Preparation method of fiber composite material

A technology of fiber composite materials and raw materials, applied in the field of composite materials, can solve problems such as material waste, environmental pollution, and refractory degradation, and achieve the effects of cost reduction, good bonding effect, and easy decomposition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

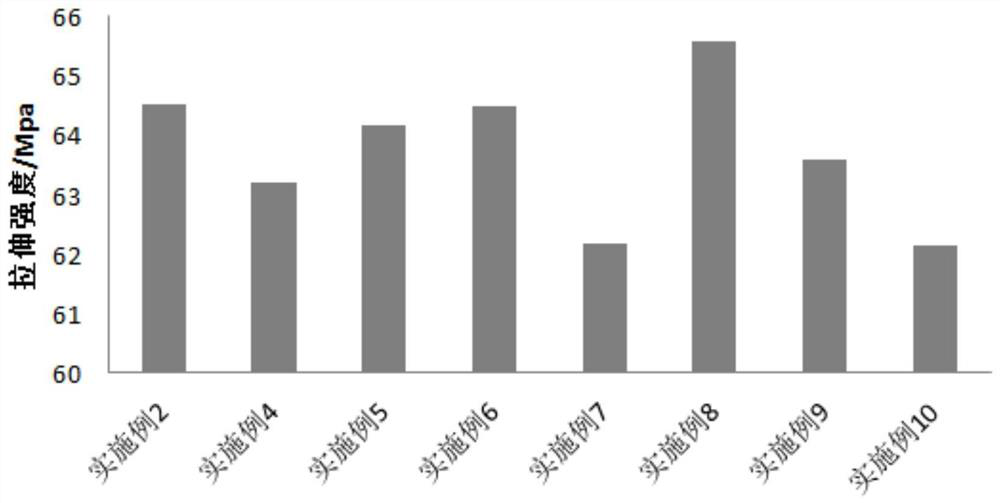

Examples

preparation example Construction

[0023] The invention provides a method for preparing a fiber composite material, which comprises the following steps: after pulverizing the woody raw material, steaming at 85-100°C for 130-150 minutes, taking out the steamed woody raw material, and pre-processing it through a mixed enzyme solution treatment to obtain enzyme-treated products; add sodium hydroxide solution to the enzyme-treated products and soak for 20-28 hours, then rinse until neutral, and dry to obtain alkali-treated products; dilute the silane coupling agent in absolute ethanol, add Alkali-treated products, mixed, and then dried to obtain the first treated product; the first treated product, base material, antioxidant and lubricant were weighed in proportion, added to a twin-screw extruder, and heated at 170-220 ° C, Perform high-temperature kneading at 60-80 r / min to obtain a blend; after the blend is crushed, injection molding is performed, and the fiber composite material is obtained after cooling and demo...

