All-composite-carbon-fiber magnetic pump

A composite carbon fiber and magnetic pump technology, applied in pumps, pump devices, non-variable pumps, etc., can solve problems such as damage, negative effects of magnetic pumps, abrasive isolation sleeves, etc., to prolong life, reduce abrasion, reduce vortex The effect of current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

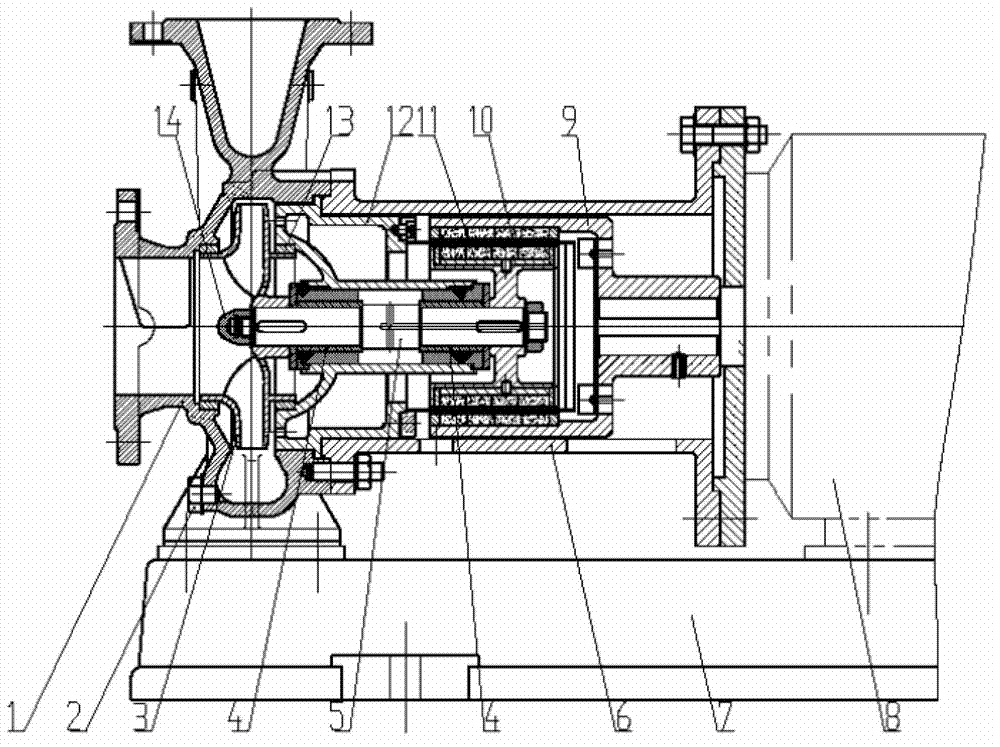

[0013] figure 1 It is a structural schematic diagram of the full-composite carbon fiber magnetic pump of the present invention. The full-composite carbon fiber magnetic pump includes a pump body 1, an impeller 3, a screw plug 2, a pump shaft 5, a sliding bearing 4, a connecting frame 6, a pump base 7, and an inner magnetic rotor 8. Outer magnetic rotor 9, inner rotor 11, spacer sleeve 10, bearing body 12, mouth ring 13, impeller nut 14. The impeller 3 is installed in the pump body 1,

[0014] The full-composite carbon fiber magnetic pump of the present invention includes a base part, a power part, a pump body part, and a transmission part; it is characterized in that: the pump shaft 5 and the inner magnetic rotor 8 are wrapped by a full-composite carbon fiber isolation sleeve 10 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com