Granulation method of high-tower melt high-phosphorus compound fertilizer

A compound fertilizer and melt technology, which is applied in urea compound fertilizer, phosphate fertilizer, ammonium orthophosphate fertilizer, etc., can solve the problems of difficult urine fusion and restrictions on the application of high-tower compound fertilizers, achieve rounded particle surface, increase fine density, The effect of improving uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

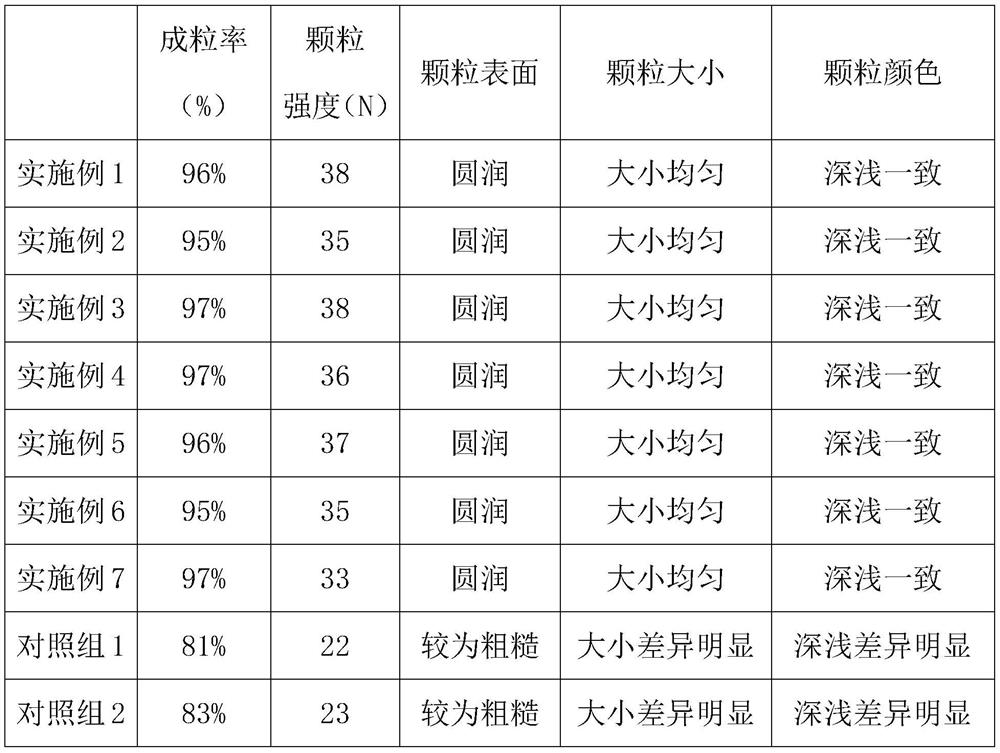

Examples

Embodiment 1

[0032] A granulation process for high-tower melt high-phosphorus compound fertilizer, comprising the following steps:

[0033] a, raw material preparation, by weight, 290 parts of urea containing nitrogen 46%, 360 parts of powdery monoammonium phosphate containing 10% of nitrogen and 50% of phosphorus pentoxide, powdery chlorination of 60% of potassium oxide 220 parts of potassium, 15 parts of sodium sulfate and 8 parts of granulation additive.

[0034] b. Melting, urea is dropped into a melting tank and melted to make urine, the melting temperature is 110°C, the melting time is 55s, and the melting and stirring speed is 50r / min;

[0035] c. Primary mixing, transport the urine to the primary mixing tank, and add powdered monoammonium phosphate containing 10% nitrogen and 50% phosphorus pentoxide for stirring and mixing to make a slurry, the mixing temperature is 85°C, The mixing time is 28s, and the mixing speed is 70r / min;

[0036] c1, a ball mill, transport the mixed slurr...

Embodiment 2

[0042] A granulation process for high-tower melt high-phosphorus compound fertilizer, comprising the following steps:

[0043] a, raw material preparation, by weight, 310 parts of urea containing nitrogen 46%, 480 parts of powdery monoammonium phosphate containing 10% of nitrogen and 50% of phosphorus pentoxide, powdery chlorination of 60% of potassium oxide 300 parts of potassium, 24 parts of sodium sulfate and 15 parts of granulation additives.

[0044] b. Melting, urea is put into a melting tank and melted to make urine. The melting temperature is 120°C, the melting time is 65s, and the melting and stirring speed is 60r / min;

[0045] c. Primary mixing, transport the urine to the primary mixing tank, and add powdered monoammonium phosphate containing 10% nitrogen and 50% phosphorus pentoxide for stirring and mixing to make a slurry. The mixing temperature is 95°C. The mixing time is 32s, and the mixing speed is 80r / min;

[0046] c1, a ball mill, transport the mixed slurry ...

Embodiment 3

[0052] A granulation process for high-tower melt high-phosphorus compound fertilizer, comprising the following steps:

[0053] a, raw material preparation, by weight, 300 parts of urea containing 46% nitrogen, 410 parts of powdery monoammonium phosphate containing 10% nitrogen and 50% phosphorus pentoxide, and 60% powdery chloroform chloride containing potassium oxide 260 parts of potassium, 19 parts of sodium sulfate and 12 parts of granulation additive.

[0054] b. Melting, put urea into the melting tank and melt it to make urine. The melting temperature is 115°C, the melting time is 60s, and the melting and stirring speed is 55r / min;

[0055] c. Primary mixing: transport the urine to the primary mixing tank, and add powdered monoammonium phosphate containing 10% nitrogen and 50% phosphorus pentoxide for stirring and mixing to make a slurry. The mixing temperature is 90°C. The mixing time is 30s, and the mixing and stirring speed is 75r / min;

[0056] c1, a ball mill, the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com