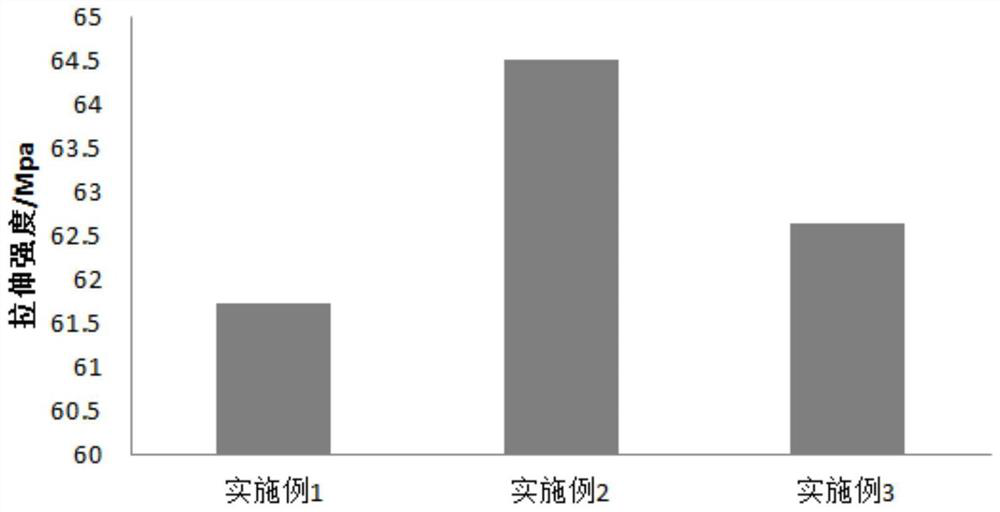

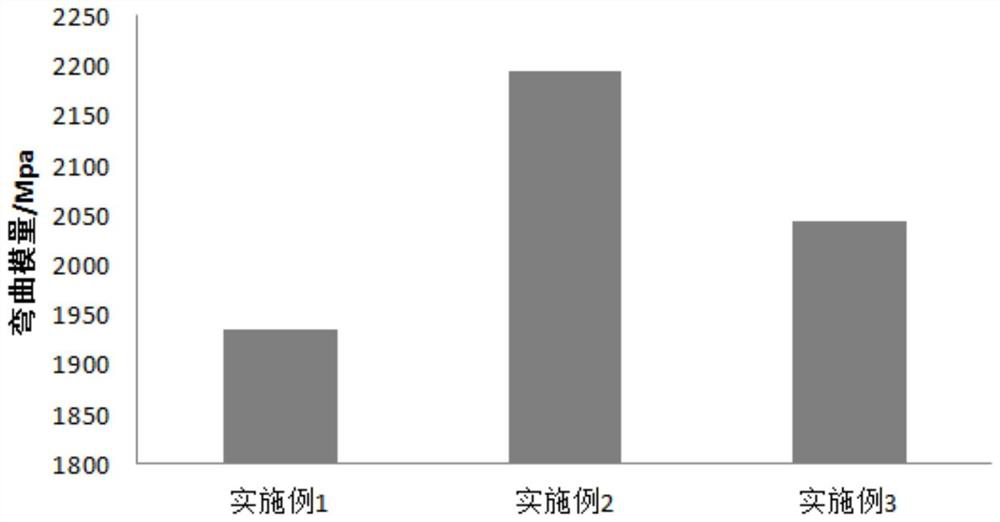

Embodiment 1

[0036] A method for preparing a fiber composite material, comprising the steps of:

[0037] After pulverizing the agave to 40 μm, steam it at 85°C for 130 minutes,

[0038]Mix pectin lyase and xylanase at a mass ratio of 0.1:1.5 to prepare a mixed enzyme solution with a concentration of 30%, and mix the steamed agave with the mixed enzyme solution at a mass ratio of 1:2 , soaked at 45°C for 5h, washed and dried at 35°C to obtain the enzyme-treated product;

[0039] The enzyme-treated product is soaked in a 5% sodium hydroxide solution for 20 hours, rinsed until neutral, and dried at 35°C to obtain the alkali-treated product;

[0040] Weigh KH550 and the alkali-treated product according to the mass ratio of KH550 and alkali-treated product 0.3:1, add the silane coupling agent to 8 mass times of absolute ethanol to dilute, add the alkali-treated product, and mix at 900r / min for 20min , and then dried at 70°C for 100 minutes to obtain the first processed product;

[0041] Acco...

Embodiment 2

[0044] A method for preparing a fiber composite material, comprising the steps of:

[0045] After the agave is crushed to 50 μm, it is steamed at 90°C for 140 minutes,

[0046] Mix pectin lyase and xylanase at a mass ratio of 0.3:1.7 to prepare a mixed enzyme solution with a concentration of 35%, and mix the steamed agave with the mixed enzyme solution at a mass ratio of 1:2.5 , soaked at 50°C for 7h, washed and dried at 40°C to obtain the enzyme-treated product;

[0047] The enzyme-treated product is soaked in 8% sodium hydroxide solution for 24 hours, rinsed until neutral, and dried at 40°C to obtain the alkali-treated product;

[0048] Weigh KH550 and the alkali-treated product according to the mass ratio of KH550 and alkali-treated product 0.6:1, add KH550 to 9 mass times of absolute ethanol to dilute, add the alkali-treated product, mix at 1100r / min for 23min, and then place Dry at 75°C for 120 minutes to obtain the first processed product;

[0049] According to the ma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com