Insulator for low-temperature construction of asphalt pavement road roller and method for preparing same

An asphalt pavement and release agent technology, applied in climate change adaptation, coating, etc., can solve problems such as non-compliance with energy saving and environmental protection, unfavorable construction, etc., achieve excellent antifreeze effect, reduce CO2 greenhouse gas emissions, and reduce fuel consumption. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

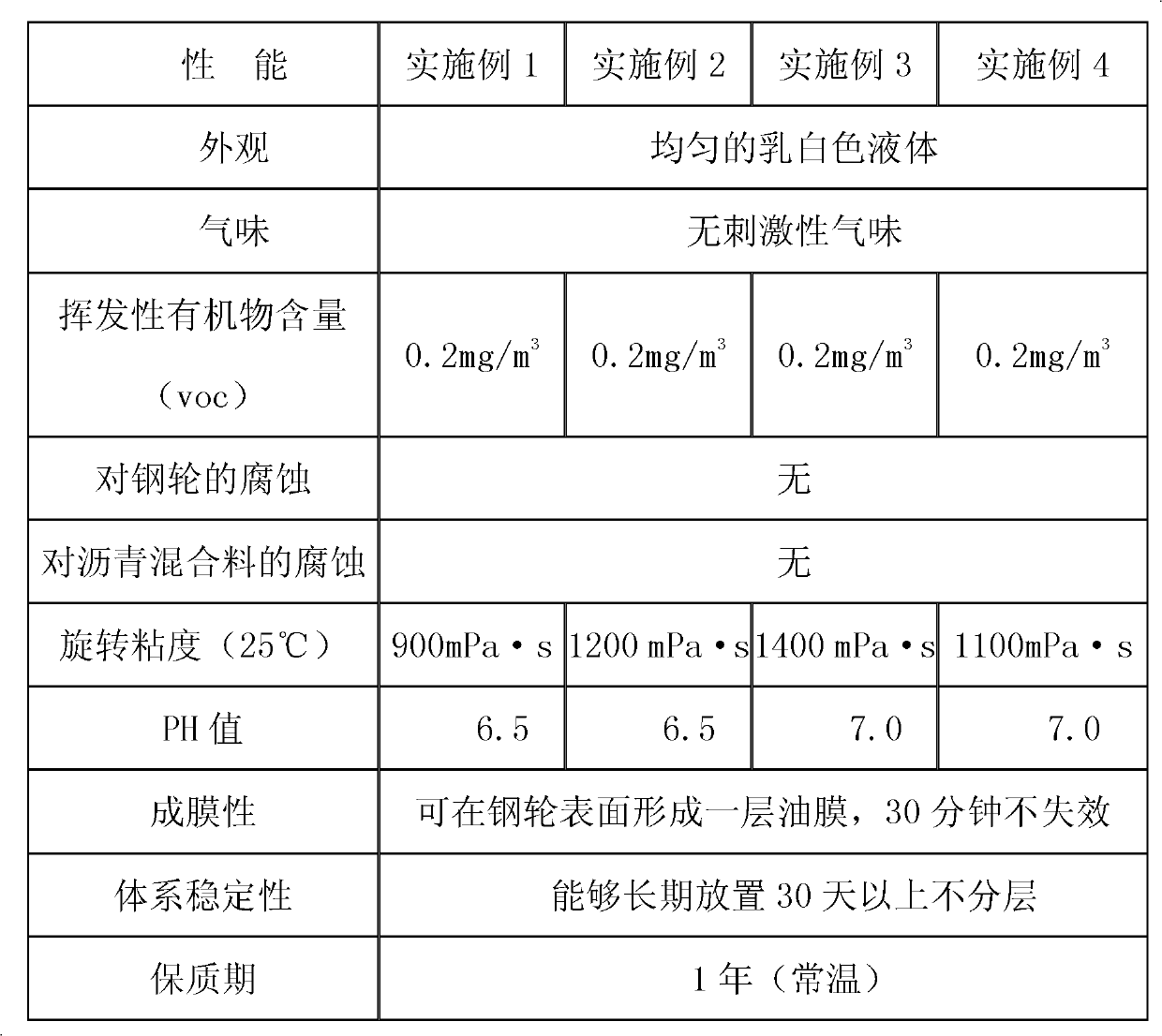

Examples

Embodiment 1

[0028] Experimental raw material components and dosage: 20.4 parts by weight of simethicone oil, 50 parts by weight of a polyvinyl alcohol solution with a concentration of 100 g / L, 10.2 parts by weight of a composite emulsifier, 3 parts by weight of glycerol, 0.3 parts by weight of Glacial acetic acid, the hydroxymethyl cellulose of 0.5 weight part, the sodium benzoate of 0.6 weight part, the water of 15 weight parts;

[0029] The preparation of compound emulsifier: with the Span60 of 3.4 weight parts, the Tween60 of 15.4 weight parts, the Tween80 of 21.4 weight parts, the OP-10 of 8.5 weight parts, the oleic acid of 34.2 weight parts, the low melting point paraffin six components of 17.1 weight parts prepared by mixing

[0030] The preparation method of release agent for asphalt pavement roller is as follows: first preheat each component to 80°C, and add simethicone oil, compound emulsifier, water, and glycerol in the order of 80°C constant temperature water bath to the react...

Embodiment 2

[0032] Experimental raw material components and dosage: 28 parts by weight of simethicone oil, 40 parts by weight of a polyvinyl alcohol solution with a concentration of 100 g / L, 14 parts by weight of a composite emulsifier, 2.5 parts by weight of glycerol, 0.2 parts by weight of Glacial acetic acid, the hydroxymethylcellulose of 0.8 weight part, the sodium benzoate of 0.5 weight part, the water of 14 weight parts;

[0033] The preparation of compound emulsifier: with the Span60 of 3.4 weight parts, the Tween60 of 15.4 weight parts, the Tween80 of 21.4 weight parts, the OP-10 of 8.5 weight parts, the oleic acid of 34.2 weight parts, the low melting point paraffin six components of 17.1 weight parts prepared by mixing

[0034] Concrete preparation method is with embodiment 1.

Embodiment 3

[0036] Experimental raw material components and dosage: 30 parts by weight of simethicone oil, 40 parts by weight of a polyvinyl alcohol solution with a concentration of 100 g / L, 12 parts by weight of a composite emulsifier, 2 parts by weight of glycerol, 0.3 parts by weight of Glacial acetic acid, the hydroxymethylcellulose of 0.5 parts by weight, the sodium benzoate of 0.8 parts by weight, the water of 14.6 parts by weight;

[0037] The preparation of compound emulsifier: with the Span60 of 3.4 weight parts, the Tween60 of 15.4 weight parts, the Tween80 of 21.4 weight parts, the OP-10 of 8.5 weight parts, the oleic acid of 34.2 weight parts, the low melting point paraffin six components of 17.1 weight parts prepared by mixing

[0038] Concrete preparation method is with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com