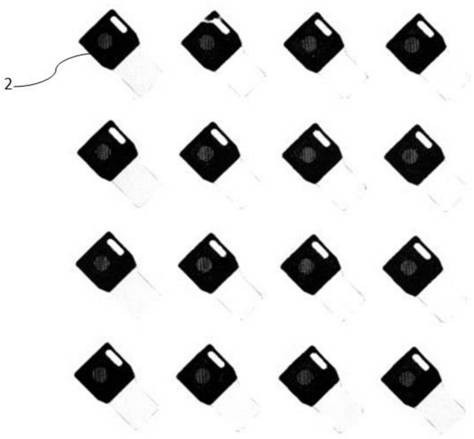

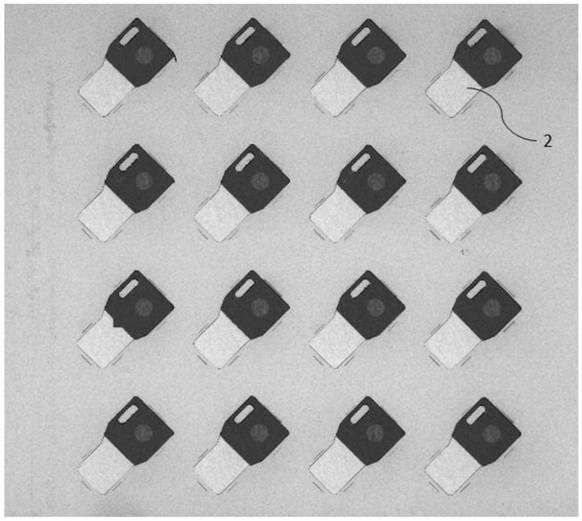

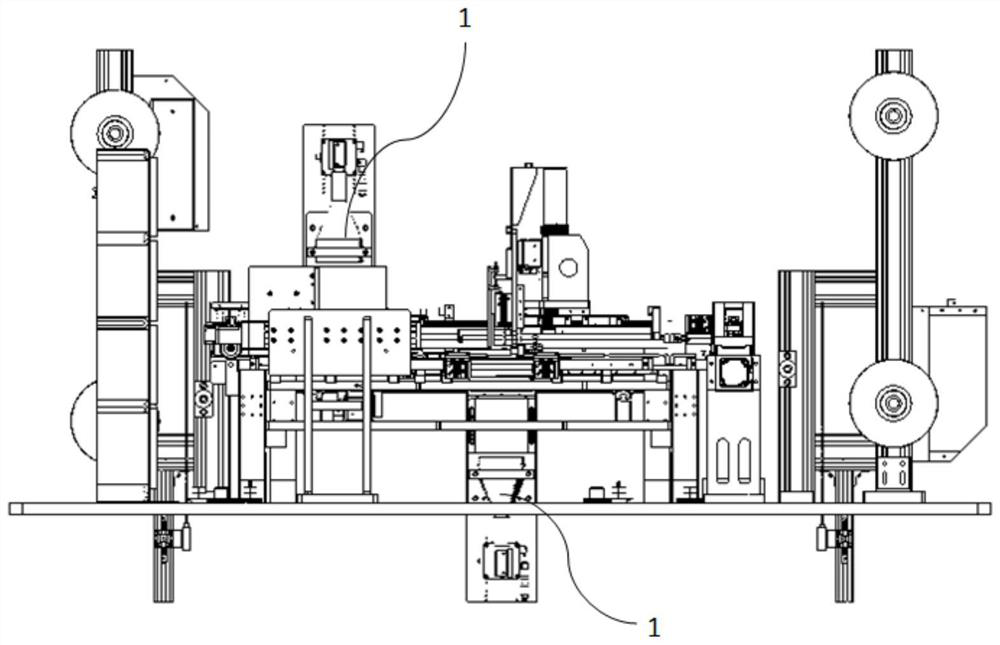

[0030] like Figure 1 to 5 As shown, the detection method of the die cut product of the present embodiment includes the following steps:

[0031] The original image information of the die cut product 2 is acquired using the optical station 1, which includes a surface array camera 11, a telephoto lens 12, and a light source unit 13 disposed toward the die cut product 2, the light source unit 13. Includes coaxial light far and annular light source 132 of mutual switching. Since the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com