Ploroglucinol polyether carboxylate and composition and preparation method thereof, and viscosity reducing and efficiency improving method for CO2 flooding of deep low-permeability thickened oil

A phloroglucinol polyether carboxylate and a preparation method are applied in the directions of carboxylate preparation, drilling compositions, chemical instruments and methods, and can solve the problem of poor injectability of oil displacement chemicals and synergistic viscosity reduction. The problems of low efficiency and low viscosity reduction rate of heavy oil can improve the dissolution rate, facilitate transportation, and reduce the viscosity of heavy oil.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

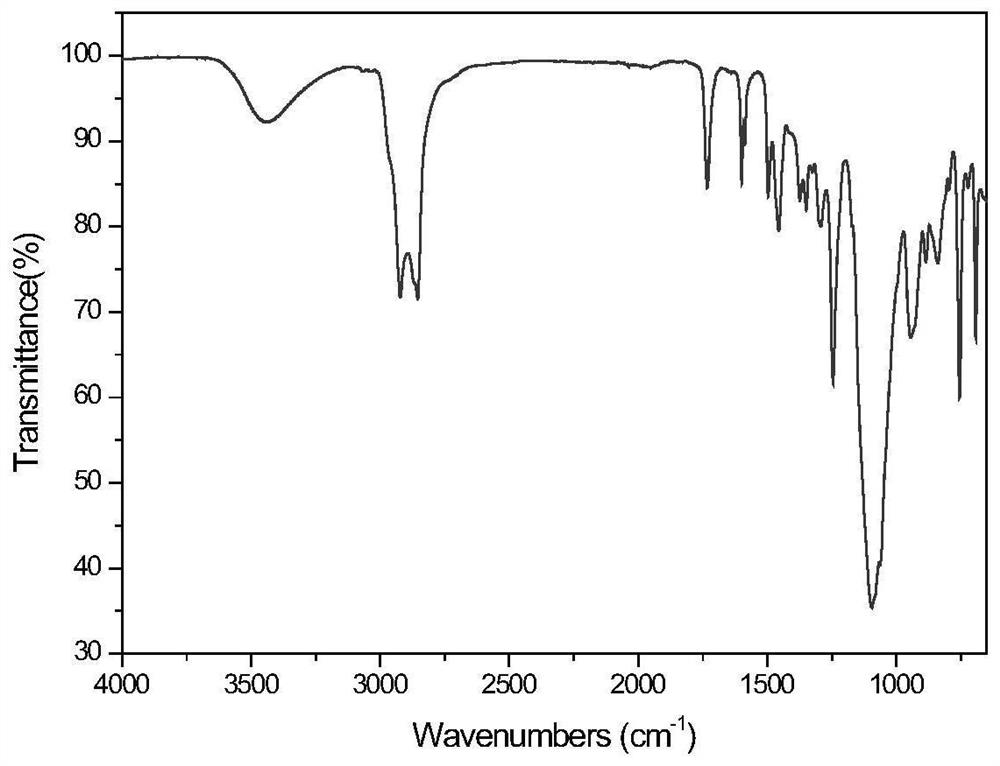

[0070] (a) preparation of phloroglucinol polyether carboxylate:

[0071] 1. Add 126g of anhydrous phloroglucinol (1mol), 4.6g of potassium hydroxide in the pressure reactor, and remove the air in the reaction flask by vacuum. N 2 Under protection, the system was heated to 120° C., and 264 g (6 mol) of ethylene oxide was slowly introduced to control the pressure to ≤0.10 MPa. After the reaction was completed, the temperature was lowered to 90° C., the low boilers were removed under reduced pressure, neutralized and dehydrated after cooling to obtain 372.1 g of phloroglucinol polyoxyethylene (n=6) ether, with a yield of 95.4%.

[0072] ② Add 195 g (0.5 mol) phloroglucinol polyoxyethylene (n=6) ether, 140 g (0.7 mol) lauric acid, and 2.5 g sodium bicarbonate to the dry reactor, and remove oxygen in a vacuum. in N 2 Under protection, the system was heated to 215°C and reacted for 2h. After cooling, it was neutralized and dehydrated to obtain 308.9 g of phloroglucinol polyoxyet...

Embodiment 2

[0078] (a) preparation of phloroglucinol polyether carboxylate:

[0079] 1. Add 126g of anhydrous phloroglucinol (1mol), 4.6g of potassium hydroxide in the pressure reactor, and remove the air in the reaction flask by vacuum. N 2Under protection, the system was heated to 120° C., and 348 g (6 mol) of propylene oxide was slowly introduced to control the pressure to ≤0.20 MPa. After the reaction was completed, the temperature was lowered to 90° C., the low boilers were removed under reduced pressure, neutralized and dehydrated after cooling to obtain 460.3 g of phloroglucinol polyoxypropylene (n=6) ether, with a yield of 97.1%.

[0080] ②Add 237g (0.5mol) phloroglucinol polyoxypropylene (n=6) ether, 100g (0.5mol) lauric acid, and 2.5g sodium bicarbonate to the dry reactor, and remove oxygen in vacuum. in N 2 Under protection, the system was heated to 215°C and reacted for 2h. After cooling, it was neutralized and dehydrated to obtain 321.4 g of phloroglucinol polyoxypropylen...

Embodiment 3

[0086] (a) preparation of phloroglucinol polyether carboxylate:

[0087] 1. Add 126g of anhydrous phloroglucinol (1mol), 4.6g of potassium hydroxide in the pressure reactor, and remove the air in the reaction flask by vacuum. N 2 Under protection, the system was heated to 120° C., and 432 g (6 mol) of butylene oxide was slowly introduced to control the pressure to ≤0.20 MPa. After the reaction, the temperature was lowered to 90° C., the low boilers were removed under reduced pressure, neutralized and dehydrated after cooling to obtain 523.4 g of phloroglucinol polyoxybutylene (n=6) ether, with a yield of 93.8%.

[0088] ②Add 279g (0.5mol) phloroglucinol polyoxybutylene (n=6) ether, 80g (0.4mol) lauric acid, and 2.5g sodium bicarbonate to the dry reactor, and remove oxygen in vacuum. in N 2 Under protection, the system was heated to 215°C and reacted for 2h. After cooling, it was neutralized and dehydrated to obtain 344.4 g of phloroglucinol polyoxybutylene (n=6) ether laur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com