Thermoplastic polyethylene glycol-based phase change energy storage material as well as preparation method and application thereof

A phase change energy storage material, polyethylene glycol-based technology, applied in heat exchange materials, energy storage, chemical instruments and methods, etc. The problems of complicated methods, etc., achieve the effect of good recyclability, unlimited storage period and good dielectric constant.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

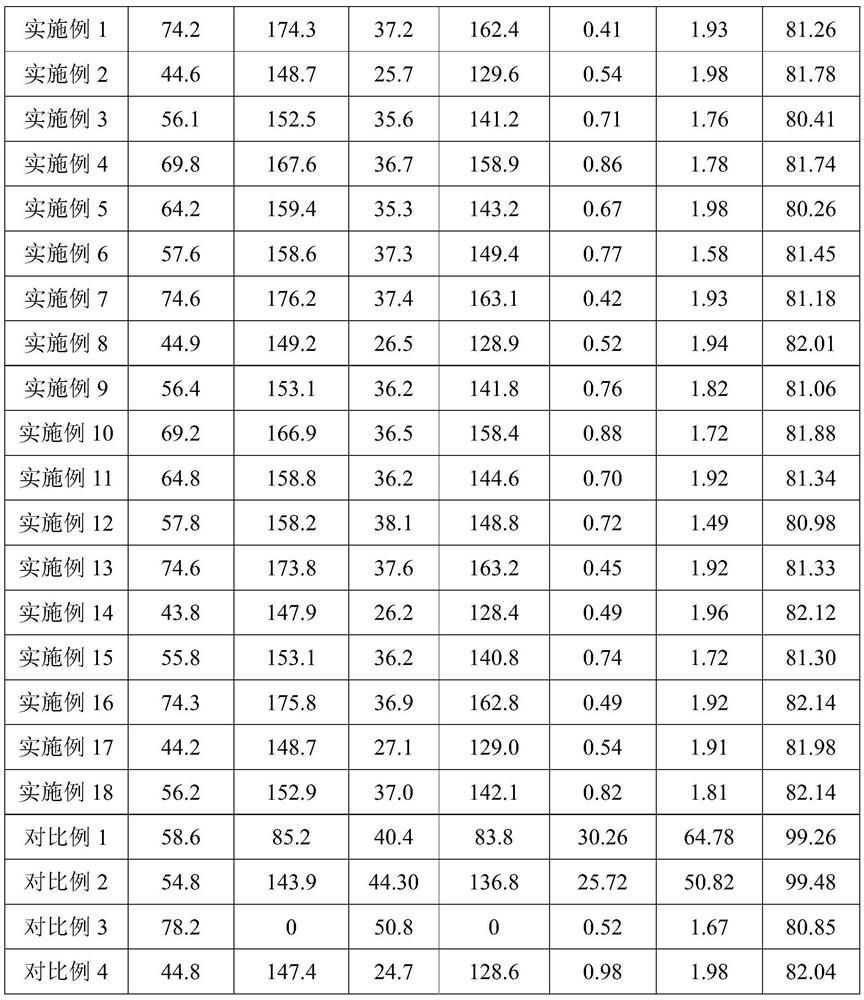

Embodiment 1

[0030] 70g average molecular weight is 10000 polyethylene glycol monoacrylate, 3g photoinitiator 1-hydroxycyclohexyl phenyl ketone (Irgacure-184), 0g or 1g nano boron nitride dispersion liquid is added 30g average molecular weight is 200 In the methoxypolyethylene glycol monomethacrylate, stir evenly, then pour the above precursor into the mold, and cure it under the ultraviolet light with a wavelength of 365nm and a power of 1kW for 2min to obtain photocurable polyethylene glycol based phase change energy storage materials. The boron nitride particle size in the nano boron nitride dispersion liquid is 200nm, the dispersed phase is polyethylene glycol with a molecular weight of 200, and the mass concentration of the dispersion liquid is 5%. The thermal conductivity of the samples prepared in this example was tested, and it was found that compared with the product without nano thermal conductive filler dispersion (addition amount: 0g), after adding nano thermal conductive fille...

Embodiment 2

[0032]90g of polyethylene glycol monomethacrylate with an average molecular weight of 2000, 0g or 1g of photoinitiator 2-hydroxyl-2-methyl-1-phenylacetone (Irgacure-1173), 5g of nano-aluminum nitride were dispersed Add the solution to 10g of polyethylene glycol monoacrylate with an average molecular weight of 1000, stir evenly, then pour the above precursor into the mold, and cure it under LED light with a wavelength of 320nm and a power of 10W for 5min to obtain photocurable polyethylene glycol. Diol-based phase change energy storage materials. The aluminum nitride particle size in the nano-aluminum nitride dispersion liquid is 100nm, the dispersed phase is polyethylene glycol with a molecular weight of 600, and the mass concentration of the dispersion liquid is 20%. The thermal conductivity of the sample prepared in this embodiment was tested, and it was found that the thermal conductivity of the prepared material was increased by 12.4 times after adding the dispersion liqui...

Embodiment 3

[0034] 80g of polyethylene glycol monoacrylate with an average molecular mass of 3000, 2g of photoinitiator 2-methyl-2-(4-morpholinyl)-1-[4-(methylthio)phenyl]-1 - Acetone (Irgacure-907), 0g or 1g nanometer graphene oxide dispersion liquid is added in the methoxypolyethylene glycol monoacrylate of 20g average molecular weights 600, stir well, then above-mentioned precursor is poured in the mould, in Curing under ultraviolet light with a wavelength of 305nm and a power of 5kW for 2 minutes can obtain a photocurable polyethylene glycol-based phase-change energy storage material. The graphene oxide particle size in the nanometer graphene oxide dispersion is 20nm, the dispersed phase is polyethylene glycol with a molecular weight of 800, and the mass concentration of the dispersion is 30%. The thermal conductivity of the sample prepared in this embodiment was tested, and it was found that the thermal conductivity of the prepared material increased by 13.8 times after adding the di...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com