Aluminum-zirconium-carbon sliding plate brick prepared by combining nickel-aluminum alloy-containing organic silicon resin with high-temperature firing and production method of aluminum-zirconium-carbon sliding plate brick

A technology of aluminum-zirconium-carbon sliding brick and nickel-aluminum alloy, which is applied in the field of refractory materials, can solve problems such as insufficient performance, and achieve the effects of improving oxidation resistance, enhancing strength and thermal shock resistance, and stabilizing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

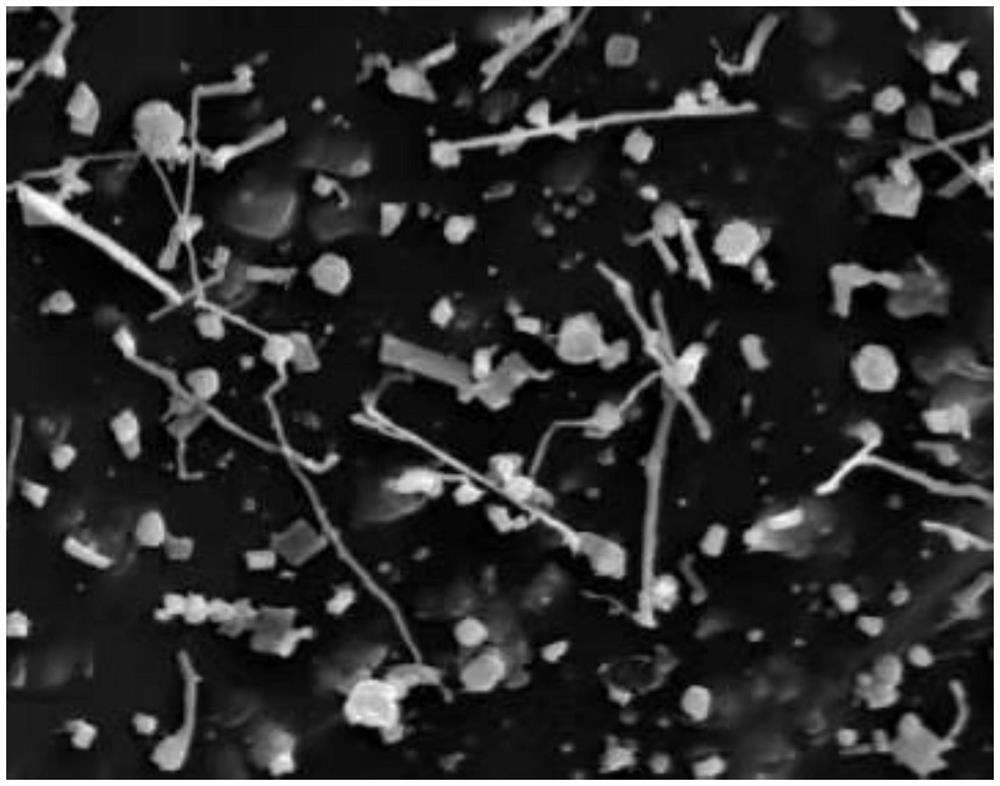

Image

Examples

Embodiment 1

[0034] A nickel-aluminum alloy-containing silicone resin combined with high-temperature firing aluminum-zirconium-carbon sliding brick, the raw materials are composed of 57% tabular corundum, 25% fused zirconia corundum, and 8% activated alumina Micropowder, 3% of monoclinic zirconia, 2% of metallic silicon powder, 3% of carbon black, 1% of carbon-containing resin powder, 1% of boron carbide, plus 3.5% of the total amount of the above raw materials of silicone resin, 0.5 % nickel-aluminum alloy powder.

[0035] The particle size range of tabular corundum is: 1mm<particle size 1≤2mm, 0.5mm<particle size 2≤1mm, 0.044mm<particle size 3≤0.5mm, 0<particle size 4≤0.044mm, and the weight ratio of different particle sizes is: particle size 1: Granularity 2: Granularity 3: Granularity 4 = 15:20:10:12;

[0036] The particle size range of fused zirconia corundum is: 1mm2 o 3: ≥73%, ZrO 2 : ≥25%.

[0037] The particle size of monoclinic zirconia is D50: 3μm, by weight percentage (Zr+H...

Embodiment 2

[0054] A nickel-aluminum alloy-containing silicone resin combined with high-temperature firing aluminum-zirconium-carbon sliding brick, the raw material composition is: 65% corundum, 15% fused zirconia corundum, 11.5% activated alumina micropowder, 2% monoclinic zirconia, 2% metal silicon powder, 2% carbon black, 2% carbon-containing resin powder, 0.5% boron carbide, plus 3.5% organic silicon resin and 0.5% Nickel aluminum alloy powder.

[0055] The particle size range of tabular corundum is: 1mm

[0056] The particle size range of fused zirconia corundum is: 1mm

[0057] The performance parameter of each r...

Embodiment 3

[0059] A nickel-aluminum alloy-containing silicone resin combined with high-temperature fired aluminum-zirconium-carbon sliding brick, the raw materials are composed of 50% corundum, 30% fused zirconia corundum, 11% activated alumina micropowder, 3% of monoclinic zirconia, 2% of metallic silicon powder, 1% of carbon black, 2% of carbon-containing resin powder, 1% of boron carbide, plus 3% of the total amount of the above raw materials of silicone resin, 0.2% of Nickel aluminum alloy powder.

[0060] The particle size range of tabular corundum is: 1mm

[0061] The particle size range of fused zirconia corundum is: 1mm

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com