Exposed waterproof coating with early rain resistance and preparation method thereof

A waterproof coating, exposed technology, applied in the direction of coating, can solve the problems of high material toxicity, high cost, poor market acceptance, etc., and achieve the effect of shortened drying time, good weather resistance and easy construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

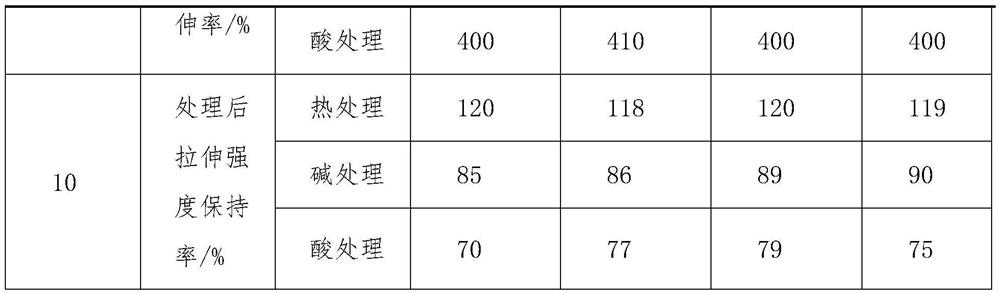

Examples

Embodiment 1

[0034] In the reaction kettle, 10 parts by mass of water, 0.4 parts by mass of substrate wetting agent, 0.4 parts by mass of dispersant 5040, 0.2 parts by mass of solvent-free silicon modified defoamer, 4 parts by mass of alkali Swelling thickener TT-935, 10 parts by mass of rutile titanium dioxide R-699, 25 parts by mass of 1250-mesh quartz powder, after the pigment and filler are added, it is preferable to grind with a grinder at a speed of 1500 rds / min. The grinding temperature is preferably 30-50° C.; the grinding temperature is preferably controlled by circulating cooling. After the uniformly dispersed slurry is prepared, the particle size of the resulting mixture is preferably ground to 40 μm. Add 1 mass part of ammonia water, add 65 mass parts of acrylic emulsion, add acrylic acid emulsion, add 0.1 mass part of carbodiimide crosslinking agent E-01, and disperse uniformly at high speed to prepare a one-component waterproof coating.

Embodiment 2

[0036] In the reaction kettle, 15 parts by mass of water, 0.4 parts by mass of substrate wetting agent, 0.4 parts by mass of dispersant 5027, 0.2 parts by mass of mineral oil modified defoamer, 6 parts by mass of polyurethane Thickener 1190, 15 parts by mass of rutile titanium dioxide R-699, 20 parts by mass of 1250-mesh quartz powder, after the pigment and filler are added, it is preferably ground with a grinder at a speed of 1500 rds / min. The grinding temperature is preferably 30-50° C.; the grinding temperature is preferably controlled by circulating cooling. After the uniformly dispersed slurry is prepared, the particle size of the resulting mixture is preferably ground to 40 μm. Add 2 parts by mass of ammonia water and 60 parts by mass of acrylic emulsion. After adding the acrylic emulsion, add 0.1 part by mass of carbodiimide crosslinking agent V-02-L2, and disperse uniformly at high speed to prepare a one-component waterproof coating.

Embodiment 3

[0038]In the reactor, 20 parts by mass of water, 0.4 parts by mass of substrate wetting agent, 0.4 parts by mass of dispersant 5027, 0.4 parts by mass of mineral oil modified defoamer, 5 parts by mass of polyurethane Thickener 8W, 10 parts by mass of rutile titanium dioxide R-699, 15 parts by mass of 1250-mesh ground calcium carbonate, 15 parts by mass of glass microspheres, after the pigment and filler are added, it is preferably ground with a grinder at a speed of 1500 rds / min. The grinding temperature is preferably 30-50° C.; the grinding temperature is preferably controlled by circulating cooling. After the uniformly dispersed slurry is prepared, the particle size of the resulting mixture is preferably ground to 40 μm. Add 1 mass part of ammonia water, add 60 mass parts of acrylic emulsion, add acrylic emulsion, add 0.1 mass part of carbodiimide crosslinking agent V-02-L2, and disperse uniformly at high speed to prepare a one-component waterproof coating.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| tack-free time | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com