Manufacturing method for paper buffer type board with bidirectional corrugated structure sandwich layer

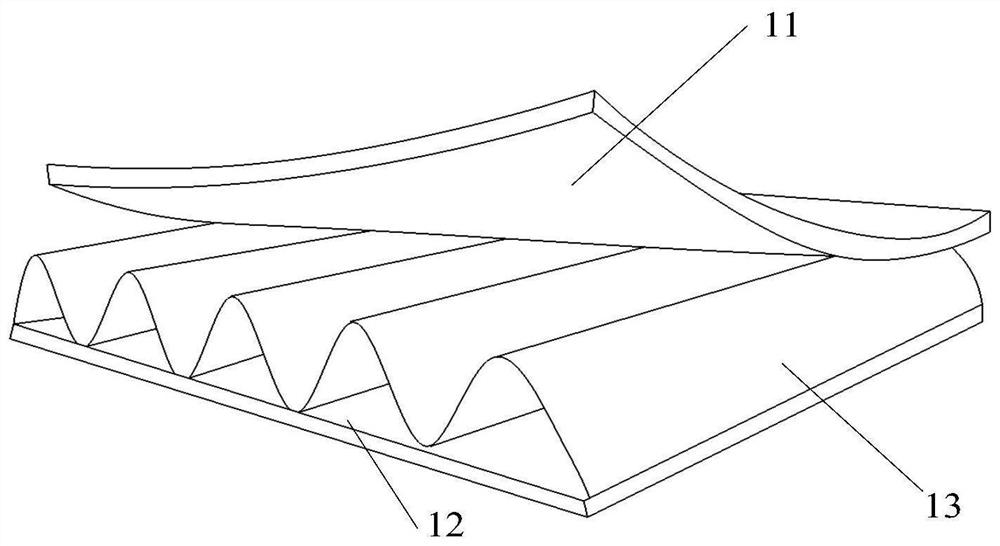

A manufacturing method and sandwich layer technology, applied in the direction of mechanical processing/deformation, etc., can solve the problems of limited corrugated height, difficult processing, large amount of glue used for forming and bonding, etc., and achieve good stability and synchronization of mechanical properties The effect of lifting and small consumption of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

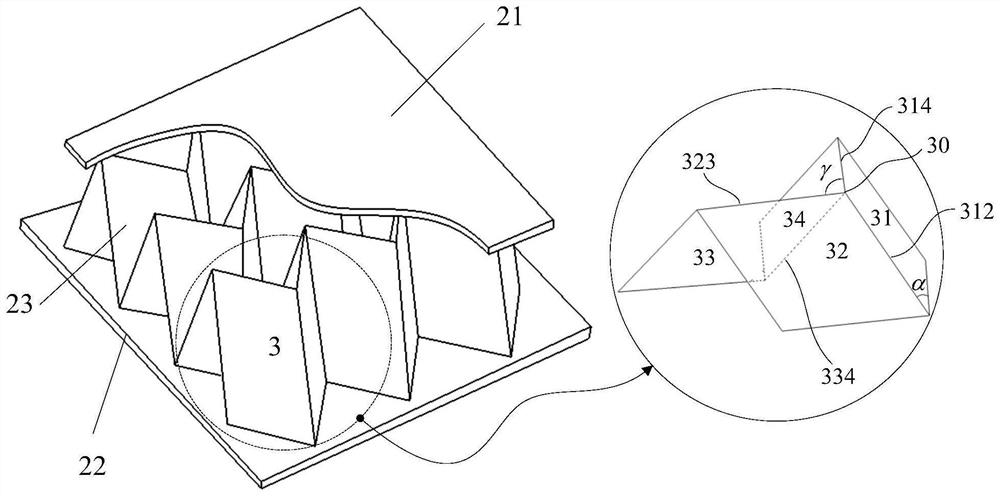

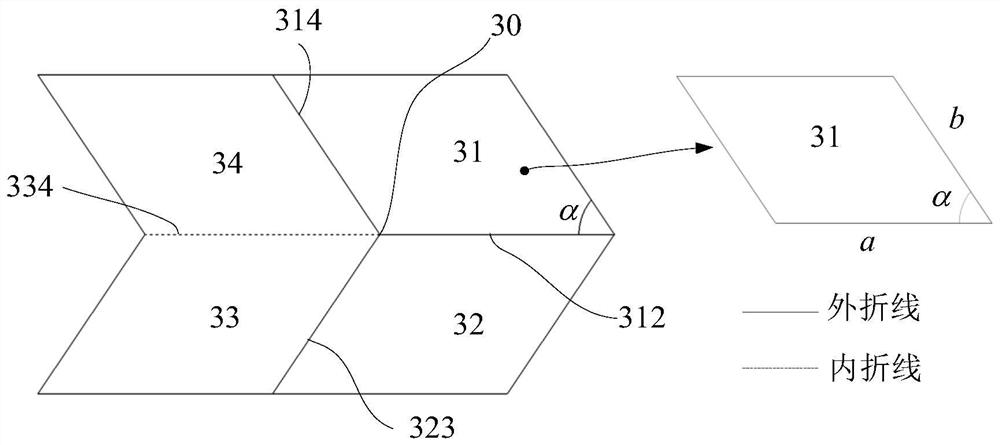

[0074] The selected quantitative is 170g / m 2 Kraft paper as the upper and lower panels, the basis weight is 170g / m 2 Corrugated paper is used as the material for the sandwich layer; the sandwich layer is topologically formed by the first type of cell three-dimensional structure with the following basic structural characteristics: the cell three-dimensional structure is composed of four parallelogram plates with the same geometric parameters, and the two sides of the parallelogram have the same length is 10mm, the angle Δ between the two sides is 60°, and the folding angle γ is 80°, which is recorded as sample 1#. The thickness of sample 1# is 7.99mm.

Embodiment 2

[0076] The selected quantitative is 170g / m 2 Kraft paper as the upper and lower panels, the basis weight is 170g / m 2 Corrugated paper is used as the material for the sandwich layer; the sandwich layer is topologically formed by the second type of cell three-dimensional structure with the following basic structural characteristics: the cell three-dimensional structure is composed of four parallelogram plates with the same geometric parameters, and the lengths of the two sides of the parallelogram are respectively It is a=10mm, b=20mm, the angle Δ between the two sides is 60°, and the folding angle γ is 80°, which is recorded as sample 2#. The thickness of sample 2# is 7.99mm.

Embodiment 3

[0078] The selected quantitative is 170g / m 2 Kraft paper as the upper and lower panels, the basis weight is 170g / m 2 Corrugated paper is used as the material for the sandwich layer; the sandwich layer is topologically formed by the third type of cell three-dimensional structure with the following basic structural characteristics: the cell three-dimensional structure is composed of four parallelogram plates with the same geometric parameters, and the lengths of the two sides of the parallelogram are respectively It is a=20mm, b=10mm, the angle Δ between the two sides is 60°, and the folding angle γ is 80°, which is recorded as sample 3#. The thickness of sample 3# is 16.00mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com