Shielding layer manufactured by copper-clad plate

A technology of shielding layer and copper clad laminate, which is applied in the fields of magnetic field/electric field shielding, transformer/inductance parts, prevention/reduction of unnecessary electric/magnetic influence, etc. Complexity and other issues, to achieve the effect of simple docking process, simple processing and flexible design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to make the object, technical solution and advantages of the present invention more clear and definite, the present invention will be further described in detail below with reference to the accompanying drawings and examples.

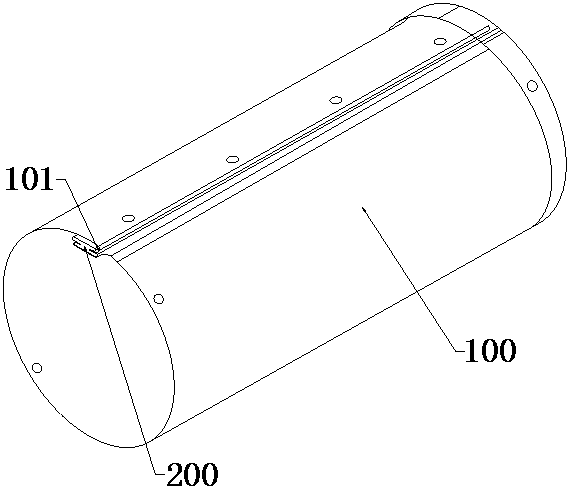

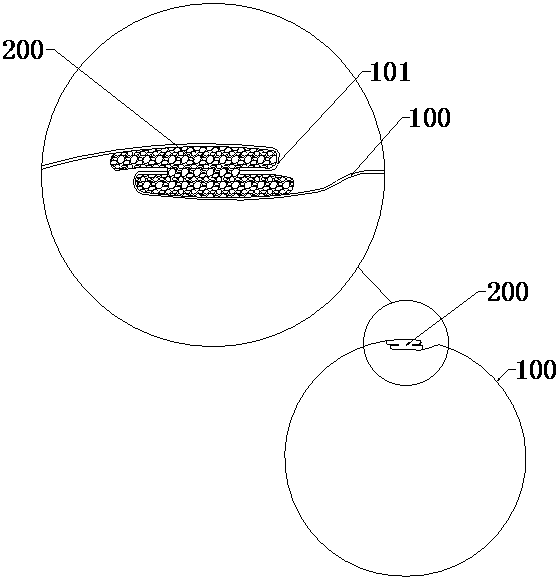

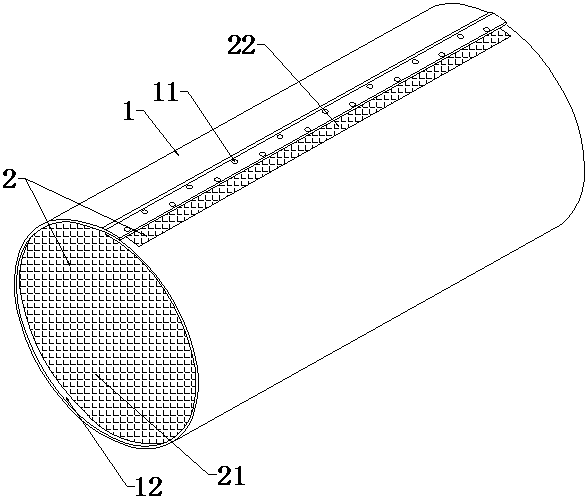

[0022] Such as figure 1 and 2 As shown, the existing electrical coupling partition between the high and low voltage packages of the transformer generally uses copper sheets as the partition layer, and when the copper sheet 100 is rolled into a cylindrical shape, the joint surfaces at both ends must be fully wound into a circle but It is also required to be non-conductive (required to be separated by an insulator), so the processing is more difficult; so by setting the hook pieces 101 at both ends of the copper sheet, the hook pieces 101 are buckled on the insulating strip 200, so that the two ends of the copper sheet 100 There is no contact between the ends, so a loop will not be formed; meanwhile, it is necessary to add an insulating l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com