Preparation method and application of conductive gel material

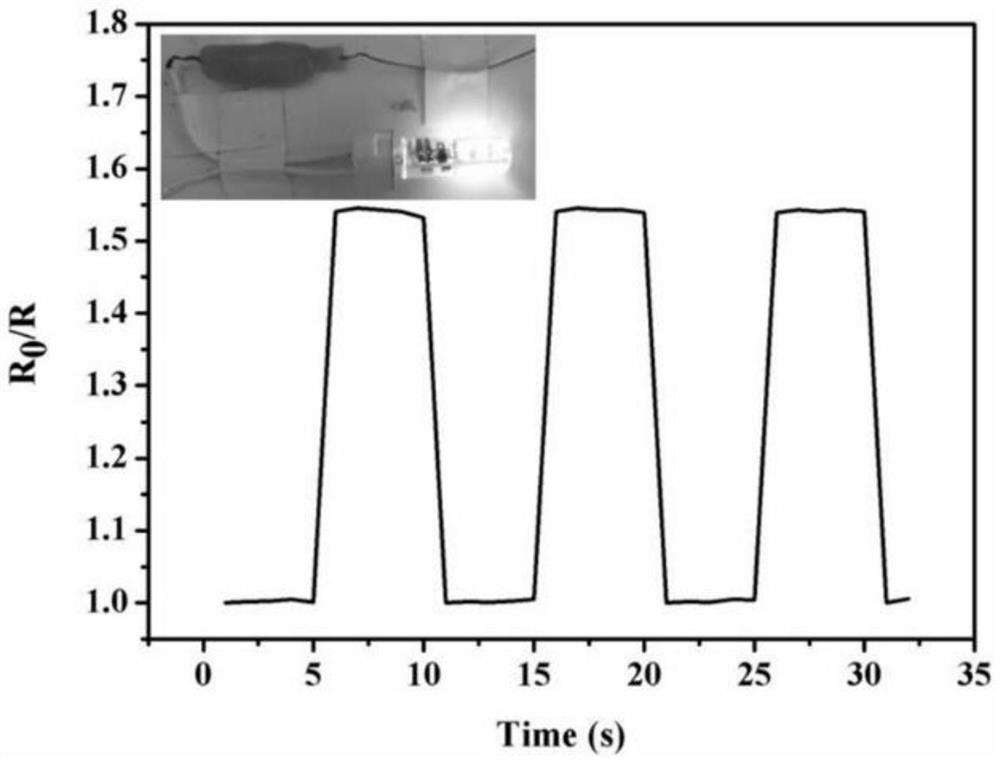

A technology of conductive gel and surfactant, applied in the field of preparation of conductive gel materials, can solve the problems of lack of self-healing ability, limitation, poor biocompatibility and high toxicity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] The invention provides a kind of preparation method of conductive gel material, comprises the following steps:

[0033] (1) Dissolve β-D-mannuronic acid and α-L-guluronic acid at a mass ratio of 1:1, add concentrated sulfuric acid and react at 80°C to obtain polymer A;

[0034] (1) mixing polyvinyl butyral butyral, polymer A, sodium carbonate, natural polymer and water to obtain a conductive precursor solution;

[0035] (2) Mixing the aqueous surfactant solution and the conductive precursor solution, and performing precooling treatment and freeze-thaw cycle treatment on the mixture in turn to obtain a conductive gel material;

[0036] The surfactant is an anionic surfactant.

[0037] The invention mixes polyvinyl butyral butyral, β-D-mannuronic acid, sodium carbonate, natural high polymer and water to obtain a conductive precursor solution. In the present invention, the mass ratio of the polyvinyl butyral butyral to the polymer A is preferably 2-10:1, more preferably ...

Embodiment 1

[0051] (1) Dissolve β-D-mannuronic acid and α-L-guluronic acid at a mass ratio of 1:1, add concentrated sulfuric acid and react at 80°C to obtain polymer A;

[0052] (2) Preparation of conductive precursor solution:

[0053] Add the mixture of polyvinyl butyral and polymer A to deionized water, wherein the ratio of the mixture of polyvinyl butyral and polymer A to deionized water is 1.0g:10mL, polyvinyl butyral and The mass ratio of polymer A is 2:1. After mixing evenly, put it in a magnetic stirrer at 90°C, and then add sodium carboxymethyl cellulose (CMC -Na), wherein the ratio of carboxymethylcellulose sodium (CMC-Na) and polyvinyl butyral to polymer A mixed solution is 0.01g: 10mL, stirred for 1h until completely dissolved to obtain a conductive precursor solution;

