Quick-curing polyisocyanate composition as well as preparation method and application thereof

A technology of polyisocyanate and hydrogenated xylylene isocyanate is applied in the field of fast-curing polyisocyanate composition and preparation thereof, and can solve the problems of difficulty in achieving cyclic synergy, limited weather resistance and operating viscosity, poor quick drying, and the like, Achieve the effects of improved mechanical properties, fast curing molding speed, and good weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

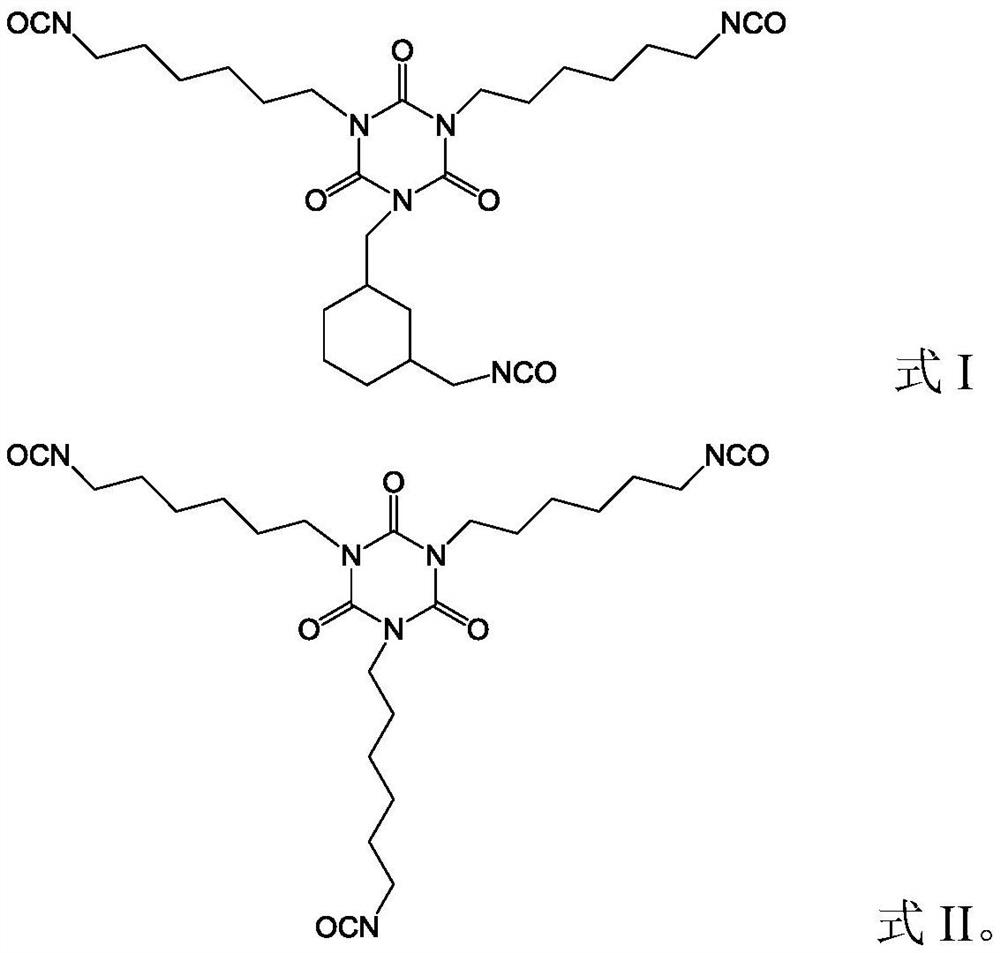

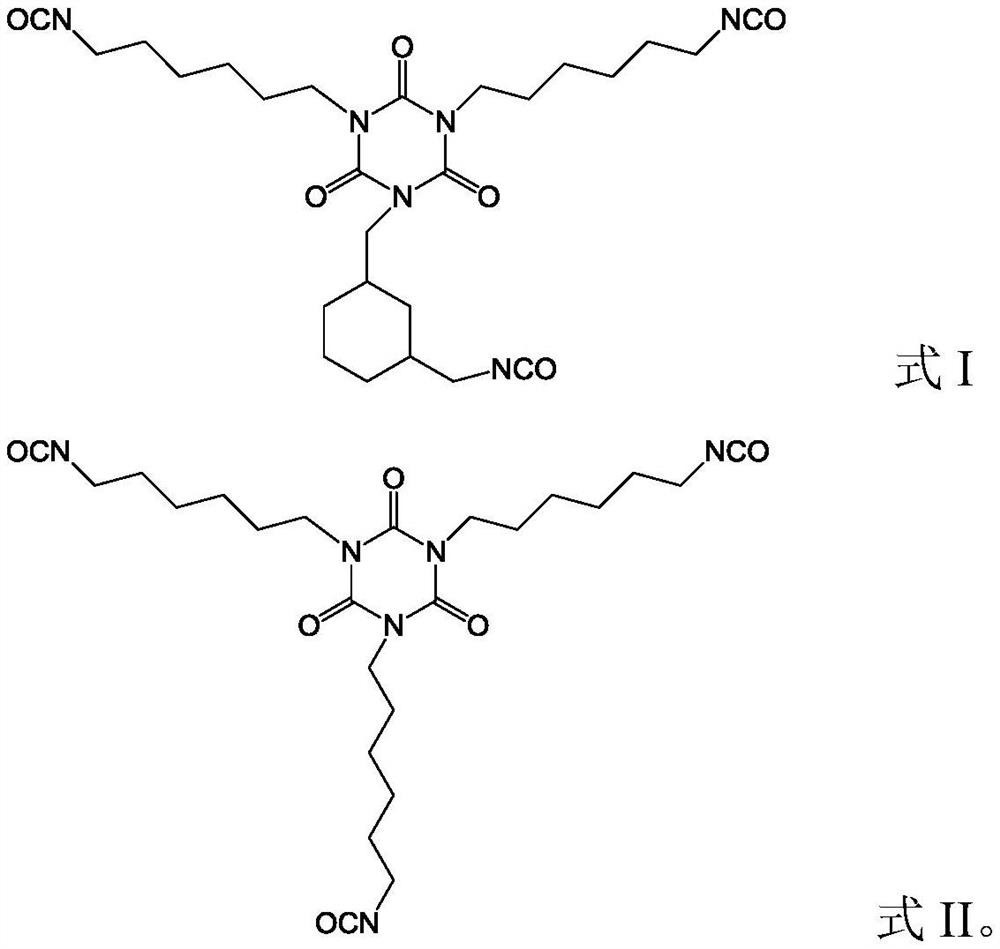

Method used

Image

Examples

Embodiment 1

[0101] (1) Under an inert gas atmosphere, 500 g of hexamethylene diisocyanate (HDI) was first added to the reaction vessel and the temperature was raised to 75° C., and then about 0.20 g of tetrabutylammonium hydroxide was added for trimerization.

