Macromolecular moisture-proof blocking agent and preparation method thereof

A polymer and plugging agent technology, applied in the field of plugging agents, can solve the problems of the plugging agent’s moisture-proof sealing performance and bonding performance, and reduce the protection effect of production and operation equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] A preparation method of a polymer moisture-proof sealing agent, comprising the following steps:

[0031] Mix polyphenylene sulfide and carbon fiber, add vinyl acetate, add oxidant in an inert gas atmosphere, adjust the pH to 4-5, stir at 500-550r / min for 40-50min, then rinse with water for 3-5 times, in Dry at 80-90°C to obtain modified polyphenylene sulfide; add silicone rubber, modified epoxy acrylate resin and dimethyl silicone oil to the modified polyphenylene sulfide, and react at 400-450°C for 2-4 hours, During the reaction process, magnetic stirring is used at a stirring speed of 1000-1100r / min, stirring once every 10-15min, stirring for 5-10min each time, and then concentrated under reduced pressure at 0.01-0.05MPa for 30-40min to obtain a polymer moisture-proof plugging agent.

[0032] The toughness, brittleness and medium viscosity of polyphenylene sulfide can be changed by modifying polyphenylene sulfide with carbon fiber and vinyl acetate. Because vinyl ac...

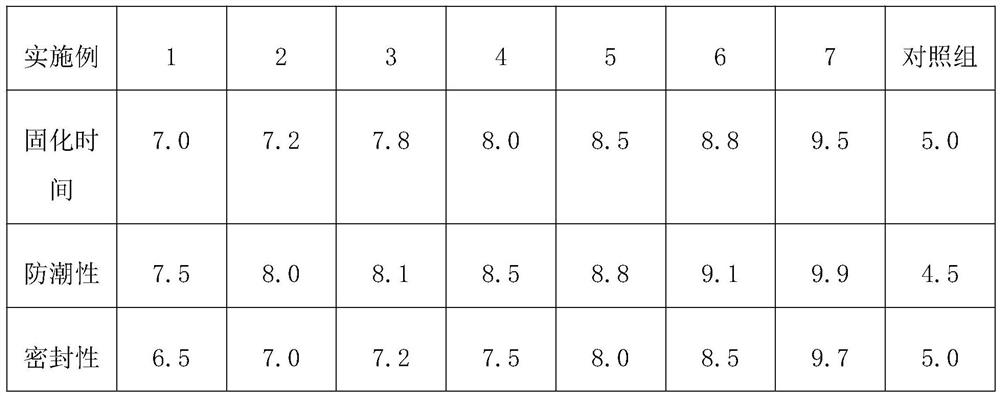

Embodiment 1

[0037] A polymer moisture-proof sealing agent, including the following raw materials: 10g of silicone rubber, 15g of polyphenylene sulfide, 5g of vinyl acetate, 3g of carbon fiber, 10g of modified epoxy acrylate resin and 20g of simethicone.

[0038] A preparation method of a polymer moisture-proof sealing agent, comprising the following steps:

[0039] Mix polyphenylene sulfide and carbon fiber, add vinyl acetate, add an oxidant in an inert gas atmosphere, adjust the pH to 4, and stir at 500r / min for 40min to obtain modified polyphenylene sulfide; Add silicone rubber, modified epoxy acrylate resin and simethicone oil, react at 400°C for 2 hours, and then concentrate under reduced pressure to obtain a polymer moisture-proof sealing agent.

Embodiment 2

[0041] A polymer moisture-proof sealing agent, including the following raw materials: 30g silicone rubber, 40g polyphenylene sulfide, 15g vinyl acetate, 12g carbon fiber, 20g modified epoxy acrylate resin and 40g simethicone oil.

[0042] A preparation method of a polymer moisture-proof sealing agent, comprising the following steps:

[0043] Mix polyphenylene sulfide and carbon fiber, add vinyl acetate, add an oxidant in an inert gas atmosphere, adjust the pH to 5, and stir at 550r / min for 50min to obtain modified polyphenylene sulfide; Add silicone rubber, modified epoxy acrylate resin and simethicone oil, react at 450°C for 4 hours, and then concentrate under reduced pressure to obtain a polymer moisture-proof sealing agent.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com