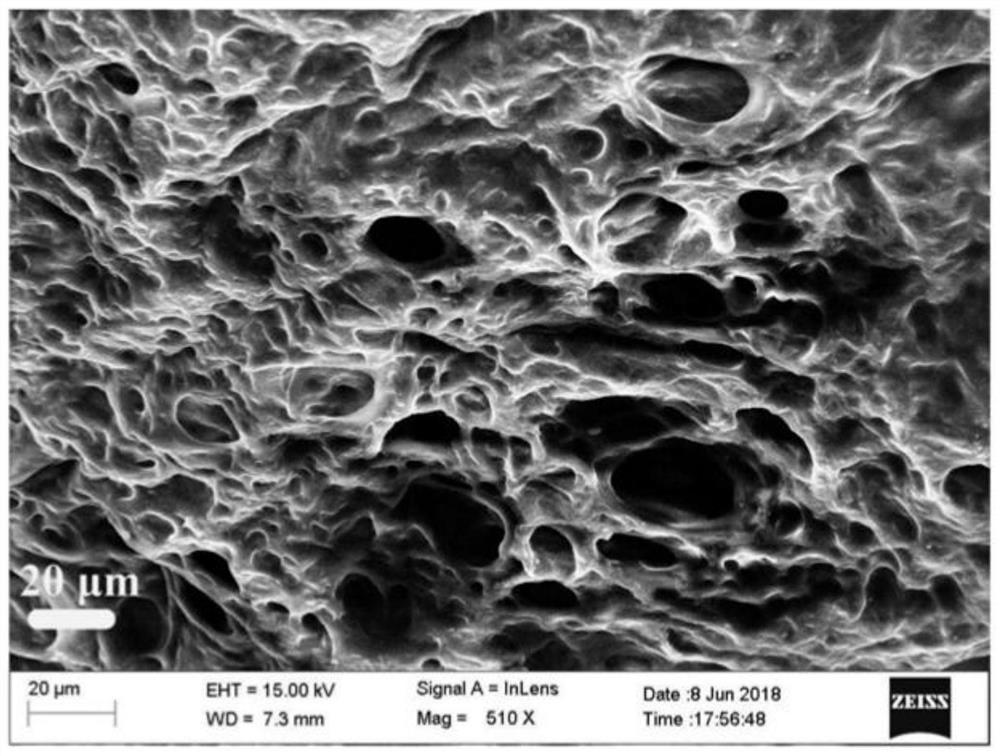

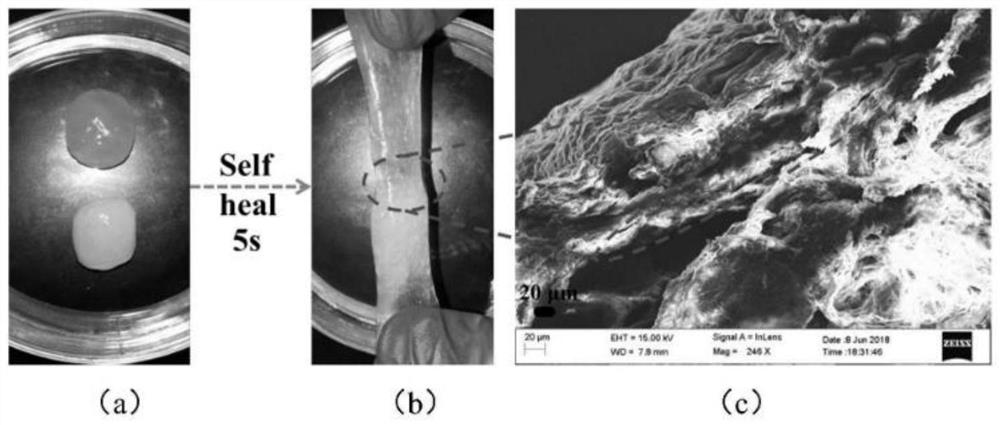

[0054] (3) Preparation of self-healing degradable porous conductive gel material:

[0055] Firstly, a sodium dodecylbenzenesulfonate aqueous solution with a concentration of 0.02g / mL was prepared, and then t...

Embodiment 2

[0063] (1) Dissolve β-D-mannuronic acid and α-L-guluronic acid at a mass ratio of 1:1, add concentrated sulfuric acid and react at 80°C to obtain polymer A;

[0064] (2) Preparation of conductive precursor solution

[0065] Add the mixture of polyvinyl butyral and polymer A to deionized water, wherein the ratio of the mixture of polyvinyl butyral and polymer A to deionized water is 1.2g:10mL, polyvinyl butyral and The mass ratio of polymer A is 4:1. After mixing evenly, place it in a magnetic stirrer at 92°C, and then add soluble starch to the above mixed solution of polyvinyl butyral and polymer A, wherein soluble starch and The ratio of the mixed solution of polyvinyl butyral and polymer A is 0.02g:10mL, stirred for 1.5h until completely dissolved to obtain a conductive precursor solution;

[0066] (3) Preparation of self-healing degradable porous conductive gel materials

[0067] First prepare the aqueous solution of sodium α-alkenyl sulfonate with a concentration of 0.04...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com