[0102] (2) Test When the conversion rate reaches 23%, add 226g of hydrogenated xylylene diisocyanate (HXDI), and continue the trimerization reaction under the action of a catalyst until the conversion rate of isocyanurate reaches 45%, add 0.13 g of dibutyl phosphate terminated the reaction to obtain an isocyanate mixture solution.

[0103] (3) Further remove unreacted HDI and HXDI by distillation, namely multi-isocyanate composition 1#.

Embodiment 2-6

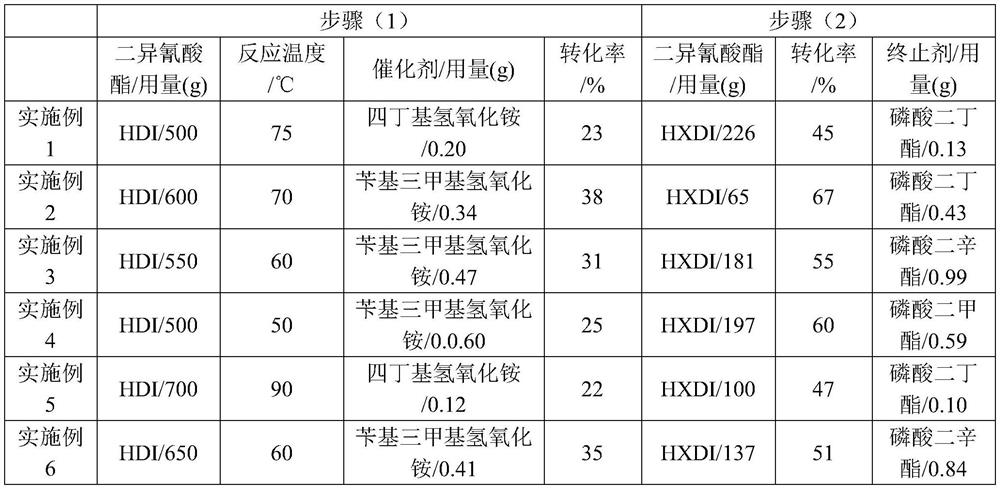

[0105] The polyisocyanate composition in Example 2-6 was prepared with reference to the method substantially the same as Example 1, the only difference being that the process conditions in Table 1 were different. The compositions prepared in each example are respectively referred to as polyisocyanate compositions 1#-6#.

[0106] Different processing conditions in table 1, each embodiment

[0107]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com