Preparation process of flame-retardant hand-tearing cloth adhesive tape

A preparation process, a technology of hand-tearing cloth, applied in the direction of flame-retardant fibers, adhesives, textile materials, etc., can solve the problems of cloth tape burning and dripping, and achieve the effect of ensuring the molding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

[0017] The present invention provides to achieve the above purpose and solve the problem of dripping when the cloth tape is burned in the prior art. The present invention provides the following technical solutions:

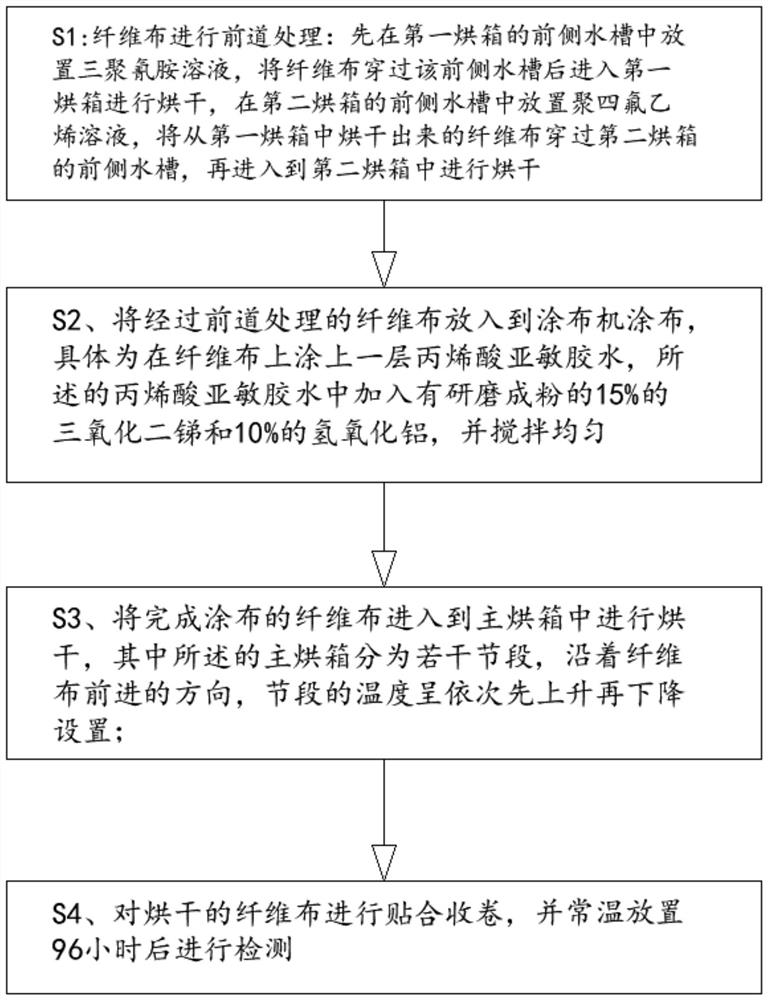

[0018] Such as figure 1 Shown, provide a kind of preparation technology of flame-retardant hand-tear cloth adhesive tape, comprise the following steps:

[0019] S1, the fiber cloth is subjected to the previous treatment: firstly, the melamine solution is placed in the front water tank of the first oven, and the fiber cloth is passed through the front water tank and then enters the first oven for drying. The water solubility is relatively poor, so it is necessary to heat the water in the water tank on the front side of the first oven to 75-80°C, grind the melamine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com